August 2024 — Prom-nasos.com.ua

August 30, 2024

Installation of a wind turbine

Choosing a wind turbine

The choice of wind turbine depends on your electricity needs. There are different types of wind turbines:

Vertical wind turbines : Suitable for private homes and capable of producing from several hundred watts to several kilowatts of electricity.

Horizontal wind turbines : Used for small commercial enterprises and can produce from a few kilowatts to several tens of kilowatts.

Preparation of Tools and Equipment

To install a wind turbine, you will need the following tools and materials:

Foundation bolts;

Crane or hoist ;

Electrical cables ;

Inverter (for converting alternating current to direct current);

Protective equipment (helmets, gloves, etc.).

Installation of the Foundation

The foundation is an important part of the wind turbine construction. It must be strong enough to support the weight of the generator and withstand strong winds.

Dig a foundation hole according to the dimensions and requirements of your wind turbine.

Install the rebar and pour concrete to create a strong foundation.

Fix the foundation bolts in the concrete until it hardens.

Installation of the Pillar

Once the foundation has hardened, the installation of the pole can begin.

Use a crane or hoist to lift the pole and place it on the foundation.

Fix the post with foundation bolts and check its verticality.

Installation of a wind turbine

The next step is to install the wind turbine itself on the pole.

Lift the wind generator with the crane and attach it to the top of the pole.

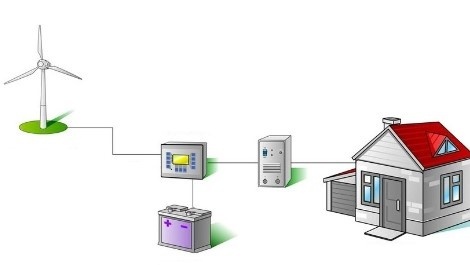

Connect the electrical cables from the generator to the inverter and the energy storage system (battery).

Connect and configure

After the generator is physically installed, it must be connected to the electrical system.

Connect the inverter to the generator and to your power grid.

Adjust the charge controller for optimal operation of batteries .

Check all connections and make sure they are secure.

Testing and Launch

After the installation is complete, test the system:

Check the operation of the wind generator at different wind speeds.

Ensure that electricity is generated and delivered to your grid or storage system.

Adjust settings for optimal performance.

Conclusion

Installing a wind turbine is a complex but important process that will allow you to harness renewable energy to power your home or business. If you follow all the steps correctly, you will be able to ensure stable and reliable operation of your system. If you encounter any difficulties, it is recommended that you contact a professional to install and configure your wind turbine.

August 29, 2024

Types of wind turbines

Wind turbines are an efficient way of harnessing wind energy to generate electricity. They can be used in both private households and commercial enterprises. Wind turbines are an increasingly popular source of renewable energy that harness the power of the wind to generate electricity, reducing dependence on traditional fossil fuels. There are two main types of wind turbines: horizontal and vertical .

Horizontal wind turbines (HAWT)

Horizontal wind turbines are the most common and most efficient. Their blades are perpendicular to the ground and the main shaft is parallel. They resemble classic windmills with long, thin blades. These generators work best at high wind speeds and are often used in large wind farms.

Advantages:

High efficiency under optimal conditions.

Well-developed technologies for large-scale production.

Highest power among available options.

Disadvantages:

High initial cost.

The need for a complex management system.

Vulnerability to strong winds and turbulence.

Vertical wind turbines (VAWT)

Vertical wind turbines have an axis of rotation that is perpendicular to the ground. Their blades are arranged around a shaft, allowing them to operate regardless of wind direction. This makes them ideal for urban environments and locations with variable winds.

Advantages:

Simplicity in installation and maintenance.

Efficient operation at low wind speeds.

Less impact on the environment and aesthetic appearance.

Disadvantages:

Lower efficiency compared to horizontal wind turbines.

Limited power making them less suitable for large projects.

Conclusion

The choice between horizontal and vertical wind turbines depends on the specifics of the terrain, climatic conditions and power requirements. For large wind farms with high wind speeds, horizontal wind turbines are the best option. At the same time, vertical wind turbines are ideal for urban environments and locations with variable wind conditions, where their versatility and simplicity are key advantages.

Pumping equipment with a high capacity, and therefore a large volume of water that can be moved per unit of time, makes up a much smaller percentage of the total number of pumps used in industry and agriculture.

These pumps are used by local water utilities, heat supply companies to supply drinking water or heat supply of villages, towns or even entire neighborhoods of large cities. In addition, these pumps can be used for water lowering , water storage for irrigation and irrigation in agriculture , pumping water from construction pits, etc.

As a rule, when the question arises of quick delivery of a pump whose power is greater 20-30 kW , to start production or solve an emergency situation, the supply department faces the problem of long delivery times and prices.

Our company is ready to offer high-capacity pumps in stock in Ukraine at the best prices.

In particular, these are compact (despite high power) pumps of the design in-line .

For example, there are such models available as IRG 200-315(I) , IRG 100-200 (I) , IRG 200-315 (I) A.

These pumps are very convenient to install, as the motor is placed vertically, and the pressure and suction nozzles are on the same line. The vertical placement of the motor also prevents the electric motor from flooding if the end seal is damaged.

Self-priming and normally aspirated pumps

Theory

The maximum theoretical depth from which any pump on planet Earth can raise a liquid is minus one physical atmosphere, in meters of the water column, it is approximately 10.3 m. That is, there is no pump that can draw a liquid from a greater depth (no centrifugal , not vacuum , or diaphragm or any other).

Another misconception is that a pump with a power of, for example, 11 kW can ‘pull’ liquid from a greater depth than a pump with a power of 0.55 kW. The power of the pump affects its capacity and pressure, and has no bearing on the depth from which it can draw fluid.

Practice

Normal suction pumps

In fact, the vast majority of pumping units are normally suction pumps. This includes the entire group of centrifugal pumps, which are dynamic pumps (with a spiral impeller, vortex, radial or other). These pumps cannot self-priming (pull liquid without being primed) because when they start up, without liquid in the working chamber, they are essentially pumping air, and since the density of air is much lower than that of any liquid, the suction force (vacuum) is not sufficient.

In order to start such a pump unit, it is necessary to first fill the working chamber of the pump with liquid (water, alcohol , ethylene glycol, milk etc.). In addition, if the liquid level is below the axis of the suction pipe, a non-return valve must be installed at the end of the pipe, so that after stopping the pump, the liquid remains in the working cavity and it is possible to start working again.

A group of pumps with a pre-priming chamber should be selected separately. Although they are conventionally called self-priming, in fact these pumps are also normally priming and also require the presence of liquid in the working chamber to start work. The only difference is that you only need to fill the pump once, since the presence of a pre-filling chamber allows you to keep a reserve of liquid sufficient to start the pump. Accordingly, this feature allows the use of such pumps without a non-return valve.

Self-priming pumps

In most cases, when people talk about a ‘self-priming’ pump, they mean a unit that can draw liquid without pre-filling, simply by throwing a hose or lowering a pipe into the liquid.

Displacement pumps have this property - piston, diaphragm , impeller , peristaltic , roller pumps etc. The principle of operation of these pumps is based on a change in the volume of the working chamber, as a result of which they can draw liquid without filling.

This feature is very useful when working with aggressive substances, such as acids, alkalis, mineral fertilisers and other liquids, when it is not possible to fill the working chamber.

This group includes the vast majority of pipette pumps (plunger, diaphragm, peristaltic). Simply lower the suction nozzle (hose) into the reagent and switch on the pump, and the process of filling the working chamber and further operation will begin automatically.

4 posts