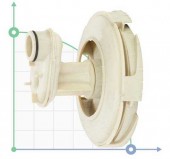

Diffuser

Knowing the internal structure of these hydrophore pumps, you can easily carry out an independent repair by replacing the failed part and restoring the pumping station to work properly. Before starting to repair the pump, it is necessary to drain the remaining water from it and disconnect all connected devices: expansion tank, pressure switch, pressure gauge and others. So, let's get down to the analysis.

To access the internal parts, detach the front of the pump (housing), which is bolted to the rear. Unscrewing them, remove the pump housing. A diffuser and a guide, connected to each other, are installed in the housing.

If the cause of the hydrophore malfunction is the breakdown of these parts, then you just need to replace them with new ones and assemble the hydrophore in the reverse order.

If the reason is not in them, then it is necessary to look for a malfunction in another part of the pump.

The back of the pump consists of the electric motor itself, on the shaft of which an impeller is installed - the main mechanism that allows the pump to pump water. The motor is attached to the console, and a special ceramic oil seal prevents water from leaking through the shaft. In order to disconnect the impeller, you must unscrew the bolt that secures it. But since the impeller is mounted on a rotating shaft, it is not so easy to do this.

| Producer | AQUATICA |

| Material | tecnopolymer |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | tecnopolymer |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | tecnopolymer |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | Cast iron |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | tecnopolymer |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | tecnopolymer |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | tecnopolymer |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | Cast iron |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | Cast iron |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | Cast iron |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | Cast iron |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | Cast iron |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | Aluminium alloy |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | tecnopolymer |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | tecnopolymer |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | tecnopolymer |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | tecnopolymer |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | tecnopolymer |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | tecnopolymer |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | tecnopolymer |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | stainless steel |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Material | stainless steel |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Country of Origin | China |

| Application | for pumps Aquatica |

| Producer | AQUATICA |

| Country of Origin | China |