- Home

- Industrial pumps

- Pumps by liquidsBitumen pumpsEx pump for draining bilge liquidsNitric acid pumpPump for dosing hypochlorite, chlorinePump for liquid glassPump for fatPump for potassium bichromate, caustic sodaPump for cream and pastePump for fish and seafoodPump for syrupSour cream pumpPump for hydrocarbonsPump for minced meatPump for chocolate and massPump for emulsions and suspensionsPump for spice and saltPump for cheese grainPump for the extractPumps for ammonia water, ammonium hydroxide NH4OHPumps for stillage, mashWine pumpsWater pumpsPumps for viscous liquidsPumps for hexaneGlycerin pumpsLiquid feed pumpsPumps for UANPumps for ceramic slipAcid pumpsGlue pumpsPumps for paints and varnishesFuel oil pumpsMilk pumpsPumps for an ice creamPumps for urea, liquid fertilizers, ammoniaPumps for petroleum products, gasoline, diesel fuelMolasses pumpsSuperheated water pumpsPermeate PumpBeer pumpsChemical dosing pumpsPumps for giblets and slaughter wasteVegetable oil pumpsResin pumpsPumps for pumping alcohol ЕХSewage and sewage pumpsFertilizer pumpsPumps for freonSlurry pumpsLye pumpsEthylene glycol pumpsAcid-resistant pumps for aggressive liquidsThermal oil pumps +350Food pumps for juice, concentrate

- Thermal oil pumps +350

Thermal oil pumps +350

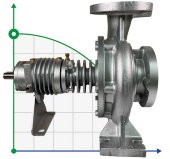

Thermal oil pumps

Bitumen heating station pumps, thermal oil pumps, oil heating station pump.

Heating bitumen storage and bitumen-smelting plants ("evaporators") using hot oil as a heat carrier, which is supplied to the system by a circulation pump and this is considered the most progressive and efficient from an economic point of view.

In oil-heated systems, the heated high-temperature heat carrier (oil) is circulated by a pump through the pipe system of heat exchangers located inside the tanks and reservoirs with bitumen. Unlike systems based on heating elements and fire-tube boilers, bitumen overheating in the zone of contact with the heat exchanger does not occur due to the lower temperature of the latter. The transfer of the required amount of heat is carried out due to a more developed system heat transfer: the oil circulated by the pump as a heat carrier allows this to be done. With this method heating, oxidation and coking of bitumen is excluded, accordingly, there is no deterioration in its quality characteristics.

Oil, unlike steam, has constant parameters and can provide any required temperature heating mode in a wide range - from 90 to 160 °С. The advantage of the oil system over steam, heating elements and a flame tube, it is also possible to combine bitumen storage, bitumen-melting boilers and bitumen pipelines into a single heating system, which will be based on an oil heating station.

It is also important that oil heating systems are not under excessive pressure.

Descriptions

| Cast iron | 0.6025 | EN-GJL-250 (GG 25) | A 48 Class 40-B |

| Malleable Iron Casting | 0.7040 | EN-GJS-400-15 (GGG 40) | A 536 60-40-18 |

| Chrome Nickel Molybdenum Casting Steel | 1.4408 | GX5 Cr Ni Mo 19-11-1 | A 351 CF8M |

| Chrome steel | 1.4021 | X 20 Cr 13 | A 276 Type 420 |

| Chrome Nickel Molybdenum Steel | 1.4301 | X5 Cr Ni 18-10 | A 276 Type 304 |

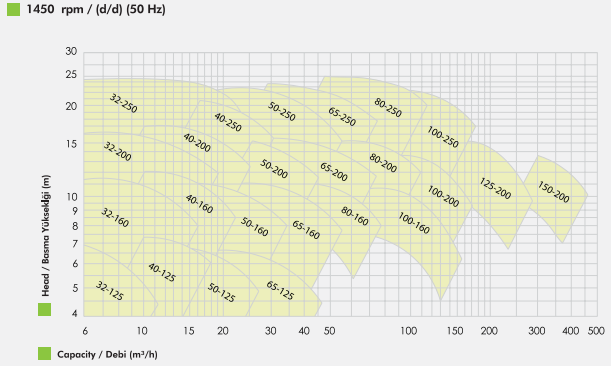

Selection charts

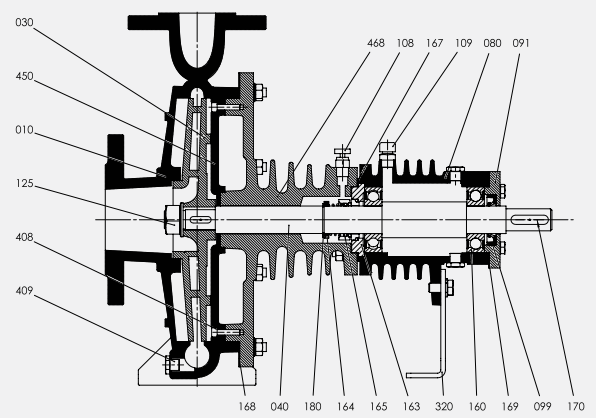

Incision

Parts List

| Spiral Body | 010 | Mechanical seal | 165 |

| Impeller | 030 | Mechanical Seal Gasket | 167 |

| Shaft | 040 | Body seal | 168 |

| Bearing shell | 080 | Bearing Cover Gasket | 169 |

| Bearing Cover | 091 | Key | 170 |

| Stuffing box | 099 | Val's Ring | 180 |

| Blowing | 108 | Support Legs | 320 |

| Airlock | 109 | Bolt | 408 |

| Cam | 125 | Drain plug | 409 |

| Bearing | 160 | Plate | 450 |

| Mechanical seal | 163 | Casing Cover | 468 |

| Mechanical Seal Positioning Sleeve | 164 |

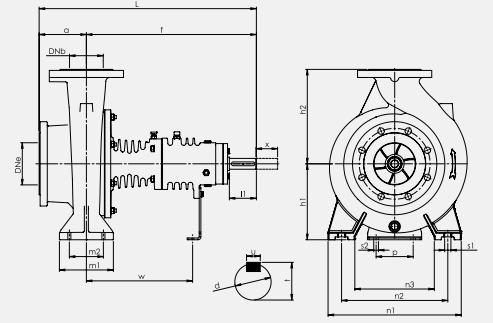

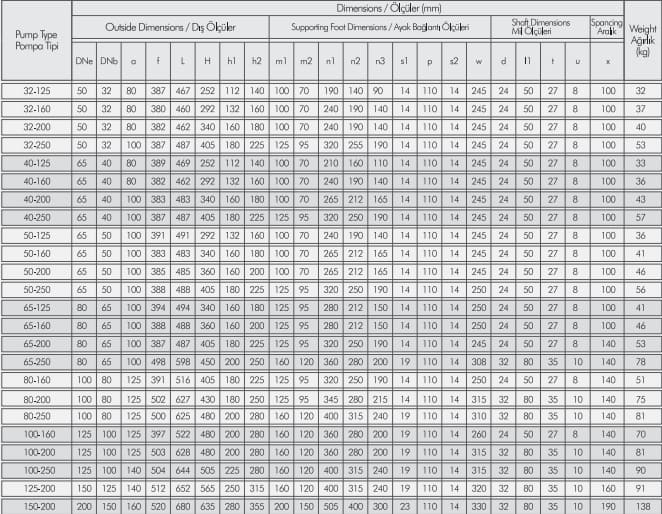

Pump dimensions

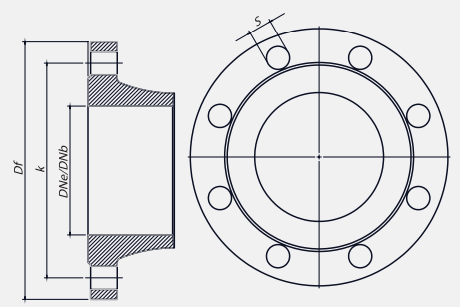

Flange Dimensions

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, m3/h | 2.52 |

| Feed height, m | 28 |

| Power capacity, kW | 0,37 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, m3/h | 2.52 |

| Feed height, m | 28 |

| Power capacity, kW | 0,37 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, m3/h | 1.8 |

| Feed height, m | 15 |

| Power capacity, kW | 0,25 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, m3/h | 1.8 |

| Feed height, m | 15 |

| Power capacity, kW | 0,25 |

| Producer | EMSE |

| Power capacity, kW | 11 |

| Material | cast iron |

| Input pipe diameter | DN65 |

| Output pipe diameter | DN40 |

| Producer | ERDURO |

| Pump capacity, m3/h | 38 |

| Feed height, m | 48 |

| Material | cast iron |

| Input pipe diameter | DN50 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, m3/h | 3.36 |

| Feed height, m | 38 |

| Power capacity, kW | 0,75 |

| Producer | EMSE |

| Power capacity, kW | 11 |

| Material | cast iron |

| Input pipe diameter | DN65 |

| Output pipe diameter | DN50 |

| Producer | EMSE |

| Power capacity, kW | 18,5 |

| Material | cast iron |

| Input pipe diameter | DN80 |

| Output pipe diameter | DN65 |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 4 |

| Feed height, m | 32 |

| Power capacity, kW | 1,5 |

| Material | carbon steel |

| Producer | ERDURO |

| Pump capacity, m3/h | 40 |

| Feed height, m | 65 |

| Power capacity, kW | 4, 5,5, 7,5, 11 |

| Material | cast iron |

| Producer | ERDURO |

| Pump capacity, m3/h | 130 |

| Feed height, m | 47 |

| Power capacity, kW | 11, 15, 18,5 |

| Material | cast iron |

| Producer | ERDURO |

| Pump capacity, m3/h | 80 |

| Feed height, m | 11 |

| Material | cast iron |

| Input pipe diameter | DN100 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, m3/h | 8.4 |

| Feed height, m | 85 |

| Power capacity, kW | 2,2 |

| Producer | EMSE |

| Power capacity, kW | 15 |

| Material | cast iron |

| Input pipe diameter | DN50 |

| Output pipe diameter | DN32 |

| Producer | EMSE |

| Power capacity, kW | 15 |

| Material | cast iron |

| Input pipe diameter | DN65 |

| Output pipe diameter | DN40 |

| Producer | EMSE |

| Power capacity, kW | 37 |

| Material | cast iron |

| Input pipe diameter | DN80 |

| Output pipe diameter | DN65 |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 4.5 |

| Feed height, m | 50 |

| Power capacity, kW | 3 |

| Material | carbon steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6.3 |

| Feed height, m | 50 |

| Power capacity, kW | 4 |

| Material | carbon steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 12.5 |

| Feed height, m | 50 |

| Power capacity, kW | 5,5 |

| Material | carbon steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 25 |

| Feed height, m | 50 |

| Power capacity, kW | 7,5 |

| Material | carbon steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 25 |

| Feed height, m | 80 |

| Power capacity, kW | 15 |

| Material | carbon steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 50 |

| Feed height, m | 50 |

| Power capacity, kW | 15 |

| Material | carbon steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 50 |

| Feed height, m | 80 |

| Power capacity, kW | 22 |

| Material | carbon steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 100 |

| Feed height, m | 50 |

| Power capacity, kW | 22 |

| Material | carbon steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6.3 |

| Feed height, m | 50 |

| Power capacity, kW | 4 |

| Material | carbon steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 25 |

| Feed height, m | 50 |

| Power capacity, kW | 7,5 |

| Material | carbon steel |

| Producer | ERDURO |

| Pump capacity, m3/h | 17 |

| Feed height, m | 11 |

| Power capacity, kW | 0,37, 0,75, 1,1 |

| Material | cast iron |

| Producer | ERDURO |

| Pump capacity, m3/h | 22 |

| Feed height, m | 12 |

| Power capacity, kW | 0,55, 0,75, 1,1 |

| Material | cast iron |

| Producer | ERDURO |

| Pump capacity, m3/h | 12 |

| Feed height, m | 7.5 |

| Power capacity, kW | 0,15, 0,25, 0,37 |

| Material | cast iron |