September 2025 — Prom-nasos.com.ua

September 10, 2025

Lobe pumps for viscous products

Lobe pumps (rotary, vane, flap) with a steam jacket are a type of pumping equipment specially designed for products that tend to solidify or crystallize quickly when the temperature drops.

The pump design incorporates the “steam jacket” method, which includes two types: the pump body or the pump cover. Steam or hot water can be supplied to the body or cover of the pump to maintain a constant temperature of the working chamber. This effectively prevents seal damage caused by material solidification during start-up.

The steam jacket can be widely used for products whose viscosity is highly affected by temperature. These pumps can be used in the production of sugar, chocolate, pharmaceuticals, butter, and more.

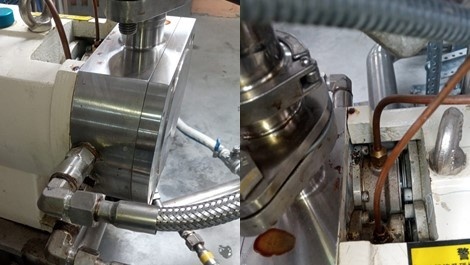

Lobe pump for pumping caramel at 140°C

Applications:

The rotary food pump can be used to transport all kinds of materials with medium and high viscosity as well as high solid content.

Lobe pumps are widely used in the production of sugar, chocolate, dairy products, various syrups, concentrated fruit juice, jelly, yogurt, honey, ice cream, cake fillings, cereal porridge, soy protein, meat fillings, seasonings, tomato paste, caramel, bean paste, and other products.

September 5, 2025

Replacement of Wilo MHI series pumps with Medana series pumps

A well-known German manufacturer of pumping equipment, Wilo (Dortmund, Germany), whose official representative is our company, has discontinued the popular in Ukraine horizontal multistage pumps of the MHI series due to the release of new, more energy-efficient pumps.

Pump of the MHI series

Despite their external appearance (the pumps look almost identical).

Pump of the Medana series

The Medana series pumps are equipped with a more energy-efficient electric motor and an improved hydraulic section.

As before, by purchasing pumps from this manufacturer, you get high quality at an affordable price.

Pumps of this series are characterized by high hydraulic efficiency, reliability, and maintainability.

September 2, 2025

Filters for electroplating

Galvanization, that is, coating one type of metal (usually steel) with a thin layer of another metal (nickel, zinc, chrome, etc.) in order to protect it from corrosion or as a decorative coating.

The basis of galvanization is the electrolytic process, when a part or workpiece is immersed in a bath with electrolyte. During production, the electrolyte becomes contaminated with mechanical impurities and precipitates formed as a result of the electrolytic process.

Since the electrolyte becomes contaminated, there is a need for its purification. The electrolyte contains acids, metals, and salts of relatively high value, so its reuse is economically justified.

The simplest and quite effective way of purifying the electrolyte is the use of mechanical filters.

In essence, this process is very similar to water purification, with the difference that the materials used to manufacture the pump and the filtration unit must be chemically resistant.

Our company offers both separate chemically resistant plastic pumps (polypropylene, PVDF, PVC) as well as ready-made filtration units .

The advantage of a filtration unit, at a relatively low cost, is the presence of all necessary elements to implement the purification process almost immediately, straight out of the box.

The filter housing is equipped with Slim 20-inch filter elements. These elements are available to order with different pore sizes — 5-10-25-50-100 µm.

3 posts