November 2025 — Prom-nasos.com.ua

November 28, 2025

The HRS32/7 circulation pump – a quiet and reliable solution for your heating system

Every heating system requires a pump that ensures stable circulation of the heat transfer fluid. Without it, heat simply does not reach all radiators, and the boiler operates inefficiently.

One of the best options for residential and small commercial systems is the HRS32/7 circulation pump with a wet rotor . It is a simple, reliable, and proven solution that has shown excellent results in practice.

What is the HRS32/7 pump and how does it work?

This pump features a wet rotor, meaning the rotating components are in contact with the liquid inside the system. As a result, the heat transfer fluid lubricates and cools the mechanism itself, so the pump requires no additional maintenance and operates almost silently.

The HRS32/7 is designed for continuous circulation of water or heat transfer fluid in heating and domestic hot water systems. Its construction is optimized to ensure stable pressure even in branched, multi-floor installations.

Main specifications

Connection size — DN32 (2")

Maximum head — up to 7 m

Flow rate — up to 3.7 m³/h

Three rotation speeds (manually adjustable)

Durable cast-iron housing

Low noise level

Advantages of the HRS32/7 pump

Quiet operation. The wet rotor ensures smooth performance without humming or vibrations. Ideal for residential spaces.

Energy efficiency. With three speed settings, you can choose the optimal mode and avoid unnecessary power consumption.

Durability and reliability. Its simple design allows the HRS32/7 to operate stably for many years without the need for frequent maintenance.

Easy installation. The pump can be easily integrated into standard heating systems — the threaded connections fit most pipes.

Availability of spare parts. This model is popular, so seals, nuts, and other spare components are easy to find on the market.

The HRS32/7 pump is ideal for:

heating systems in private homes;

underfloor heating;

domestic hot water circulation;

small commercial facilities.

Conclusion

If you are looking for a quiet, efficient, and reliable circulation pump for your heating system, the HRS32/7 is exactly what you need. It combines proven quality, a simple design, and a reasonable price.

The pump is available in our warehouse, and you can purchase the HRS32/7 directly on our website. If needed, we can also provide consultation on selection or installation.

The HRS32/7 circulation pump is a simple solution that works reliably for years.

November 24, 2025

BMS battery system lockout: why it happens and what to do about it

If the battery has stopped working, is not charging, or appears “dead”, even though everything seemed fine before — most likely the BMS protection has been triggered.

BMS is a Battery Management System. It ensures that all cells operate without overload, overheating, or short circuit. If something goes wrong, it simply “turns off” the battery to prevent damage to both the battery and the connected equipment.

Why the BMS locks

1. Over-discharge or overvoltage.

If even one cell is discharged below the allowed level or the voltage exceeds the norm, the system disconnects the battery. This is a common situation when the battery has been unused for a long time or is charged with an inverter that is too powerful.

2. Overheating or overcooling.

At temperatures below 0 °C, charging is prohibited because lithium crystals form inside the cells. In hot conditions above 50 °C, a lockout may also occur — to prevent ignition.

3. Excessive load or short circuit.

If the system “sees” that the current exceeds the allowed value, it disconnects instantly. This often happens due to improper inverter connection, especially if there are startup surges.

4. Cell balancing problems.

Over time, cells age unevenly and their voltages drift apart. The BMS detects this and reacts — especially during charging to 100%.

5. Loss of communication or firmware error.

In complex systems with CAN or RS485, any communication failure may cause a lockout, even if the cells themselves are fine.

How to unlock the system

1. Check the voltage at the terminals.

If the voltage is “0”, it does not mean the battery is empty. The BMS has simply disconnected the output. First, connect a control multimeter to each section or use the diagnostic port if available.

2. Try to “wake up” the BMS with a short charge.

In most cases, applying a small charging current (0,05–0,1 C) for a few minutes is enough for the system to exit sleep mode. Some LiFePO4 packs “wake up” even after a few seconds of applied voltage.

3. Cell balancing.

If the lockout is caused by voltage imbalance, the battery must be left on a charger in balancing mode (sometimes for several hours). The BMS will automatically level the cells and allow discharge.

4. Reset via service software.

Most “smart” BMS units (JBD, Daly, ANT, Seplos, Overkill Solar, etc.) have PC or smartphone apps. Through them, you can read errors and manually reset the lockout. However, it is important to eliminate the cause first, otherwise the system will lock again immediately.

5. Protection against deep discharge.

If the battery has been unused for a long time (especially for several months), the voltage may drop so low that the BMS “falls asleep”. In this case, you need a laboratory power supply with adjustable voltage to gradually “raise” the cells to a safe level.

6. Firmware update (for experienced users only).

If the BMS is “frozen” and unresponsive — re-flashing may help. However, do this only if you are confident in your skills, because a mistake can permanently damage the controller.

How to avoid repeated lockouts

Do not allow deep discharge — use a power management system or backup charging.

Do not use the battery in freezing temperatures without heating.

Every few months, check cell balance through the app or communication port.

If the battery is not in use, keep the charge level at 50–60% and store it in a dry place at +15…+25 °C.

And most importantly — never short the terminals manually in an attempt to “bypass” the BMS. This can cause smoke and burning smell.

Conclusion

BMS lockout is not a failure — it is protection from failure. It responds not to “whims”, but to real threats to the battery. If you understand the causes and act calmly, 90% of cases can be resolved without replacing the battery.

The main thing — do not panic, do not randomly poke wires, and always have a good multimeter or monitoring app at hand.

November 21, 2025

Butterfly valves: a reliable solution for modern pipelines

Today, in water supply, heating, ventilation, and industrial systems, butterfly valves — also known as disk valves — are used more and more often. These are compact and efficient fittings designed to shut off or regulate the flow of liquids or gases in pipelines.

Where butterfly valves are used

Such valves are used in:

water supply and sewage systems;

district heating networks and ventilation systems;

the food, chemical, and pharmaceutical industries;

installations using technical or seawater, as well as various industrial processes where reliable shut-off valves are required.

Thanks to their simple yet well-designed construction, a butterfly valve can be installed quickly even in hard-to-reach places — which is especially convenient for maintaining large systems.

Main advantages of butterfly valves

Compact size and low weight. Compared to traditional gate valves, these models take up less space and are easier to install.

Reliable operation. Tightness is ensured by a special sealing sleeve, which guarantees durability even under high pressure.

Easy maintenance. The design minimizes the risk of jamming, and replacing sealing components does not require complex tools.

Affordable price. Butterfly valves are significantly cheaper than traditional steel or cast-iron gate valves.

Option for manual or electric actuation. This allows their use in automated systems.

Ordering butterfly valves in our store

On our website prom-nasos.com.ua, you can order a butterfly valve at a competitive price. We offer certified products proven in practice, as well as expert consultations to help you choose a reliable solution for your specific working conditions.

Butterfly valves are an effective solution for those who need durability and ease of operation.

November 14, 2025

COLOMBO frame filter press

COLOMBO Frame Filter Press – a reliable solution for efficient filtration.

In any production process where it is necessary to separate liquid from solid particles, it is important to have equipment that operates reliably and without unnecessary complications. One such unit is the COLOMBO frame filter press, which has proven itself as dependable equipment for purifying suspensions across various industries — from the food sector to water treatment.

Purpose of the filter press

The COLOMBO filter press is designed for mechanical dewatering of sludge and for removing solid impurities from liquids. Its operating principle is simple yet highly effective: the suspension is fed into chambers between the filter plates, where it passes under pressure through the filter cloth. As a result, clean liquid (filtrate) is obtained on one side, and a dense solid cake (filtration “cake”) on the other.

Technical specifications (example: COLOMBO 12)

Design type: frame-plate

Number of plates: 12

Clamping system: manual

Filter cloth dimensions: standard, easy to replace

These parameters make this filter press convenient for use both in small enterprises and in agricultural applications.

Main advantages of COLOMBO

Ease of maintenance. The filter press design is well thought out: easy access to the plates, quick cloth replacement, and a minimum number of moving parts.

High filtration quality. Fine filtration ensures a very clean filtrate even when working with dense suspensions.

Durability. The materials used are resistant to corrosion, aggressive environments, and temperature fluctuations.

Cost-effectiveness. The filter press requires low energy consumption, and the use of consumables is minimal.

Versatility. Suitable for the food, chemical, pharmaceutical, and other industries.

Compact design. Takes up little space, which is beneficial for production areas with limited room.

This filter press is available in our warehouse, so there is no need to wait for delivery. You can purchase it today and put it into operation immediately.

November 11, 2025

Alpha-amylase and glucoamylase

Alpha-amylase and glucoamylase are enzymes used in the food, alcohol, biotechnology, starch-processing and other industries.

The use of enzymes in alcohol production is a key stage, as they increase reaction speed and provide a higher alcohol yield, which in turn makes the production process more efficient. Enzymes break down complex carbohydrates into simple sugars, which then undergo alcoholic fermentation with the participation of yeast.

The activity of enzymes is influenced by factors such as temperature, fermentation time and pH level. Maintaining these conditions ensures optimal starch breakdown and the decomposition of other complex compounds.

Alpha-amylase breaks down starch into shorter dextrin chains.

Optimal operating temperature – 85–95˚C. Optimal pH level – 5.8–6.2.

Glucoamylase converts dextrins into glucose, which is then fermented by alcohol yeast into ethanol.

Optimal operating temperature – 56–60˚C. Optimal pH level – 4.0–4.8.

A set of enzyme preparations is available for sale, which includes 50 ml of alpha-amylase and 50 ml of glucoamylase.

This is the optimal enzyme dosage for producing distillates at home, calculated for 200 kg of grain (flour).

In combination with enzymes, yeast must be used for the production of alcoholic beverages. Cold fermentation alcohol yeast Kodzi Angel Leaven has proven to be highly effective.

November 10, 2025

Dreno ALPHA submersible pumps

Dreno ALPHA submersible pumps are designed for pumping liquids (usually contaminated or containing impurities) and are installed fully submerged in the working medium.

Areas of application:

pumping out septic tanks, cesspools, and sewage wells;

drainage of basements and flooded premises;

drying wells, ponds, and construction pits;

pumping technical and rainwater.

Operating characteristics:

Maximum liquid temperature: 40°C with the pump fully submerged;

Maximum immersion depth: 20 m;

Permissible pH range: 6–10;

Hydraulic performance is valid for liquids with density <1.1 kg/dm3;

Permissible voltage: 220 V/380 V ±5%;

The pump casing and impeller are made of GG20 cast iron;

Cooling is provided by the liquid in which the pump is submerged.

We offer a wide selection of Dreno pumps and, if needed, spare parts for them.

November 7, 2025

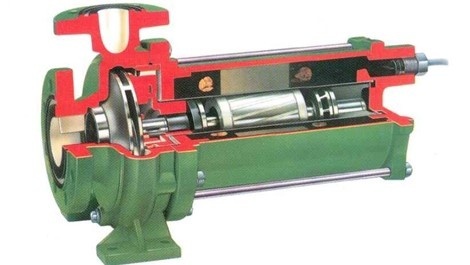

Operation of a centrifugal pump under vacuum

First, a bit of theory.

NPSH — “Net Positive Suction Head,” also known as the cavitation margin — is the most important parameter for evaluating a pump’s suction capability. NPSH defines the minimum pressure at the pump inlet required for cavitation-free operation.

There are two NPSH values: NPSHr (“required”) — the required cavitation margin, i.e., the minimum pressure needed at the pump suction nozzle. NPSHr for each pump is determined through factory testing and indicated on graphs and in tables (see Fig. 1). Note that these data are provided for liquid temperature of +20°C.

Fig. 1

Comparison of NPSH values for pumps operating at 1500 and 3000 rpm.

NPSHa (“available”) — the available suction head in the system where the pump is installed. Since pumps operate within a system ( heating, water supply, wastewater , alcohol production , food processing, etc.), pump performance depends largely on the piping layout, the system configuration, shut-off valves , automation , and not only on the pump's construction or manufacturer.

NPSHa (system) must always be greater than NPSHr (pump)

NPSHa > NPSHr

This condition must be met for proper, cavitation-free pump operation.

Let us consider an example of pump operation when pumping liquid from a vessel under vacuum. This could be, for example, a chemical reactor or a distillation/fermentation column , from which stillage is being removed.

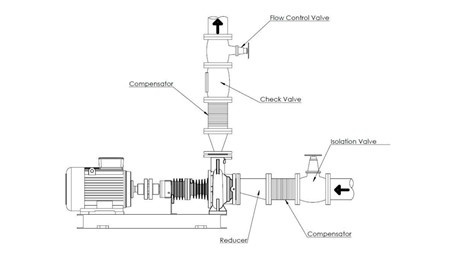

The basic scheme of such a process is shown in Fig. 2

The engineering design is shown in Fig. 3

Fig. 2

Fig. 3

NPSHa for a system operating under vacuum is calculated using the following formula:

NPSHa = P + Lh − (Vp + Hf)

P — pressure above the liquid surface in a closed vessel (gauge pressure);

since the vessel is under vacuum, we assume P = 0 (absolute vacuum, although in real systems absolute pressure will never be exactly zero)

Lh — maximum static head (flooded suction height);

Vp — vapor pressure of the liquid at the maximum operating temperature;

Hf — friction losses in the suction pipeline at the required pump flow rate;

From this formula, we can conclude that to increase the pump’s suction capability, one must increase the liquid column height (Lh), reduce the vapor pressure (Vp) — since it depends on temperature, cooler liquid is preferable — and reduce friction losses in the pipeline (increase suction pipe diameter, install shut-off valves of larger diameter).

As shown in Fig. 1, it is preferable to use pumps operating at 1500 rpm instead of 3000 rpm.

November 6, 2025

Choosing a battery for an inverter and UPS

Our company specializes in selling batteries of various voltages from manufacturers ROSEN and Cooli .

The batteries are compatible with hybrid inverters and/or uninterruptible power supplies (UPS) from 12 to 24 V – “low-voltage” – and 44–56 V (“high-voltage”).

We would like to note that when choosing LiFePO4 batteries, there are several important nuances:

It is important (!) to know the specifications of the inverter or UPS to which the LiFePO4 battery will be connected.

The voltage of the average expected energy consumption.

The amount of time during the day for which the batteries must provide power.

We will select a battery from a certified manufacturer

November 5, 2025

Installation of a thermal oil circulation pump and piping

Since this pumping equipment operates with a heat transfer medium based on thermal oil at high temperatures (from 130 to 350 °C), pump installation, motor connection, electrical wiring, and pipeline assembly may only be performed by qualified personnel.

The following rules must be observed during pump installation:

Remove protective covers from the flanges.

The pump must be installed in locations free from the risk of freezing or explosion and where good ventilation is ensured.

There must be sufficient space around the pump to allow convenient installation and maintenance.

The suction pipe should be as short as possible.

The pump assembly must be placed on a steel support frame and securely fastened using bolted connections. The frame structure must be rigid enough to prevent vibration during operation and must also allow adjustment of the motor position relative to the pump.

The support frame should be mounted on a horizontal concrete base using anchor bolts or by welding to embedded steel elements.

Pump installation

The pump may only be installed in a horizontal shaft position.

Pumps up to 5–10 kW are installed on a metal frame, while more powerful pumps require a foundation. The concrete foundation must weigh at least twice as much as the pump with the motor. The length and width of the foundation should exceed the frame dimensions by 100 mm on each side. If necessary, vibration isolation should be used for high-power pumps.

The pump casing is mounted on the frame or foundation with bolts through the mounting foot holes.

For proper cooling of the motor, the distance from the nearest structure must be at least 0.5 m.

During thermal insulation, only the pump casing (volute) and the connection nozzles may be insulated. Insulating the motor is strictly prohibited.

Before installation, ensure that the shaft rotates freely by turning it via the coupling after removing the cover.

Before connecting the pump, flush the pipelines to remove scale, slag, and other contaminants.

Connection to the pipeline

The working medium enters through the axial inlet and exits through the radial outlet of the centrifugal pump.

The diameters of the inlet and outlet pipelines are selected based on calculations and are usually 1–2 nominal sizes larger than the pump nozzles.

The pump casing must not be subjected to twisting, stretching, bending, or compression caused by the connected pipelines. For maintenance, shutoff valves must be installed before and after the pump. The shutoff section must include a drain valve.

To protect the pump from damage by solid particles, install a mesh strainer before the pump.

To eliminate vibration transfer to the connected pipelines, use anti-vibration connectors on the suction and discharge lines.

In multi-pump parallel installations, a check valve must be installed on the discharge side of each pump.

For flanged joints, place a washer between the nut/bolt head and the flange.

The pipeline flanges must be parallel to the pump flanges, with gaskets suitable for the parameters of the pumped medium.

Install pressure gauges before and after the pump to monitor operation.

The pump must not be used as a support point or structural element for the pipeline.

Pipelines must be supported as close to the pump as possible. Ensure that the weight, stress, or deformation of the pipeline is not transferred to the pump.

Excessive pipeline stress can cause leakage of the working medium.

The nominal nozzle dimensions do not determine the pipe diameter selection. The pipe diameter must be equal to or larger than the nozzle diameter. Using pipes or fittings of smaller diameter is prohibited.

Connections must be made with flanges and appropriately sized gaskets of suitable material. The gasket must be centered so as not to restrict flow.

Thermal expansion and vibration of the pipelines must be compensated using vibration dampers and axial compensators to prevent additional loads.

The suction pipe must not contain air pockets, so it should slope slightly toward the pump.

The suction-side gate valve must be installed as close to the pump as possible; during operation it must be fully open and must not be used for flow regulation.

The discharge-side gate valve must be installed as close to the pump as possible to regulate flow during pump startup.

Additional pipeline connections and accessories

To monitor pump operation, install pressure gauges and thermometers on the pipeline. For automation — temperature and pressure sensors.

Each pump has threaded ports for connecting relief lines to the oil chamber. The oil chamber can be connected to a drain tank to allow oil removal in case of leakage. The connection must be made through a safety valve with a pressure rating equal to the pump’s maximum pressure.

Bypass installation

If the pump may operate for a long period with the discharge valve closed or with very low flow, a bypass line must be installed to return the medium to the suction line and prevent the pump from overheating.

The bypass line should connect the discharge pipe to the suction pipe.

On the discharge pipe, the bypass is connected between the pump discharge nozzle and the valve, with an overflow valve installed.

November 4, 2025

Sealed pumps for liquefied gases, chemically active liquids

Hermetic pumps are a special group of pumps designed for specific applications. This equipment is used for transferring particularly hazardous substances, such as liquefied ammonia, nitrogen, aggressive acids, and toxic materials.

Pumps of this type have no seals on rotating parts; their working chamber is completely hermetic, eliminating the possibility of leakage.

Technical specifications of the seal-less hermetic motor pump:

Capacity: Q up to 1200 m³/h.

Head: H up to 800 m.

Liquid temperature range: from -200 to 450°C.

Material: Metal: SS304/316/316L; Hastelloy C4, C276, etc.; Insulation: H, C, Super-C, etc.

Gasket: PTFE, metal spiral wound gasket, etc.

Flange standards: ANSI, ASME, HG, DIN, JIS, GB, SH.

Standard explosion-proof terminal box: Exd IIC T1-4, Exd IIB T1-4.

High-efficiency design with anti-cavitation characteristics.

Automatic axial balancing.

Seal-less hermetic motor pumps are used in the oil, chemical, medical, textile, and nuclear power industries, as well as in defense, shipbuilding, municipal water supply and wastewater systems, high-pressure firefighting systems, and high-rise building water supply applications.