December 2025 — Prom-nasos.com.ua

December 8, 2025

Pump flow control diagram during decanting

Decanter centrifuges are used for separating mixtures, emulsions, and various products into solid and liquid fractions by means of centrifugal force.

These units are widely used in various industries — chemical, food, mining, pharmaceutical, etc. Accordingly, the range of processed liquids is very broad.

To achieve the highest efficiency of the decanter, it is important to feed the product at a constant, stable flow rate, because if the volume of liquid supplied to the decanter fluctuates, the output products will have varying properties (the moisture content of the solid phase and the clarity/purity of the liquid fraction will constantly change).

The diagram below shows an example of maintaining a constant, stable flow rate using a flow meter (specifically, a rotameter with a milliamp signal).

This simplified diagram illustrates the principle of maintaining a constant supply of soybean oil to the decanter.

The product is fed to the decanter by means of a cantilever stainless steel pump . A rotameter with a 4–20 mA signal is installed on the supply pipeline; the signal transmitted by the rotameter to the control unit allows the pump speed to be adjusted in order to maintain a constant flow rate, thereby ensuring the highest quality of the output products.

December 5, 2025

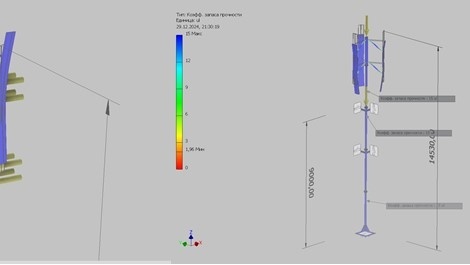

Masts for wind turbines

The installation of a wind turbine requires a mast (tower) on which it will be mounted. The height and design of the mast are calculated individually for each case.

The designs of vertical supports can vary significantly.

Guyed mast

This type of support is used for horizontal-axis wind turbines with a capacity of up to 10 kW.

Advantages:

low cost due to the use of pipes and profiles with a smaller cross-section;

possibility of installation without using a crane.

Disadvantages:

occupies a large area, since the guy wires must be anchored around the mast at a specific angle;

lower reliability compared to other types of supports;

requires maintenance.

Segmented mast

The support for a wind turbine consists of several segments (pipes of different diameters). The segments are connected to each other with flanges.

This type of structure is used for installing wind turbines across a wide power range. The mast height can reach 36–40 m.

Advantages:

high structural reliability;

simple and fast installation;

does not require maintenance.

Disadvantages:

the need to use a crane to install the wind turbine;

relatively high cost, as thick-walled pipes or profiles are used.

Monolithic conical mast

The vertical support is manufactured by welding steel strips into a hexagonal or octagonal shape.

The support is a solid conical structure with two flanges: a base flange for mounting to the foundation and a flange for mounting the wind turbine. The height of the support is limited to 12 m.

Advantages:

high structural reliability;

fastest installation;

does not require maintenance.

Disadvantages:

the need to use a crane to install the wind turbine, as well as transportation difficulties, since the support is non-dismantlable;

relatively high cost due to the use of thick-walled pipes or profiles.

Lattice mast

This is a mast manufactured using standard structural steel sections (angle steel, square or rectangular tube, round tube, etc.).

The mast height can range from 12 to 36 m.

Advantages:

high structural reliability;

does not require maintenance.

Disadvantages:

the need for welding work;

complexity of manufacturing.

Each structure requires an individual approach and is calculated for strength, rigidity, and stability.

When calculating the support, the main input data are the mass of the wind turbine, the mast height, and the wind pressure in the region where the wind turbine will be installed.

December 3, 2025

New series of impeller pumps from Italian manufacturer LIVERANI

LIVERANI impeller pumps are low-speed rotary pumps made of stainless steel with a flexible impeller. They are especially suitable for pumping delicate, fragile, and viscous liquids, as well as liquids containing solid particles in suspension.

LIVERANI pumps are widely used in the ECOLOGICAL sector (wine, must, grape must and destemmed grapes), in the FOOD INDUSTRY (beer, fruit pulp and juice, honey, liquid sugar, syrups, glucose, milk, melted butter, yogurt, liquid eggs, oil, tomato pulp and juice, brine, etc.), in the CHEMICAL INDUSTRY (starch, water-based adhesives, emulsions, glycerin, wax, detergents, rubber latex, photographic processing liquids, polyelectrolytes, paints, inks, industrial effluents, etc.), as well as in COSMETIC and PHARMACEUTICAL production (liquid soap, cleaning lotions, creams, shampoos, etc.).

Simple installation principle, a wide choice of materials and pump unit configurations

The quality systems applied throughout the entire production process allow us to offer a wide, versatile, and customized product range.

Each pump series can be manufactured with different types of impellers, mechanical seals, couplings, and in various configurations, namely:

pump with open shaft;

coaxial motorized pump (with an electric motor or an orbital hydraulic motor);

with gearbox;

with pulley (on a trolley or base);

with a mechanical speed variator or with a frequency converter.

December 1, 2025

Reasons for end seal and gland seal leakage

A mechanical seal or a reinforced lip seal (packing), according to the manufacturer’s instructions, does not require maintenance during operation. Undoubtedly, this is an exceptional advantage for anyone using a pump with such a sealing element. But there is one BUT!

The operating instructions for the product contain clear guidelines under which conditions the hydraulic part will maintain its tightness:

absence of “dry running,” i.e., operation of the pump without liquid present in the flow path. “Dry” operation is accompanied by rapid heating of the friction pairs and melting of the rubber bellows or rubber ring;

bearing wear leads to increased vibrations and impact loads on the seal’s friction pairs, resulting in leakage and possible subsequent flooding of the electric motor;

pumping liquids that contain abrasives or inclusions that may damage the seal;

ignoring the need to flush the pump after completion of operation. When pumping liquids prone to crystallization or sticking, the pump should be flushed to prevent the friction pairs from sticking together or the edge of the rubber packing lip from adhering to the shaft.

In the photos below, you can observe the consequences of packing leakage. When pumping milk, the containers were emptied “to zero,” followed by dry running. Pump flushing was also not performed.

As can be seen in the photos, the pump was operated for a long time after the packing began to leak. This led to the need to rewind the motor, replace the bearings, and replace the packing.

4 posts