About inches and millimeters

Undoubtedly, everyone knows that since the beginning of its existence, humanity has constantly used various systems for measuring distance (length), time, weight, and other quantities.

Different cultures and peoples used different measurement methods. These included feet, yards, miles (nautical and land miles, which, by the way, differ in length), cubits, millimeters, phalanges, inches, and so on.

In the context of our specialization — pumps, mechanical seals, and shut-off and control valves — let us clarify some specific aspects related to the use of length measurement units.

Today, the most widespread measurement systems are the metric system (or the International System of Units, SI, based on the meter and, accordingly, the millimeter as part of the meter) and the English system of measures (Common System), which is based on the inch.

The English system of measures is still widely used in the USA, Canada, Japan, and, of course, in the homeland of the inch — Great Britain. The metric system is used in Europe and most countries around the world, including Ukraine.

With the development of science, technology, and trade, the need arose to “link” inches to millimeters.

In 1930, the British Standards Institution adopted the inch value as 1 inch = 25.4 mm.

The international designation for the inch is in. In practice, it is often denoted by a double quote symbol — “””.

It would seem that the issue has finally been resolved. Although 25.4 is not a very convenient number for converting inches to millimeters or vice versa, with a calculator at hand even a primary school student can handle it.

But there is one BUT!

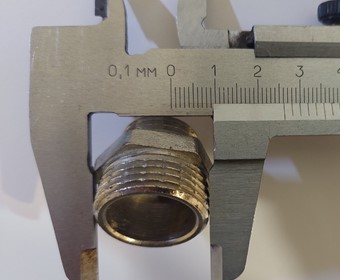

If you suddenly need to repair plumbing in your apartment and purchase a pipe fitting of, for example, 3/4" in a plumbing store, then measure its outer diameter, you will be surprised to find that it is approximately 26 mm (see photo below).

3/4’’ nipple

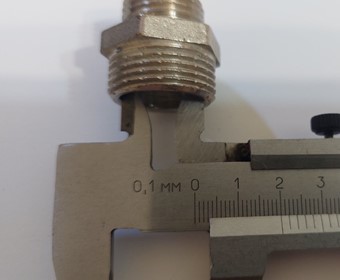

Logically, if 1’’ = 25.4 mm, then 25.4 × 3/4 (0.75) = 19.05 mm. So where did 26 mm come from? Did the store clerk make a mistake? In fact, there is no mistake at all. Wherever you buy a fitting of this size, its outer diameter will be about 26 mm. Likewise, a plug or nipple of size 1’’ will have an outer diameter of about 33 mm (although logically it should be 25.4 mm).

To understand this discrepancy, it is worth going back to the historical period when metal pipe production was just beginning. Since the inventor of the industrial method of manufacturing pipes from sheet metal was the English engineer James Russell, English units — inches — were used for pipe dimensions. In addition (and this is the most important point!), inches were used to measure the internal diameter of the pipe, not the external one.

This is very convenient for calculating pipeline capacity, that is, for hydraulic calculations. The sheet thickness could vary slightly, and therefore the external diameter varied, while the internal flow diameter always had a constant value expressed in inches — 1/2’’, 3/4’’, 1’’, and so on.

If you measure the internal diameter of the same fitting, you will see that it is about 20 mm (depending on the manufacturer, this dimension may vary from 19 to 21 mm). This size corresponds exactly to 3/4’’.

Since pipes had to be connected, pipe threads (specifically, English inch threads) were cut on the pipe ends. Historically, it happened that this thread began to be called “inch” thread and was designated by the size of the internal pipe bore.

Accordingly, it is clear that a certain wall thickness is required to cut a thread, because it is impossible to cut a thread of the actual size 3/4’’ (that is, 19.05 mm) on a pipe that has the same internal diameter. In our case, for this size the wall thickness is 3.5 mm. Thus: 19.05 + 3.5 + 3.5 = 26.05 mm.

That is why if you buy a 3/4’’ fitting in a plumbing store, its outer diameter will be about 26 mm; for 1/2’’ — about 21 mm; and for 1’’ — about 33 mm.

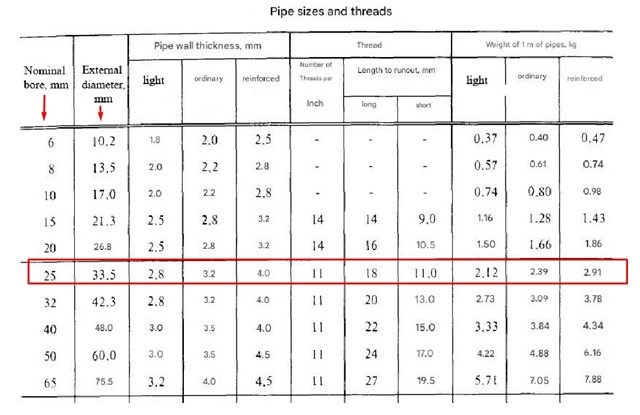

The table below shows other commonly used pipeline diameters.

As you can see, the first column on the left shows the so-called nominal pipeline diameter (that is, the conditional internal diameter of the pipe).

It is called conditional because the pipe may have different wall thicknesses, and accordingly the cross-sectional area may differ slightly.

If you divide this value by 1 inch (25.4 mm), you will obtain exactly those English inches that are traditionally used to mark plumbing fittings.

That is: 20 / 25.4 = 0.78 (3/4 inch), 25 / 25.4 = 0.98 (1 inch), 32 / 25.4 = 1.26 (1.25 inches or 1 ¼ inches).

The column to the right shows the actual outer diameter of the pipe in millimeters.

This specific feature of pipe inches and their actual discrepancy with millimeters should be taken into account when selecting pumping equipment and connecting elements for installation and piping.