Advantages and disadvantages of wet rotor pumps

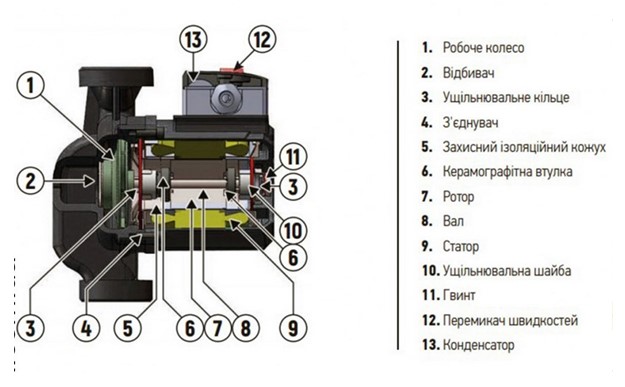

Pumps with a "wet rotor" have received their name due to the design feature – the pump rotor is supported by sliding bearings and is fully immersed in water.

The main advantage of this design is its noiseless operation. Since the rotor rotates on sliding bearings and lacks a cooling fan, the pump operates very quietly. Sometimes, the rotor's rotation can only be detected using a magnetic indicator.

Another advantage of this design is the absence of seals. It is a practically hermetic pump with only a vent plug at the end.

Moreover, most pumps with a "wet rotor" are equipped with a rotor speed switch, allowing optimal adjustment of the pump to your heating system even with minor calculation errors.

Undoubtedly, in private heating systems and in thermal nodes of multi-apartment buildings, where noise level is a critical factor, these pumps are virtually irreplaceable.

However, in industrial heating systems, boiler rooms, wood drying plants, and circulation cooling systems in the food industry, this design reveals its "downsides".

Since the gap between the rotor and stator is very small (0.5–2 mm depending on the model), the water cleanliness requirements are very high. Inclusions like scale, dirt, gasket remnants, or electrode fragments from pipe repairs or valve replacements can lead to pump failure.

This type of pump has low maintainability. Typically, service centers do not perform separate repairs of the rotor or stator or replace ceramic bearings. Instead, they offer complete replacement of the pump assembly, which costs about 80% of the pump's total price.

Another significant drawback, especially for industrial pumps, is the price. Many global leaders in pump equipment, such as Wilo, Grundfos, and DAB, have discontinued models with mechanical speed switching and now offer similar models with frequency control, which can be more than twice as expensive as the "old" models.

An alternative solution for replacing discontinued European-made pumps could be single-speed "wet rotor" pumps by EDWIN or using inline pumps with a "dry rotor" featuring a standard asynchronous motor.