Alpha-amylase and glucoamylase

Alpha-amylase and glucoamylase are enzymes used in the food, alcohol, biotechnology, starch-processing and other industries.

The use of enzymes in alcohol production is a key stage, as they increase reaction speed and provide a higher alcohol yield, which in turn makes the production process more efficient. Enzymes break down complex carbohydrates into simple sugars, which then undergo alcoholic fermentation with the participation of yeast.

The activity of enzymes is influenced by factors such as temperature, fermentation time and pH level. Maintaining these conditions ensures optimal starch breakdown and the decomposition of other complex compounds.

Alpha-amylase breaks down starch into shorter dextrin chains.

Optimal operating temperature – 85–95˚C. Optimal pH level – 5.8–6.2.

Glucoamylase converts dextrins into glucose, which is then fermented by alcohol yeast into ethanol.

Optimal operating temperature – 56–60˚C. Optimal pH level – 4.0–4.8.

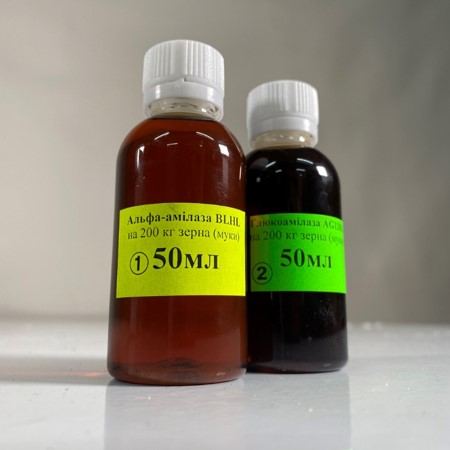

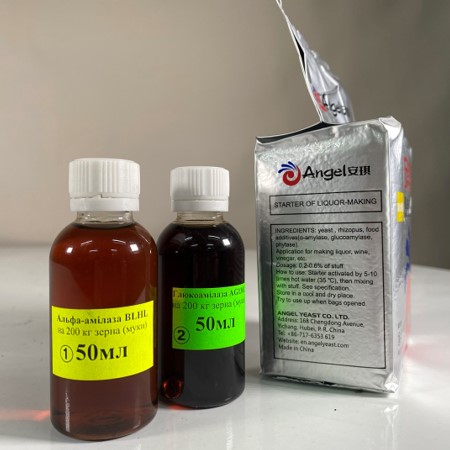

A set of enzyme preparations is available for sale, which includes 50 ml of alpha-amylase and 50 ml of glucoamylase.

This is the optimal enzyme dosage for producing distillates at home, calculated for 200 kg of grain (flour).

In combination with enzymes, yeast must be used for the production of alcoholic beverages. Cold fermentation alcohol yeast Kodzi Angel Leaven has proven to be highly effective.