Diapump DP series diaphragm pumps in filtration systems

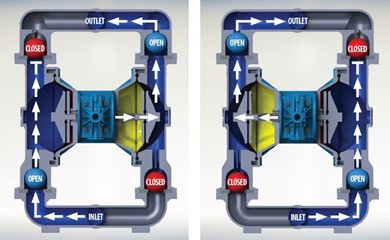

DP series diaphragm pumps from the Turkish manufacturer Diapump are pumps driven by compressed air. The compressed air enters the air distribution block, which alternately directs pressure into the air chambers, causing the diaphragm to perform reciprocating movements, changing the volume of the working (product) chamber and enabling the pumping process.

These pumps, made of plastic materials – PP, PVDF – can handle quite aggressive liquids such as sulfuric, nitric, hydrochloric acids, acid mixtures, galvanic solutions, etc. Additionally, the pump design allows for pumping liquids with a certain content of solid particles depending on the pump model.

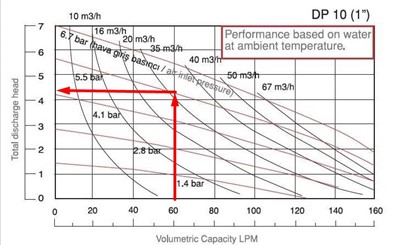

The working product pressure of the pump is considered to be one unit lower than the air pressure supplied. The maximum air pressure is 7 bar, so the product can be pumped at about 6 bar. However, the technically correct approach is to refer to the pump’s performance chart provided in the catalog for each model.

On the chart, the red lines represent air pressure, while the black curves represent air consumption. At the intersection of these lines, one can determine the resulting product pressure and flow rate depending on the inlet air pressure and consumption.

It’s no surprise that these pump features encourage engineers and technologists to use them for filtration in various technological processes.

However, when using a diaphragm pump for filtration, one must carefully calculate the pressure and take into account the pump’s operating principle.

First – the diaphragm pump produces a pulsating flow, and without special dampers, the filter will be exposed to minor hydraulic shocks with each diaphragm movement, which can significantly shorten the filter’s service life.

Second – as the filter becomes clogged, the backpressure in the product supply line increases, which may lead to the complete stop of the pump.

Conclusion – the use of diaphragm pumps in filtration systems is possible and effective, provided proper selection and calculation of the equipment, and when other pump types are difficult or impossible to use. Otherwise, preference should be given to centrifugal chemical pumps, magnetic drive pumps, or stainless steel centrifugal pumps.