Features of operation of centrifugal pumps when pumping viscous products

In general, for high-viscosity products, pump types such as impeller, lobe, gear, and diaphragm are commonly used — these are primarily positive displacement pumps.

For a number of products such as oil, transformer oil, a mixture of water and flour in a 1:4 ratio, beer wort, mash, and similar liquids, a centrifugal pump with an open or wide impeller can be successfully used.

An important aspect when using such a pump with the above-mentioned products is the need to rinse the pump chamber after the pumping process is complete.

This type of pump is equipped with a mechanical seal, which generally does not require maintenance during operation. However, if the pumped product is prone to crystallization, sticking, or clumping, this may cause damage to the seal.

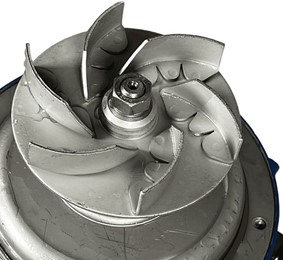

The photo below shows damage to the rubber bellows of the mechanical seal.

This occurred due to a failure to rinse the pump chamber in time. As a result, the friction surfaces were "glued" together by a starchy mixture, and when the pump was restarted, the rubber bellows tore.

As a result, the product began to leak from the working chamber into the space between the pump support and the electric motor.

In this case, the operator noticed the leak in time, and the mechanical seal was replaced. Otherwise, prolonged leakage could have caused damage to the electric motor, leading to significantly higher repair costs and delays in the technological process.

Our company not only sells pumping equipment and spare parts but also provides qualified selection and maintenance recommendations.