Operation of a gear pump

November 3, 2025

Gear pumps are positive displacement pumps that offer a number of significant advantages:

- they can pump high-viscosity products;

- they have the ability for “dry priming,” meaning they do not require pre-filling of the working chamber;

- the pumping process is smooth, with a stable laminar flow;

- the possibility of reverse operation;

- easy and precise flow regulation using frequency converters or mechanical gearboxes and variators.

Despite these excellent features, there are of course certain precautions that must be taken into account when operating a gear pump:

- The liquids being pumped must have lubricating properties (fats, glycerin, oil, motor lubricant, etc.). A gear pump must not be used to pump, for example, water, gasoline, solvent, or liquids containing solid particles. This can lead to the gears jamming and the motor windings burning out.

- The liquid should not contain hard abrasive or chemically active substances that can damage the working components — in particular the gears and the pump chamber. The design of a gear pump is based on minimal but sufficient clearances between the gears and the mating parts, which ensures high hydraulic efficiency and the advantages mentioned above;

- The pipeline or the pump itself must be equipped with a safety valve or bypass to prevent damage in case the valve on the discharge line is accidentally closed.

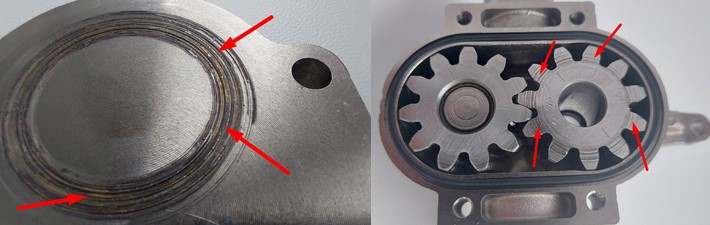

The photos below show a typical example of gear pump operation in which sugar syrup containing undissolved sugar crystals was pumped.

The photos clearly show wear on the cover, the end face of the gear, and the gear teeth caused by the mechanical impact of solid particles.

Conclusion — before operation, read the user manual, remember the important points described there, and follow the instructions — this will significantly extend the service life of your pump.