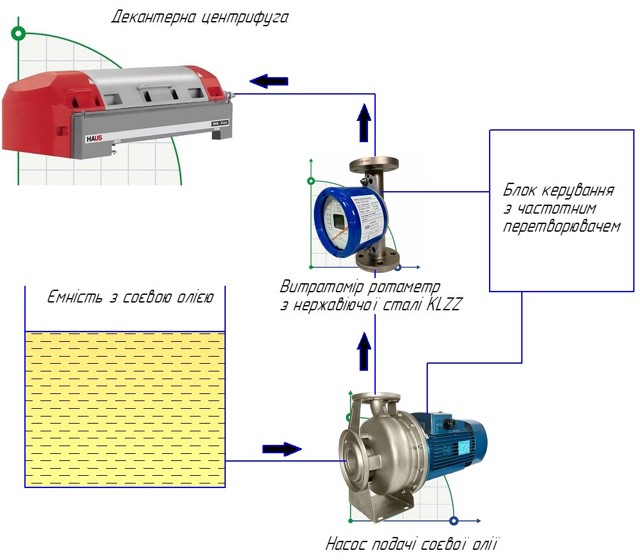

Pump flow control diagram during decanting

Decanter centrifuges are used for separating mixtures, emulsions, and various products into solid and liquid fractions by means of centrifugal force.

These units are widely used in various industries — chemical, food, mining, pharmaceutical, etc. Accordingly, the range of processed liquids is very broad.

To achieve the highest efficiency of the decanter, it is important to feed the product at a constant, stable flow rate, because if the volume of liquid supplied to the decanter fluctuates, the output products will have varying properties (the moisture content of the solid phase and the clarity/purity of the liquid fraction will constantly change).

The diagram below shows an example of maintaining a constant, stable flow rate using a flow meter (specifically, a rotameter with a milliamp signal).

This simplified diagram illustrates the principle of maintaining a constant supply of soybean oil to the decanter.

The product is fed to the decanter by means of a cantilever stainless steel pump. A rotameter with a 4–20 mA signal is installed on the supply pipeline; the signal transmitted by the rotameter to the control unit allows the pump speed to be adjusted in order to maintain a constant flow rate, thereby ensuring the highest quality of the output products.