Pumping equipment for washing particulate filters

Particulate filters are one of the main components of a vehicle’s exhaust system. This device ensures the purification of exhaust gases from an internal combustion engine from solid particulate matter, known as soot, which forms during fuel combustion.

Modern automotive engines are equipped with automatic systems for filter regeneration, which operate without driver intervention. However, over time, this cleaning becomes insufficient, and the filter must be removed for cleaning at specialized facilities.

There are two main methods of cleaning particulate filters – chemical and hydrodynamic. The chemical method requires the use of special reagents and appropriate equipment.

In contrast, the hydrodynamic method is more cost-effective and environmentally friendly. It allows restoration of up to 98% of the filter’s capacity.

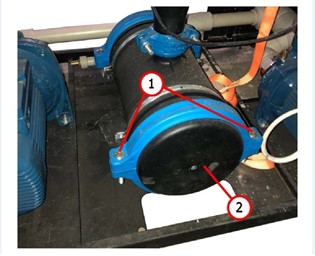

The main component of the hydrodynamic cleaning system is a centrifugal pump. Depending on the filter type, pumps with flow rates from 50 to 150 l/min and pressure of 4–7 bar are used.

The washing system can be of circulating or flow-through type. In circulating systems (where dirty water is filtered and reused), it is recommended to use single- or two-stage pumps with a pressure of 4–5 bar.

These pumps have an impeller wide enough to prevent clogging by soot and dirt particles.

In flow-through systems, vertical multistage high-pressure pumps (5–7 bar) can be used. The washing water does not return to the pump but is drained into the sewage, eliminating the risk of contamination.

Our specialists are always ready to assist you in the selection of pumping equipment for particulate filter cleaning stations.