Selection of pipe diameters to be connected to the pump

The main parameters of almost any pump are undoubtedly the flow rate (in cubic meters per hour, liters per minute, gallons per minute, etc.) and the pressure it generates (or vacuum, if it's a vacuum pump).

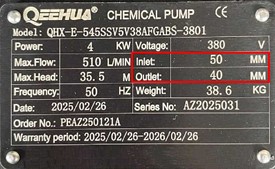

Of course, the manufacturer provides the pump’s technical specifications and guarantees that the pump can deliver the stated performance. These parameters are listed in catalogs, technical brochures, and also marked on the nameplate of the specific pump.

In addition to hydraulic data (maximum flow rate, maximum pressure or nominal values), the nameplate also includes the electric motor power and its characteristics.

However, the connection diameters, i.e., the inlet and outlet sizes to which the pump is connected in the system (marked “Inlet” and “Outlet” in English), are often overlooked.

At first glance, it seems simple – connect pipes that match the pump’s inlet and outlet diameters. But this seemingly logical assumption is actually incorrect and may lead to various issues during the operation of irrigation, circulation, or water supply systems.

It is essential to understand that the diameters of pipes connected to the pump must be determined through hydraulic calculation. This is the only correct way to select pipeline diameters. When replacing an old pump, if the new one has equal or better parameters, it usually works fine. But for a pump in a new system, hydraulic calculations must be done.

One must also remember that a pump is a dynamic machine, and the fact that the discharge port is, for example, DN50 does not mean the discharge pipe must be DN50 as well.

It’s also important to note that the parameters provided by the manufacturer in the documentation are based on specific test conditions. For example, for centrifugal overhung pumps, the nameplate data are based on the following:

- water temperature of 20˚C;

- suction depth of 1.5 m;

- liquid density of 1000 kg/m³.

In real-world conditions, these parameters often differ. Suction pipe diameter is especially important for centrifugal pumps. To avoid air suction, cavitation, and performance loss, the suction pipe must always be larger than the pump’s suction port.

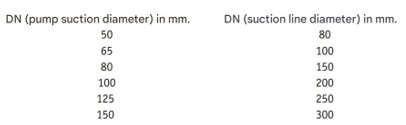

An example of pump and suction pipe diameter ratios as given in the catalog of a European manufacturer:

As shown in the table, the suction line diameter should be larger to ensure proper fluid flow into the pump’s working chamber. This is especially important when water is drawn from a depth of 4 meters or more. As suction depth increases, the pump’s flow-pressure characteristics change (i.e., reduced flow and pressure).

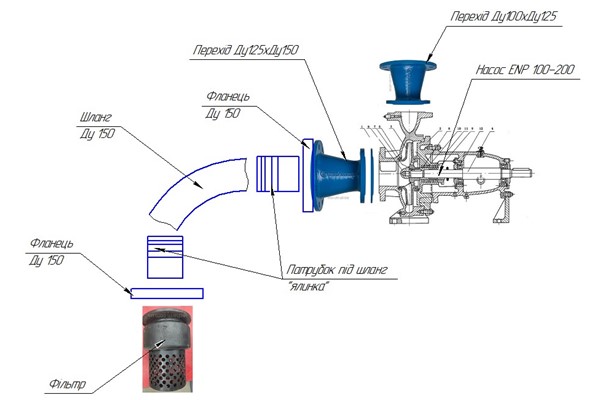

The image below shows a typical setup of a drip irrigation pump that draws water from a river, below the pump installation level.

The height difference between the water surface and the pump axis is small – only 1.5–2 m – but the suction pipe length is about 5 m. Therefore, a pump with a DN125 suction port should be connected with a larger pipe – at least DN150.