May 2021 — Prom-nasos.com.ua

May 28, 2021

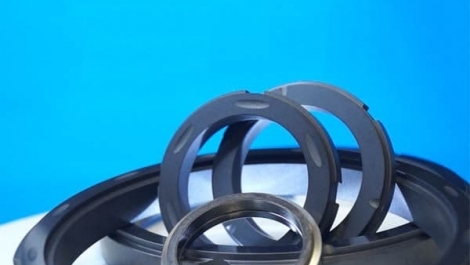

Repair of mechanical seals

May 25, 2021

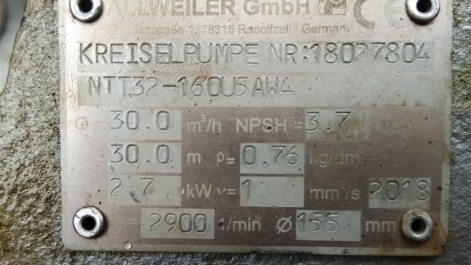

ALLWEILER NTT 32-160 U5 AW4 Pump Repair

ALLWEILER pumps are above all reliability and quality!

But no matter how correct the mechanism is, there are parts that need to be replaced or restored over time. Usually, rolling bearings, cuffs, and mechanical seals are replaced. Replacement of bearings is mandatory when a certain service life of the watch is running, regardless of their condition. The manufacturer describes the routine maintenance for service and warranty service. If the pumps operate in high temperature conditions, like hot oil pumps and with increased loads, then the service life of the bearings is reduced, so as not to cause their mechanical seal failure and workings on the pump shaft and housing.

EBARA mechanical seal for pumps - type of seal and pump brand.

Wear and tear of friction pairs if EBARA pumps are not protected against dry running

What if you proceed with a leaking pump mechanical seal:

product loss

liquid penetration into the electric motor

bearing failure

What to check when replacing the EBARA pump seal - the bearings.

Runout of the pump-motor shaft will damage the seal.

An example of the use of mechanical seals of the mixer shaft, agitator when mixing and preparing milk in the production of cheese. What cheeses are produced: Altai, mountain, Carpathian, Kuban, Soviet, Swiss, Biysk cheeses. It is known that in the production of most of these types of cheese, the temperature of the second heating and mixing with a mixer or agitator , is used , which is in the range from +47°C to +58 °C.

The process of mixing the product with the whey at different stages of maturation is very important for obtaining cheese, milk, whey as a product of high quality and sterility of the process. The process can be carried out both under heating and under vacuum or overpressure.

The main reason for the failure of the mechanical seal is the wear of the friction pairs or the destruction of the friction surfaces of the seal due to the runout of the shaft or working in "dry" conditions.

Replacement of the mechanical seal for the agitator-selection and consultation of the manager

4 posts