July 2021 — Prom-nasos.com.ua

July 16, 2021

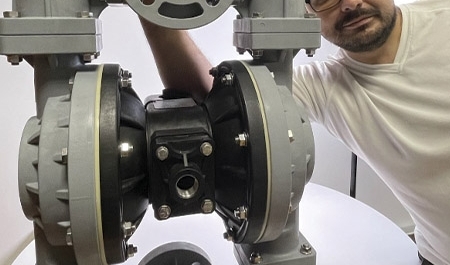

Pump for tug, daily drain

Pump for seawater with mechanical impurities and oil residues for daily drying. Our offer focuses on quality, durability and ease of use. There is a compressed air in compressor on tugboats and other water transport, that can be used to supply air to diaphragm pneumatic pumps, daily dehumidification pumps.

Ease of use and reliability! Long service life! Reliability !!!

The working position of the elements of the set of the hose-drum sprinkler machine provides:

the installation of a tractor-towed chassis with a hose wound on a drum at the hydrant of the pressure pipeline, which is connected to the pump

the unwinding the hose by dragging it with a tractor and laying it on the irrigation site in the sprinkling zone.

the installation of a platform trolley with a sprinkler at the end of the moistened irrigation zone.

the connecting the sprinkler to the hose and connecting the hose to the hydrant of the irrigation system.

the supply of irrigation water to the water supply hose and the inclusion of the sprinkler in operation (watering).

as watering proceeds, the hose is automatically wound at a certain speed on a drum driven by a turbine hydraulic drive (under the pressure of water coming from a pump to a hydraulic turbine or by means of a separate winding mechanism driven by a tractor.

under the force transmitted to the hose during its winding, the trolley with the sprinkler moves in the direction of the hydrant, thanks to which a strip of agricultural land is watered with a width of 30 to 90 meters and a length of up to 300 to 600 meters or more, depending on the model and size of the hose-drum set of the sprinkler machine.

Judging by the technology of work on the irrigation site, the hose-drum sprinkler device, the hose-drum device of rain irrigation to varying degrees refers to sprinkler installations and sprinkler machines. Due to the lack of its own propulsion for moving from one irrigation site to another and the need to use a self-propelled mechanism separate from the device when installing the sprinkler in the initial working position, the sprinkler (rain irrigation) under consideration refers to sprinkler installations. And on the basis of the presence of its own means for moving the sprinkler on the irrigation site during the irrigation process, this sprinkler can be attributed to sprinkler machines.

To date, a significant number of various domestic and imported designs and standard sizes of hose-drum sprinklers have been developed, some of which are discussed below.

This circumstance determines the possibility of using synonymous use of terms in the subsequent presentation: "hose sprinkler", "hose drum sprinkler", "hose drum unit" and (or)"hose drum sprinkler machine".

Diaphragm pump for detergents, gel, liquid soap, the ability to pump viscous products with active substances. Suitable for pumping viscous liquids and adhesives.

The pump is suitable for unloading and loading onto vehicles, as well as packing in euro cubic meters. Productivity of the DP series 15 to 20 m3 per hour. The ability to use in categorized rooms.

High-temperature cantilever pump ALLWEILER NTT - for pumping thermal oil, self-cooling. Pumps are used in particularly harsh conditions: asphalt production, mineral wool production, oil industry - processing of dark oil products, bitumen production, heating of bitumen tanks, paint and varnish industry, food industry, production of plastics, tires, rubber, roofing, etc. Accordingly, the mechanical seal must be as durable and reliable as possible.

BTS seals fully meet these criteria, using Viton rubber (fluoroelastomer), solid carbon, antimony-impregnated / SSic, silicone carbide.

Shaft seal U5A (item 433.02) - uncooled, maintenance free, unbalanced. In front of the mechanical seal there is a safety stuffing box with the next throttling zone. Even if the mechanical seal fails, these additional safety elements prevent fluid from leaking. It is guaranteed that any leakage heat escaping from the shaft seal is safely discharged through the LO leakage outlet and fully collected. Due to the special design of the integrated unit, the temperature is reduced to such an extent that proper functioning of the bearing and shaft seal is ensured.

Centrifugal pump FLOWSERVE WDX series - horizontal, multistage, with vane diffuser. WDX pumps are modular in design with identical stages. A variety of optimal characteristics and materials allow it to be used for a variety of purposes, such as boiler feed or reverse osmosis.

Modifications of these pumps imply the use of both stuffing box packing and mechanical seals .

General recommendations for the use of a mechanical seal in FLOWSERVE WDX pumps:

Mechanical seals do not require adjustment.

Slight initial leakage will stop when the packing has been burned in.

During the assembly operation, special attention should be paid to cleanliness.

Before pumping dirty liquids, it is recommended to run-in the mechanical seal with a clean liquid to protect the friction pairs.

Routine maintenance consists of checking the tightness. it necessary to detect any small leak.

Never run a mechanical seal dry, even for a short time!

5 posts