News Prom-nasos

August 30, 2024

Installation of a wind turbine

Choosing a wind turbine

The choice of wind turbine depends on your electricity needs. There are different types of wind turbines:

Vertical wind turbines : Suitable for private homes and capable of producing from several hundred watts to several kilowatts of electricity.

Horizontal wind turbines : Used for small commercial enterprises and can produce from a few kilowatts to several tens of kilowatts.

Preparation of Tools and Equipment

To install a wind turbine, you will need the following tools and materials:

Foundation bolts;

Crane or hoist ;

Electrical cables ;

Inverter (for converting alternating current to direct current);

Protective equipment (helmets, gloves, etc.).

Installation of the Foundation

The foundation is an important part of the wind turbine construction. It must be strong enough to support the weight of the generator and withstand strong winds.

Dig a foundation hole according to the dimensions and requirements of your wind turbine.

Install the rebar and pour concrete to create a strong foundation.

Fix the foundation bolts in the concrete until it hardens.

Installation of the Pillar

Once the foundation has hardened, the installation of the pole can begin.

Use a crane or hoist to lift the pole and place it on the foundation.

Fix the post with foundation bolts and check its verticality.

Installation of a wind turbine

The next step is to install the wind turbine itself on the pole.

Lift the wind generator with the crane and attach it to the top of the pole.

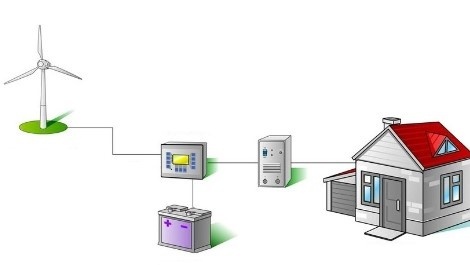

Connect the electrical cables from the generator to the inverter and the energy storage system (battery).

Connect and configure

After the generator is physically installed, it must be connected to the electrical system.

Connect the inverter to the generator and to your power grid.

Adjust the charge controller for optimal operation of batteries .

Check all connections and make sure they are secure.

Testing and Launch

After the installation is complete, test the system:

Check the operation of the wind generator at different wind speeds.

Ensure that electricity is generated and delivered to your grid or storage system.

Adjust settings for optimal performance.

Conclusion

Installing a wind turbine is a complex but important process that will allow you to harness renewable energy to power your home or business. If you follow all the steps correctly, you will be able to ensure stable and reliable operation of your system. If you encounter any difficulties, it is recommended that you contact a professional to install and configure your wind turbine.

August 29, 2024

Types of wind turbines

Wind turbines are an efficient way of harnessing wind energy to generate electricity. They can be used in both private households and commercial enterprises. Wind turbines are an increasingly popular source of renewable energy that harness the power of the wind to generate electricity, reducing dependence on traditional fossil fuels. There are two main types of wind turbines: horizontal and vertical .

Horizontal wind turbines (HAWT)

Horizontal wind turbines are the most common and most efficient. Their blades are perpendicular to the ground and the main shaft is parallel. They resemble classic windmills with long, thin blades. These generators work best at high wind speeds and are often used in large wind farms.

Advantages:

High efficiency under optimal conditions.

Well-developed technologies for large-scale production.

Highest power among available options.

Disadvantages:

High initial cost.

The need for a complex management system.

Vulnerability to strong winds and turbulence.

Vertical wind turbines (VAWT)

Vertical wind turbines have an axis of rotation that is perpendicular to the ground. Their blades are arranged around a shaft, allowing them to operate regardless of wind direction. This makes them ideal for urban environments and locations with variable winds.

Advantages:

Simplicity in installation and maintenance.

Efficient operation at low wind speeds.

Less impact on the environment and aesthetic appearance.

Disadvantages:

Lower efficiency compared to horizontal wind turbines.

Limited power making them less suitable for large projects.

Conclusion

The choice between horizontal and vertical wind turbines depends on the specifics of the terrain, climatic conditions and power requirements. For large wind farms with high wind speeds, horizontal wind turbines are the best option. At the same time, vertical wind turbines are ideal for urban environments and locations with variable wind conditions, where their versatility and simplicity are key advantages.

Pumping equipment with a high capacity, and therefore a large volume of water that can be moved per unit of time, makes up a much smaller percentage of the total number of pumps used in industry and agriculture.

These pumps are used by local water utilities, heat supply companies to supply drinking water or heat supply of villages, towns or even entire neighborhoods of large cities. In addition, these pumps can be used for water lowering , water storage for irrigation and irrigation in agriculture , pumping water from construction pits, etc.

As a rule, when the question arises of quick delivery of a pump whose power is greater 20-30 kW , to start production or solve an emergency situation, the supply department faces the problem of long delivery times and prices.

Our company is ready to offer high-capacity pumps in stock in Ukraine at the best prices.

In particular, these are compact (despite high power) pumps of the design in-line .

For example, there are such models available as IRG 200-315(I) , IRG 100-200 (I) , IRG 200-315 (I) A.

These pumps are very convenient to install, as the motor is placed vertically, and the pressure and suction nozzles are on the same line. The vertical placement of the motor also prevents the electric motor from flooding if the end seal is damaged.

Self-priming and normally aspirated pumps

Theory

The maximum theoretical depth from which any pump on planet Earth can raise a liquid is minus one physical atmosphere, in meters of the water column, it is approximately 10.3 m. That is, there is no pump that can draw a liquid from a greater depth (no centrifugal , not vacuum , or diaphragm or any other).

Another misconception is that a pump with a power of, for example, 11 kW can ‘pull’ liquid from a greater depth than a pump with a power of 0.55 kW. The power of the pump affects its capacity and pressure, and has no bearing on the depth from which it can draw fluid.

Practice

Normal suction pumps

In fact, the vast majority of pumping units are normally suction pumps. This includes the entire group of centrifugal pumps, which are dynamic pumps (with a spiral impeller, vortex, radial or other). These pumps cannot self-priming (pull liquid without being primed) because when they start up, without liquid in the working chamber, they are essentially pumping air, and since the density of air is much lower than that of any liquid, the suction force (vacuum) is not sufficient.

In order to start such a pump unit, it is necessary to first fill the working chamber of the pump with liquid (water, alcohol , ethylene glycol, milk etc.). In addition, if the liquid level is below the axis of the suction pipe, a non-return valve must be installed at the end of the pipe, so that after stopping the pump, the liquid remains in the working cavity and it is possible to start working again.

A group of pumps with a pre-priming chamber should be selected separately. Although they are conventionally called self-priming, in fact these pumps are also normally priming and also require the presence of liquid in the working chamber to start work. The only difference is that you only need to fill the pump once, since the presence of a pre-filling chamber allows you to keep a reserve of liquid sufficient to start the pump. Accordingly, this feature allows the use of such pumps without a non-return valve.

Self-priming pumps

In most cases, when people talk about a ‘self-priming’ pump, they mean a unit that can draw liquid without pre-filling, simply by throwing a hose or lowering a pipe into the liquid.

Displacement pumps have this property - piston, diaphragm , impeller , peristaltic , roller pumps etc. The principle of operation of these pumps is based on a change in the volume of the working chamber, as a result of which they can draw liquid without filling.

This feature is very useful when working with aggressive substances, such as acids, alkalis, mineral fertilisers and other liquids, when it is not possible to fill the working chamber.

This group includes the vast majority of pipette pumps (plunger, diaphragm, peristaltic). Simply lower the suction nozzle (hose) into the reagent and switch on the pump, and the process of filling the working chamber and further operation will begin automatically.

Irrigation is used to increase agricultural yields, especially for bulb crops such as onions.

Heated soil at the time of planting, regular watering of onions and the right choice of irrigation system , especially in hot and dry summer, supports the development of rape heads and increases total yield. Irrigation is the most advanced method of irrigation today.

Our regular customers used pumps driven by the tractor take-off shaft , but constant loading tractors for irrigation does not always justify itself. Therefore, it was decided to purchase a diesel pumping station for irrigation to irrigate 70 hectares of onions.

The diesel pumping station was delivered with the parameters of 180 m3 and a pressure of 89 meters maximum.

This high pressure and flow rate is provided by a 75 kW 3000 rpm diesel engine.

The diesel engine is equipped with a system for monitoring operating parameters and is equipped with a MEBAY controller:

Engine revolutions;

Oil pressure;

Coolant temperature;

Charge voltage of the battery;

Monitoring of operating hours, for timely replacement of oil and filters and maintenance.

Shipment of a diesel pumping station for irrigation

We are grateful for the cooperation of our customers! May it serve to increase the harvests and wealth of our agrarians and the entire team! We wish peace and good to everyone!

When deciding whether to connect the inverter to the grid or directly to the load, it is important to understand the functional differences, advantages and disadvantages of each configuration.

1. Connecting the inverter to the grid (grid-connected inverter)

Advantages:

Net metering: Excess electricity generated by your system can be sold back to the utility grid, often earning credits on your electricity bill.

Energy storage: The grid acts as a virtual battery, storing excess energy and providing it when your generation is low.

Effectiveness: generally there is no need for expensive battery storage systems. Reduced environmental impact: Efficiently uses renewable energy sources and helps reduce the overall carbon footprint.

Disadvantages:

Regulatory Compliance: Requires compliance with local utility codes, permits, and sometimes additional equipment, which can be expensive and complex.

Mains Dependency: If the grid goes down (such as during a power outage), a grid-connected inverter system will typically not provide power unless there is a backup battery.

Variable energy costs: Energy prices and policies can change, affecting the financial benefits of selling excess electricity.

2. Connecting the inverter directly to the load (autonomous inverter)

Advantages:

Network independence: ideal for remote locations where network connectivity is not possible or reliable.

Energy Security: Provides power even during power outages, making it suitable for critical applications that require uninterrupted power.

Autonomy: full control over the production and consumption of electricity without dependence on utility companies.

Cost savings in remote areas: avoids the potentially high costs of extending network infrastructure to remote locations.

Disadvantages:

Energy storage requirements: A battery is usually required to provide a stable power supply when generation is low, which can be expensive and require maintenance.

System complexity: Managing an autonomous system can be more complex due to the need for energy storage, backup generators, and ensuring that power supply matches demand.

Initial Investment: Higher initial costs due to the need for batteries and possibly additional equipment such as charge controllers.

Summary of differences:

Grid-tied inverter: connects to the grid, provides clean metering, reduces dependence on batteries, but is dependent on the grid for power continuity during outages.

Standalone inverter: connects directly to the load, requires a battery for continuous power operation, provides independence from the utility grid, but requires higher initial and maintenance costs.

Choosing the right option: Consider a grid-tied system if: You have reliable grid access, want to reduce your electricity bill with net metering, and prefer a simpler system without the need for battery storage.

Consider a standalone system if: You are in a remote area without reliable access to the power grid, you need energy independence and security, and you are willing to invest in and maintain a battery storage system.

BASIC RULES

Effective and trouble-free operation of a diaphragm pump , like any other type of equipment, must begin with installation in accordance with all the rules. This will make your life much easier. A solid foundation, correct pipeline geometry, sufficient diameter of pipes - at least one aspect was missed, and now vibrations, increased pressure and other negative factors begin their destructive activities. Maintenance of the diaphragm pump does not tolerate neglect of the instructions. It is necessary to tighten the housing nuts before commissioning - do this. Testing is provided with measuring the flow and pressure of the unit at certain parameters of air flow and pressure - carry it out.

A common cause of breakdown of a diaphragm pump or a decrease in its productivity lies in the incorrect use of the pneumatic pump, or neglect of the operational requirements stated in the pump passport. The pneumatic diaphragm pump is simple in design and works with thick and viscous liquids, including glue, acids or food. Can pump abrasive particles with a diameter of up to 10 mm. But if used incorrectly, advantages can turn into disadvantages.

Before starting to operate a diaphragm pump, it is of great importance to select the correct elements of air preparation, filters, moisture separators, pressure reducing valves, etc. Pressure filters include air filters (inlet, fine, inline, high pressure or stainless steel) and water filters. Air filtration using inlet filters removes coarse contaminants. Air filtration is at the level of 20 um, in the case of large filters - 50 um. Inlet filters are installed immediately after the compressor. It is worth remembering that frequent replacement of filter cartridges improves the quality of the compressed air at the outlet. In the case of thin filters, installation should be carried out at the compressed air intake points. Their task is to prepare the air under the specified conditions. Fine filters should always precede the inlet filter. Depending on the application, air filtration is 5 microns, 0.3 microns or even 0.01 microns. On the other hand, in-line filters are installed where there is no physical space for standard filters. They are very often used in front of pneumatic tools. The air filtration of such filters is 20-30 microns. Improper preparation of the air supplying the pump can lead to failure of the pump, or its main parts, such as rubber products and, in general, the pneumatic valve of the diaphragm pump.

Installation of an air operated diaphragm pump

Before the pump, air preparation ( reducer, filter-moisture separator, throttle ).

Pneumatic line of sufficient diameter.

Only horizontal placement of the pump.

Since diaphragm pumps are self-priming, it is important for them to ensure tight connections .

Before turning on, be sure to check that there are no foreign objects in the pump , that the seals have been broken and that the screws are tightly tightened .

The diaphragm pump can be installed both on the floor and on the ceiling, it is important that the pump is installed horizontally (standing on its feet), the fluid supply manifold is at the top of the pump (pay attention to the arrows that are drawn on the pump, they indicate the correct direction, the arrow should point upward as shown in the figure).

! VERY IMPORTANT ! Such an industrial pump should be located as close as possible to the place where the liquid is pumped and from where it is taken. This will ensure maximum performance. As you know, the longer the hoses and the more viscous the liquid, the greater the deviations in pump performance from those stated in the passport.

Starting the diaphragm pump

The valve balls must be moistened with hydraulic fluid before starting the pump. The pump must be dried from water if water is not allowed to enter the pumped liquid. Initially, there may be water in the diaphragm pump, since its functionality is checked by pumping water before shipping.

Basic rules for servicing a diaphragm pump

Many aspects of using a diaphragm pump are intuitive. But we want to focus on the key ones.

A superficial inspection of the pump should be done at least once a month to replace filters as necessary and check the integrity of the pump. If there is liquid under the pneumatic cap, this is a bad sign; most likely a crack has formed somewhere and this may soon lead to the final breakdown of the pump. In this case, you can immediately contact us to replace damaged parts, inspect, or, in extreme cases, purchase a similar pump.

Replacement of parts is carried out in a clean and dry room. Parts are replaced only with new, original ones.

Before disassembling the diaphragm pump (depending on the pumped liquid), the technician must wear gloves and goggles , in case of working with toxic substances.

Before disassembling the pump, you need to WASH it to get rid of toxic liquids as much as possible.

Before disassembling after washing the pump, it is necessary to DISCONNECT from the compressor, DISCONNECT the inlet and outlet pipes.

Then you can proceed directly to disassembling the diaphragm pump, if necessary.

! VERY IMPORTANT ! If the pump is rarely used, or you plan to postpone the operation of the equipment for some time, It is NECESSARY to flush the pump of the pumped substance to avoid sticking of the channels.

AIR CONNECTION DUCT HUMIDITY

The presence of water in the compressed air system can cause problems such as freezing of the water or icing of the discharge line, causing the pump to run unevenly or stop. These problems can be overcome by using a point-of-use dehumidifier in addition to the user's air drying equipment. Air drying equipment will remove water and eliminate problems such as freezing or icing.

The air pressure should not exceed 7 bar. The pump must be supplied with air at a pressure and flow rate to provide the desired performance.

AIR VALVE LUBRICATION

The pump should be flushed after each use to prevent damage if the pump is used to pump liquids containing suspended particles that will settle and harden over time while the pump is stationary. (Otherwise, product left in the pump between uses may dry out or settle. This may cause problems with the diaphragms and check valves when restarted.) The pump should be completely drained after each use, especially in freezing temperatures.

Inoxpa Hyginox SE series centrifugal pumps are compact, with hermetic connection and sanitary design. They are used in factories where sterile conditions are necessary when pumping non-abrasive liquids of low and medium viscosity (up to 200 Sp).

The body and impeller are made of AISI 316L cold-pressed stainless steel, which makes it suitable for use as the main process pump in:

dairy industry

brewing, winemaking

production of vegetable oil

production of drinks, juices

in other areas of the food industry

pharmaceuticals

cosmetic industry, etc.

The liquid is allowed at a temperature of 120°C (140°C SIP, max- 30 min).

Mechanical seals and others in contact with the product are made of EPDM.

The default is:

Single internal face seal EN 12756 l1k (according to FDA and EC 1935/2004).

Moving part - Graphite (C).

Immovable part - silicon carbide (SiC).

Sealing elements – EPDM.

Options:

Friction pairs - SiC/SiC.

Sealing elements – FPM.

In our case, the cause of failure of the end seal of the pump Inoxpa 1G110-4452025CE EN12756 L1K MECHANICAL SEAL SIC/SIC/EPDM 25 FDA CE 1935/2004 (analog AESSEAL-B012-ADY1-025) became the so-called "dry run".

The pump was running without fluid for some time, and the internal parts of the pump were subject to increased friction without sufficient lubrication. The resulting heat caused the seal to fail. Most dry run failures occur when the pump is restarted after maintenance without checking that the pump is completely filled with liquid.

Just a few seconds of dry running can cause the mechanical shaft seal to most likely be permanently damaged!

Inoxpa 1G110-4452025CE mechanical shaft seal required - contact BTS Engineering!

March 27, 2024

Borehole pumps 4SD

Borehole pumps are reliable devices that are used to lift water from deep wells of different diameters or reservoirs. Deep pumps have become a necessary component of modern water supply systems, providing reliable water supply both in everyday life and in industry. 4SD pumps can be used in both vertical and horizontal (surface) positions.

To raise water to the surface from a well, the pumps are installed vertically and lowered into the well on a water-lifting pipe (plastic or metal) and additionally secured with cables.

To pump water from reservoirs, the pump can be installed in a horizontal position on a special stand with a cooling casing.

For efficient and trouble-free operation of pumps, they should be used with control panels. The pump control panel not only provides automation of water supply, but also provides protection against dry running, overload, and also protects against phase loss, phase imbalance, and overvoltage.

Pumps of a well-known manufacturer Allweiler ALLHEAT are intended for the circulation of heat carriers such as grease or hot water at high temperatures (water up to 207°C or thermal oil up to 350°C).

In particular, the NTWH/CTWH series pumps are single-stage horizontal centrifugal pumps with optimized bearing support, with spiral casing. Thanks to the long cooling section, no additional cooling is required. The massive slide bearing is pumped fluid lubricated, available in SSiC/SSiC or carbon/steel. The large area of the specially designed mechanical seal chamber prevents dry running. Before sealing the shaft, a safety gland and the following throttle section are installed.

The following shaft seals are used in these pumps:

Uncooled, balanced or unbalanced, according to DIN 24 960.

Mechanical seal

Product code U2.11A - balanced,

Product code U3.3A - unbalanced (Burgmann 951534 037797000 AQ1VGG).

Materials: moving ring - graphite A, counter ring - SiC, silicon carbide Q, spring - CrNiMo steel, sealing rings - fluorine rubber (FPM) V.