News Prom-nasos

March 21, 2025

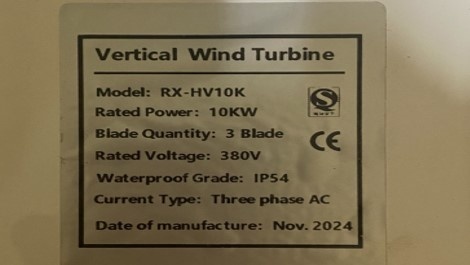

Vertical wind turbine 10 kW

In the modern world, wind turbines are rapidly gaining popularity in various fields. They are used both for personal needs and for selling electricity for passive income.

We are installing a vertical wind turbine with a 10 kW 380 V H-Type series. This wind turbine can withstand wind gusts of up to 65 m/s. The operating temperature range is from -40 °C to +80 °C. The diameter of the wind wheel is 3.9 m. It consists of three blades made of aluminum alloy and is protected from overload by an electromagnet, which serves to brake the wind turbine. The magnet is made of a rare earth neodymium iron-boron material, NdFeB, which is also called the "king of magnets".

March 20, 2025

Pump with hydraulic drive HYDRO-2

Hydraulic motor pumps from the Italian company are reliable, easy to use, and simple to maintain. Due to the use of hydraulic drive, such a pump can easily fill tanks, barrels, etc. The main areas of application are: irrigation, fire fighting, creating water troughs, and so on. The maximum performance of this pump is 20 m³/h, and the lift height reaches 27 meters of water column.

You can order or learn more about this pump by following this link .

February 24, 2025

ML series paddle mixers

Paddle mixer series ML is designed for mixing liquids and solutions without the presence of solid insoluble inclusions larger than 5 mm, with dynamic viscosity not exceeding 400-1000 cP, and temperature not higher than 90°C.

All parts of the mixer that come into contact with the product are made of stainless steel AISI 304 (equivalent to 12Х18Н10Т).

Operating conditions:

ambient temperature not exceeding 40°C;

relative humidity not exceeding 80%.

The paddle mixer ML consists of the following main parts (see the diagram):

1 — electric motor, 2 — worm gear reducer, single-stage, 3 — support flange with shaft sealing, 4 — shaft, 5 — impeller.

The operating principle of the mixer is based on transmitting torque from the electric motor to the impeller through a single-stage worm gear reducer. The reducer reduces the speed of the mixer shaft to the required level, while increasing the torque.

The mixer is driven by a three-phase asynchronous electric motor (pos. 1). The worm gear reducer (pos. 2) is single-stage and housed in an aluminum casing. The ML mixer has a support flange with shaft sealing (pos. 3), designed for mounting the mixer on a tank or special stand. The shaft (pos. 4) is hollow and made of stainless steel. The impeller blades (pos. 5) are positioned at a 45° angle to the shaft axis.

When the impeller rotates, the axial force directs the product being mixed down along the shaft axis and partially in the radial direction, ensuring proper mixing and preventing sedimentation at the bottom of the tank.

For poorly soluble and more viscous products (viscosity 2000-5000 cP), it is advisable to use two-level mixers with two rows of impellers, offset at a 45° angle.

Applications of Paddle Mixers

The paddle mixer has a simple and reliable design and is widely used in the chemical industry. It is essential not only for mixing liquid reagents but also in cases where the mixing agent is gas or air, as well as for mixing liquids and gases. Besides chemical production, paddle mixers are used in:

the paint and coatings industry for the production of coloring compounds and colorants;

the oil industry for mixing petroleum products;

the pharmaceutical industry for creating various liquid medicines;

the construction industry for making building mortars and mixtures.

February 21, 2025

A brief overview of pumping equipment driven by a PTO from the Turkish manufacturer Ekler

The Turkish manufacturer Ekler presents a range of small and medium power pumps for drip and sprinkler irrigation, filling containers, creating water reserves for water supply, firefighting, and applying liquid mineral fertilizers.

These are cantilever pumps with a gearbox (multiplicator), which increases the rotational speed of the impeller.

The pump is mounted on the three-point hitch of the tractor, and the drive is transmitted via the power take-off shaft.

Also interesting might be models with hydraulic drive Hydro-2 and Hydro-3.

Due to their compactness, they can be mounted on the tractor or vehicle. They are most often used for unloading and loading tankers.

Another pump model that will be an indispensable helper for the housing and communal sector, repair teams performing repair and emergency work on pipeline break sections. For pumping dirty water or sewage, check out the MTZ-UK 50T pump.

This pump, unlike the models described above, has a pre-fill chamber, which eliminates the need to pre-fill the working chamber. It can suction liquid from a depth of 6-7 meters.

A separate group of pumps from Ekler is the PTO series pumps, designed for road transport.

Such pumps can be widely used in specialized automotive equipment working in construction, agriculture, where electric pumps cannot be used. When choosing a pump, attention should be paid to the direction of rotation of the power take-off shaft – left or right. The drive of the pump impeller is provided by a compact gear transmission.

Our website also features other brands that have a power take-off drive, such as Ferroni, ROVATTI, Veneroni .

You can always contact our specialists to choose the best option.

February 14, 2025

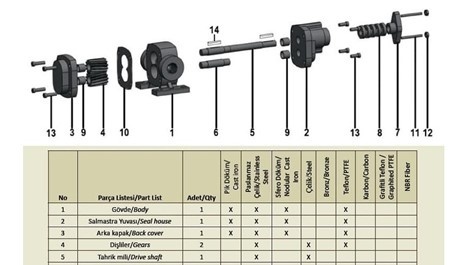

EMSE gear pumps with external gearing

Gear pumps are designed for pumping a wide range of liquids with high viscosity.

EMSE gear pumps of the EDP series (with external gearing) can pump fuel oil, caustic soda, oil, glue, mineral oil, gel, grease, chocolate, soap raw materials, glucose, quaternary esters, glycerin, rubber, wax, honey, molasses, oil and much more.

The advantage of external gear meshing is the simplicity of construction and repair.

The EMSE pumps of the EDP series are also equipped with helical gears, which significantly reduces operating noise and radial load on the shaft.

An important feature is the ability to use both gland packing made of various materials and mechanical seals.

Mechanical seal of the EDP pump

These pumps can be supplied without a motor - with a free shaft end - or as complete units ready for operation.

Choosing a gear pump for pumping a certain type of product is a rather complicated task for those who use or plan to use this type of pump for the first time.

The same pump unit can be equipped with motors of different power and speeds.

The material of the housing and gears can also vary depending on the customer's wishes: it can be cast iron, structural steel, stainless steel AISI 304, AISI 316, Teflon.

The operating temperature range is from -20 to +180 °C.

Rotation speed from 200 to 1500 rpm.

Our experts will help you choose the best option in terms of parameters and price! Don't hesitate to contact us!

January 24, 2025

Peristaltic pump B3-V 0103 90-260V Santoprene

At first glance, the peristaltic pump B3-V 0103 90-260V Santoprene has a simple structure, the main elements of which are a hose and rollers attached to a shaft, with the help of which liquid is pumped through the hose. Due to the fact that the rollers and shaft are not in contact with the liquid, it allows it to pump aggressive solutions. It is used for pumping: acid, liquid powders, coagulant, solutions, alkali, antiseptic and various chemicals. The capacity is manually adjustable from 10-100%. The main advantage of the pump is its reliability, compactness, and non-contact pumping, which makes it cost-effective to maintain.

December 13, 2024

Pumps for swimming pools

Swimming pool pumps are conventional centrifugal pumps. The only difference is that they usually have an integrated coarse filter (see Fig. 1), the so-called ‘hair filter’, in their housing.

In general, the prefix ‘pumps for water supply, heating, well or swimming pool’ is determined by the system or place where the pump will be used. Accordingly, the same pump can be used in different systems. That is, no one prohibits the use of a water supply pump in a pool circulation system, as long as it meets the required parameters.

Pumps used in swimming pool filtration and circulation systems must provide sufficient water supply, which depends on the volume of the pool. The pressure created by the pump is usually in the range of 1 to 2 atm. This pressure is quite sufficient both for circulation and to overcome the resistance of the filtering system (sand filters).

Since the water in the pool is disinfected, it contains a small concentration of sodium hypochlorite, so the material of the flow part should be made of plastic or stainless steel.

The absence of an integrated filter can be easily compensated for by using a conventional coarse filter in the suction line. When using pumps with an open impeller (see Fig. 2), a filter can be dispensed with, as this type of impeller does not clog, and impurities and dirt are further stopped by the sand filter and do not re-enter the pool.

Our specialists have successfully replaced a classic plastic pool pump with a centrifugal stainless steel pump.

Since the pump to be replaced had failed due to a motor winding burnout, a protection and control panel was also installed to control the new pump and the protection parameters were adjusted accordingly.

Pump that has failed

New pump

December 5, 2024

Problems when starting a self-priming pump and solutions

Self-priming pumps with a pre-filling chamber can operate without installing a check valve at the end of the pipe. These pumping units are convenient for unloading tanks with oil products, diesel fuel, petrol, oil and other liquids.

The ability to suck in liquid is ensured by the built-in check valve and the design of the pump casing, which stores a certain level of liquid to start the pump. However, for the first start, there still needs to be liquid in the working chamber, so you will have to fill it up the first time. For this purpose, a filler connection is provided on the casing (see Fig. 1 item 4, Fig. 2).

The table below shows typical faults that may occur during operation of a centrifugal self-priming pump and how to resolve them.

November 29, 2024

Energy-saving pumps with frequency converter

Pumps are indispensable devices in many industries, from heating systems to industrial equipment. Choosing the right pump can significantly improve system efficiency and reduce energy costs. Let's take a look at the features and benefits of these pumps.

Energy-saving pumps are used to optimise energy consumption. They are designed to reduce energy consumption while performing their functions. This is achieved through the use of innovative technologies, such as integrated control systems that adapt the pump to changing conditions. For example, circulation pumps with a frequency converter allow you to adjust the rotor speed, which makes it possible to operate only within the required capacity. This is an ideal solution for heating and water supply systems.

The use of a frequency converter reduces energy consumption, ensures a steady flow and avoids overloading the system. The variable pump speed allows the pump to be precisely adjusted to the needs of the system, which is important for energy conservation.

You can find out more about the circulation pump with frequency converter here.

November 25, 2024

Types of wind turbines

Tulip and H-type wind turbines have different designs and operating principles:

Tulip wind turbines

Design: Vertical wind turbines with a cylindrical shape and curved blades resembling tulip petals.

Advantages:

Effectively operate at low wind speeds, making them ideal for urban and suburban areas.

Reduce noise and vibration due to their shape.

Require less space for installation.

Less hazardous to birds and bats.

Easier to maintain and repair.

H-type wind turbines

Design: Horizontal wind turbines with blades arranged on a horizontal axis.

Advantages:

High efficiency at high wind speeds.

Often used for large wind farms due to their power.

Can generate more energy in stable wind conditions.

Both types have their advantages and disadvantages, and the choice depends on specific conditions and needs.

In addition to the tulip and H-type wind turbines, there are several other main types of wind turbines:

Horizontal wind turbines (HAWT)

Design: The blades are arranged on a horizontal axis.

Advantages:

High efficiency in stable wind conditions.

Often used in large wind farms, both on land and at sea.

Vertical Wind Turbines (VAWT)

Design: Blades are arranged on a vertical axis.

Advantages:

Can operate in variable wind directions.

Easier to maintain as generator and transmission are located closer to the ground.

Other types of wind turbines

Savonius: Vertical wind turbines with two or more curved blades that resemble a drum shape. Used for small installations.

Darrieus: Vertical wind turbines with “C” or “H” shaped blades. They are effective at high wind speeds.

Bladeless wind turbines: Use vibrations to generate power, which reduces noise and vibration.

Each type has its own unique characteristics and is suitable for different conditions and needs.

For a detailed overview of the principle of operation and the choice of the desired model, you can go to the website.