Catalog

Else categories

- Home

- Engineering services and equipmentVacuum evaporation plant Decanter centrifuges, separatorsCrushers for grinding cereal crops in the process of feed, flour, ethanol productionControl and measuring instruments, sensors, flow meters for production automationDesign, construction of a distillery, distillationSpiral shell and tube heat exchangerIndustrial dryersSolid fuel boilersEnzymes, alcohol yeast, antiseptics for the production of alcoholEnergy auditSteam industrial boilers

- Design, construction of a distillery, distillation

- Low-temperature cooking, distillery

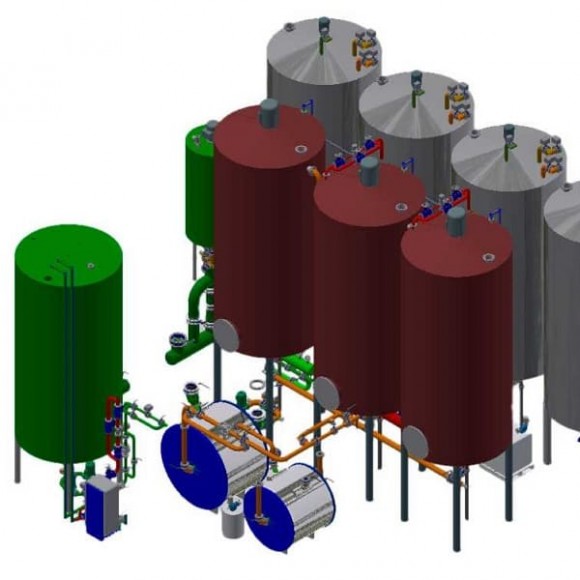

Low-temperature cooking, distillery

Overview

Design, construction, automation of the raw material boiling department, wheat, rye, corn...

Supervision of installation, commissioning, and start-up of low-temperature brewing for distilleries. Selection of enzyme preparations. The use of heat recovery in the boiling of raw materials-distillery.

The batch from the part-time department and the batch chunk is pumped to the department, where in the hydro-fermentation processing units, under the action of enzyme preparations, both introduced into the batch and additionally introduced into the hydro-fermentation processing apparatus, the batch is liquefied and saccharified to form a wort.

Characteristics

| Producer | BTS Engineering |

| Type | service |

| Consumption of hot steam, kg/liter (6 bar) | 2,5 – 4,0 |

| Electricity consumption, kW/liter | 0,5 |

| Artesian water, m3/liter | 0,002 |

| Consumption of circulating water, m3/liter (at the exit of the cooling tower 20˚C) | 0,2 |

| Consumption of fossil fuels, nm3/liter (on the example of natural gas) | 0,2 – 0,32 |

| Raw | grain crops, molasses, stream |

| Productivity, liter/day | 5000–100000 |

| Post-alcohol processing bards | Yes |

| The presence of ACS TP | Yes |

| Logistics data: |