Catalog

Else categories

- Home

- Engineering services and equipmentVacuum evaporation plant Decanter centrifuges, separatorsCrushers for grinding cereal crops in the process of feed, flour, ethanol productionControl and measuring instruments, sensors, flow meters for production automationDesign, construction of a distillery, distillationSpiral shell and tube heat exchangerIndustrial dryersSolid fuel boilersEnzymes, alcohol yeast, antiseptics for the production of alcoholEnergy auditSteam industrial boilers

- Design, construction of a distillery, distillation

- Distilled cognac plant 1500 dal/day

Distilled cognac plant 1500 dal/day

Overview

Distilled cognac plant 1500 dal/day includes:

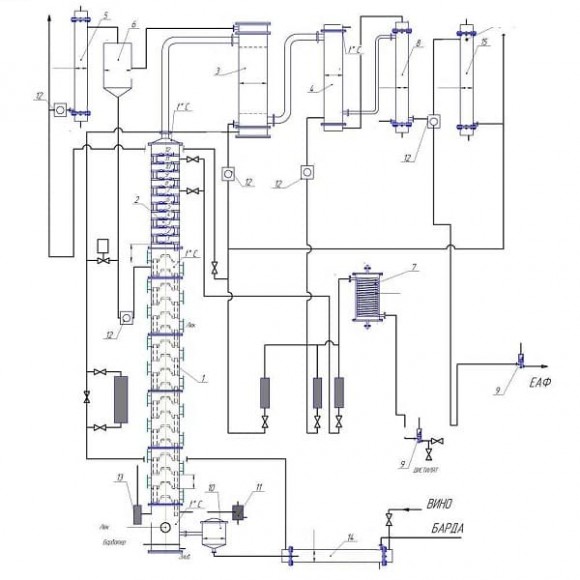

1. Double boiling column f1200, AISI 304, 18 plates +cube (1 piece)

2. Strengthening section f.1200, M3, 9 plates (1 piece)

3. Wine heater F=15m2, M3 (2 pcs)

4. Condenser F=15m2, M3 (1 piece)

5. Alcohol trap F=8m2, AISI304 (1 pc)

6. AISI304 vacuum breaker (2 pcs)

7. Refrigerator F=15m2( AISI304) + F=12m2, M3 (1 pc)

8. Diagram branch M3 (1 piece)

9. Recuperative wine heater F=30m2 AISI 304 (1 piece)

10. Alcohol trap F=9m2, AISI 316 (1 pc)

11. Regulator of distillery waste AISI 304 (1 piece)

12. Collection of distillery waste AISI 304 (1 piece)

13. Lanterns (7 pcs)

14. Solleron probe (1 piece)

15. CO2 separator ø1000 AISI 304 (1 piece)

16. Rotameters RM-0.16 ZHUS(1), RM-1.6 ZHUS(2) (3 pcs)

17. Rotameter RP-6,3 ZHUS (1 pc)

Characteristics

| Producer | BTS Engineering |

| Type | service |

| Consumption of hot steam, kg/liter (6 bar) | 2,5 – 4,0 |

| Electricity consumption, kW/liter | 0,5 |

| Artesian water, m3/liter | 0,002 |

| Consumption of circulating water, m3/liter (at the exit of the cooling tower 20˚C) | 0,2 |

| Consumption of fossil fuels, nm3/liter (on the example of natural gas) | 0,2 – 0,32 |

| Raw | grain crops, molasses, stream |

| Productivity, liter/day | 5000–100000 |

| Post-alcohol processing bards | Yes |

| The presence of ACS TP | Yes |

| Logistics data: |