Catalog

Else categories

- Home

- Engineering services and equipmentVacuum evaporation plant Decanter centrifuges, separatorsCrushers for grinding cereal crops in the process of feed, flour, ethanol productionControl and measuring instruments, sensors, flow meters for production automationDesign, construction of a distillery, distillationSpiral shell and tube heat exchangerIndustrial dryersSolid fuel boilersEnzymes, alcohol yeast, antiseptics for the production of alcoholEnergy auditSteam industrial boilers

- Design, construction of a distillery, distillation

- Out construction of offices for the processing of distillery stillage.

Out construction of offices for the processing of distillery stillage.

Overview

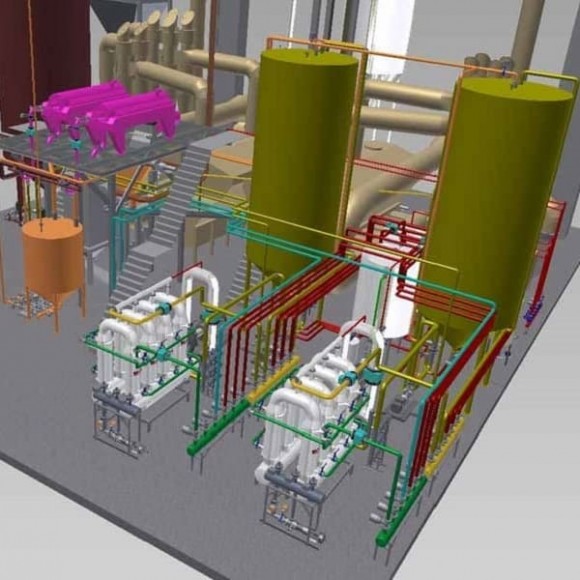

At the stage of distillation of alcohol, the main waste of its production is formed - distillery stillage. We offer the construction of distillery stillage processing units for existing alcohol production facilities.

Distillery stillage processing process:

The distillery stillage goes to a decanter (horizontal centrifuge), where it is divided into a solid fraction - cake (40% absolutely dry matter, then - ASV) and liquid - centrifuge (5.1% ASV).

The cake can be dispensed as a commercial product, but its storage time is limited to 12 hours, for this reason it is more efficient to dry it in order to obtain DDGS. Fugate, for further utilization and improvement of its quality as a commercial product, is thickened at the ultrafiltration unit to obtain another commercial product - concentrate (20 ... 23% DIA). It is possible to sell the concentrate for livestock feed, as an independent marketable product, but in order to improve the nutritional qualities of BVK, the concentrate is mixed with cake and dried.

Characteristics

| Producer | BTS Engineering |

| Type | service |

| Consumption of hot steam, kg/liter (6 bar) | 2,5 – 4,0 |

| Electricity consumption, kW/liter | 0,5 |

| Artesian water, m3/liter | 0,002 |

| Consumption of circulating water, m3/liter (at the exit of the cooling tower 20˚C) | 0,2 |

| Consumption of fossil fuels, nm3/liter (on the example of natural gas) | 0,2 – 0,32 |

| Raw | grain crops, molasses, stream |

| Productivity, liter/day | 5000–100000 |

| Post-alcohol processing bards | Yes |

| The presence of ACS TP | Yes |

| Logistics data: |

Products from the same category

1029011

Pre-order only