Catalog

Else categories

- Home

- Engineering services and equipmentVacuum evaporation plant Decanter centrifuges, separatorsCrushers for grinding cereal crops in the process of feed, flour, ethanol productionControl and measuring instruments, sensors, flow meters for production automationDesign, construction of a distillery, distillationSpiral shell and tube heat exchangerIndustrial dryersSolid fuel boilersEnzymes, alcohol yeast, antiseptics for the production of alcoholEnergy auditSteam industrial boilers

- Design, construction of a distillery, distillation

- Plants for the production of carbon dioxide from bioethanol fermentation products 1000 kg/h

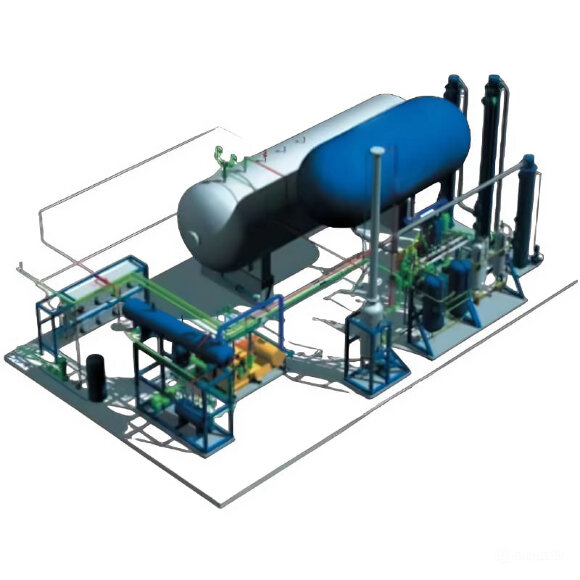

Plants for the production of carbon dioxide from bioethanol fermentation products 1000 kg/h

Documentation

Download instructions, catalog for Plants for the production of carbon dioxide from bioethanol fermentation products 1000 kg/h

Overview

Distilleries primarily produce edible alcohol from starchy raw materials. CO2 is the most important by-product generated in the alcohol fermentation process and has a high consumer value. It is known that the production process of alcohol fermentation involves the production of alcohol from starch of grain crops (wheat, corn) by saccharification and fermentation, with the simultaneous production of large amounts of CO2.

Technical parameters of the device for carbon dioxide production:

Ambient temperature (max.): 32C;

Volume of processed raw gas: 600 Nm3/h;

Inlet pressure: 0.1-0.5 kPa;

CO2 content in raw materials: more than 97%;

Recovery rate: 75%;

Product purity: food grade CO2 liquid with purity of 99.99% or more; complies with the latest national standard GB10621-2006;

Vertical double layer vacuum storage tank: 150 m3;

Capacity: 1000 kg/h;

Power supply: 380 V 50-60 Hz total power: about 260 kW;

Water consumption: 8 m3/hour.

Characteristics

| Productivity of the finished product, t/h | 1 |

| Producer | BTS Engineering |

| Logistics data: |