Catalog

Else categories

- Home

- Engineering services and equipmentVacuum evaporation plant Decanter centrifuges, separatorsCrushers for grinding cereal crops in the process of feed, flour, ethanol productionControl and measuring instruments, sensors, flow meters for production automationDesign, construction of a distillery, distillationSpiral shell and tube heat exchangerIndustrial dryersSolid fuel boilersEnzymes, alcohol yeast, antiseptics for the production of alcoholEnergy auditSteam industrial boilers

- Industrial dryers

- The distillery dreg drying line 1-1. 2 tons per hour of finished DDGS product

The distillery dreg drying line 1-1. 2 tons per hour of finished DDGS product

Documentation

Download instructions, catalog for The distillery dreg drying line 1-1. 2 tons per hour of finished DDGS product

Overview

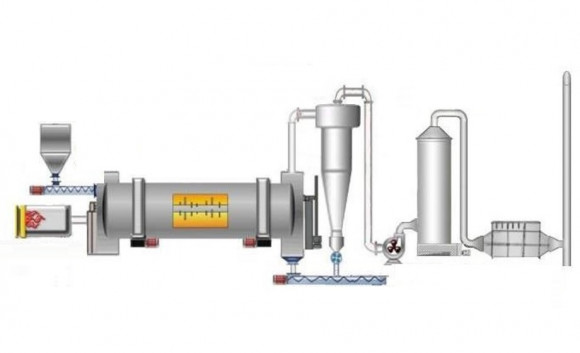

The distillery dreg drying line 1-1.2 tons per hour of finished DDGS product.

Initial humidity of raw materials (Cake): 63% ± 1%; raw material productivity (Cake): 2.5 -3.0 t / h;

DDGs humidity after drying: 10 ± 1%; final product Yield: 1.0 -1.2 t / h;

Maximum temperature of the incoming hot air flow: 600-700°C. Exhaust gas temperature: 70 -80°C;

Drying temperature: no more than 65°C;

Main equipment:

1. Drum dryer model DLJG 2010/3-1 set,

2. Auxiliary equipment for heat supply, drying, dust extraction, conveyors and electrical control;

Fuel pellet consumption: 320 - 380 kg / h;

Total installed electrical power: 112.1 KW/ H; rated electrical power: 103± 10 kw / h;

Required space for placing the drying line: 25m * 8m * 8m

Number of personnel for each shift: 2 apparatchiks.

Characteristics

| Productivity of the finished product, t/h | 1,0-1,2 |

| Productivity of raw materials, t/h | 2,5-3,0 |

| Producer | BTS Engineering |

| Power supply | 3х380 V, 50 Hz |

| Model | DLJG 2010/3 |

| The amount of evaporated moisture, kg/hour | 2 000 |

| Application | distillery stillage processing (DDGS) |

| Logistics data: |