Catalog

Else categories

- Home

- Engineering services and equipmentVacuum evaporation plant Decanter centrifuges, separatorsCrushers for grinding cereal crops in the process of feed, flour, ethanol productionControl and measuring instruments, sensors, flow meters for production automationDesign, construction of a distillery, distillationSpiral shell and tube heat exchangerIndustrial dryersSolid fuel boilersEnzymes, alcohol yeast, antiseptics for the production of alcoholEnergy auditSteam industrial boilers

- Spiral shell and tube heat exchanger

- Spiral heat exchanger 60m2, 12/14 AISI 304

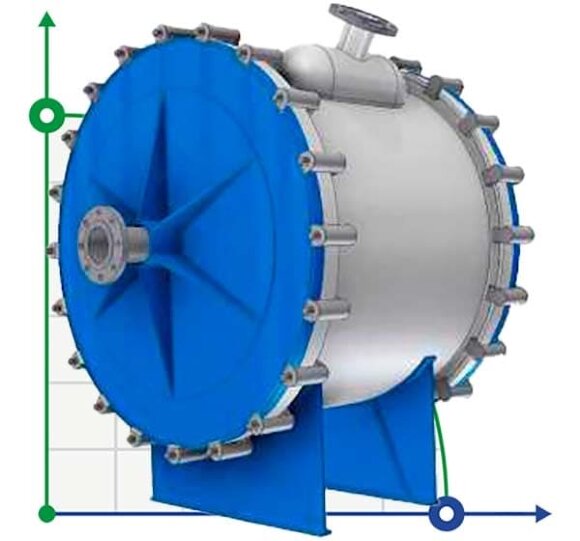

Spiral heat exchanger 60m2, 12/14 AISI 304

Overview

Spiral heat exchanger 60M2

Design pressure 0.6MPa

Design temperature 150C

HTA: 60M2

The spiral plate 2.5mm, the channel space 12/14mm, the width 500mm, SS304

The outside shell OD1600*500*10mm, SS304

The nozzle DN100PN16

The cover and shell flange material is Q345R+SS304

Spiral heat exchangers are widely used in various industries due to their advantages over other types of heat exchangers.

Spiral heat exchangers are used as condensers, evaporators, and for cooling and heating liquids, gases, and vapour-gas mixtures.

Distillation columns can be equipped with spiral heat exchangers as deflagration units.

Spiral heat exchangers are particularly effective for the treatment of highly viscous liquids, as the problem of distributing such liquids through pipes is eliminated, as well as for the treatment of sludges and liquids containing fibrous materials and inclusions.

Characteristics

| Production period, days | ≥ 60 |

| Producer | BTS Engineering |

| Material | AISI 304 stainless steel |

| Pressure | 0,6 MPa |

| Max.temperature, C | 150 |

| Type of heat exchanger | spiral |

| Area, m2 | 60 |

| Pipe diameter of hot side,mm | DN100 |

| Pipe diametr of cold side,mm | DN100 |

| Channel size mm/mm | 12/14 |

| Analogue for | Alfa Laval, Danfoss, FAMET S.A., FUNKE, GEA Wigand, GEA, RELIZ, SECESPOL, SONDEX, SWEP, Tetra Pak, Vogelbusch, Винпромсервис, Опытно механический завод Винница |

| Logistics data: |