Catalog

Else categories

- Home

- Engineering services and equipmentVacuum evaporation plant Decanter centrifuges, separatorsCrushers for grinding cereal crops in the process of feed, flour, ethanol productionControl and measuring instruments, sensors, flow meters for production automationDesign, construction of a distillery, distillationSpiral shell and tube heat exchangerIndustrial dryersSolid fuel boilersEnzymes, alcohol yeast, antiseptics for the production of alcoholEnergy auditSteam industrial boilers

- Spiral shell and tube heat exchanger

- Recuperative heat exchanger for sludge 160m2 steel duplex SS UNS31803

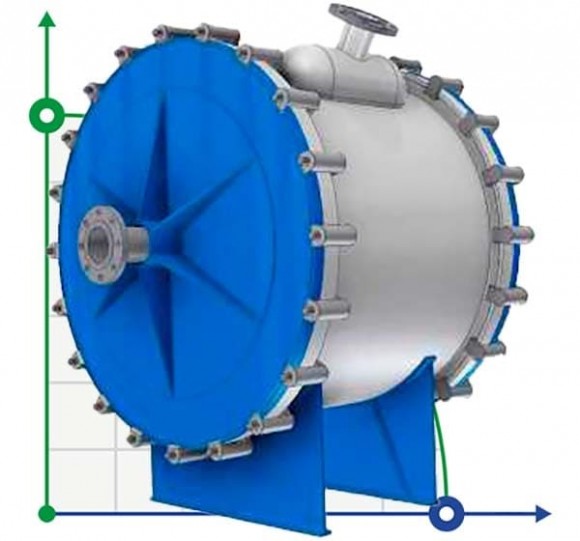

Recuperative heat exchanger for sludge 160m2 steel duplex SS UNS31803

Documentation

Download instructions, catalog for Recuperative heat exchanger for sludge 160m2 steel duplex SS UNS31803

Overview

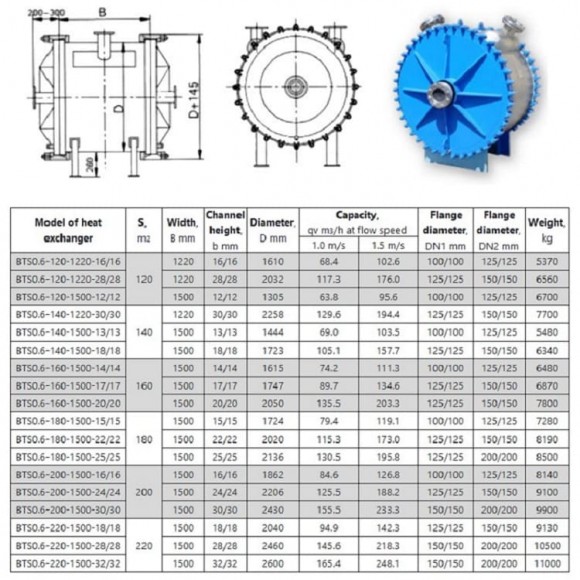

The spiral heat exchanger is made of steel with a thickness of 2.5 mm and a spiral width of 2000 mm. The heat transfer area of the spiral heat exchanger was 156 m2, with the amount of contamination taken into account.

Duplex S31803-stainless steel with a microstructure of austenite and ferrite in equal parts.

It is optimal for use in cases where there are increased requirements for mechanical strength and corrosion resistance.

Horizontal spiral heat exchanger with Duplex steel Duplex SS UNS31803, heating capacity 4400 kW.

The heat exchanger will be used for cooling Rhenium sulfate (Rhenium (VI) Sulfate).

- Heat exchange area of 160 sq. m.

- The width of the spiral is 2000 mm.

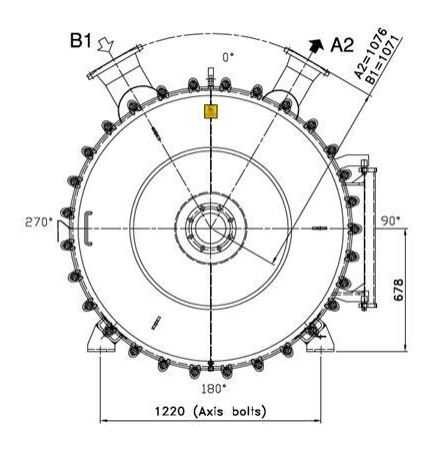

- The diameter of the heat exchanger is 1500 mm.

- Flow diagram of the coolant-counterflow.

- The heat exchanger is designed to operate under a coolant pressure of 6.0 bar.

- Empty heat exchanger weight 5840 kg.

The concept of a spiral heat exchanger is based on twisting 2 or 4 strips of metal around the Central pipe, the strips are welded together using dividing pins at a certain distance, creating 2 or 4 channels of uniform width. The Central pipe is divided into 2 parts, forming an input and output collector. The entire structure is placed in a cylindrical housing. The outer ends of the sheets are welded along the collectors, forming the remaining two inlet and outlet pipes on the side of the housing.

Characteristics

| Production period, days | ≥ 60 |

| Producer | BTS Engineering |

| Material | Duplex steel duplex SS UNS31803 |

| Material | Duplex SS UNS31803 |

| Type | collapsible |

| Calculated pressure of the hot side, MPa | 0.6 |

| Design-basis pressure of cold water Mpag | 0.65 |

| Calculated temperature (max),C | 90 |

| Type of heat exchanger | spiral |

| Area, m2 | 160 |

| Pipe diameter of hot side,mm | DN150 |

| Pipe diametr of cold side,mm | DN200 |

| Application | bards, brew, water, oils, heating, petroleum products, cooling, products, recovery, drains, wort, serum, fuel, fermentation, filtrate, chemistry, sludge |

| Analogue for | Alfa Laval, Danfoss, FAMET S.A., FUNKE, GEA, GEA Wigand, RELIZ, SECESPOL, SONDEX, SWEP, Tetra Pak, Vogelbusch, Винпромсервис, Опытно механический завод Винница |

| Logistics data: |