Catalog

Else categories

- Home

- Industrial pumps

- Pumps by typeBarrel pumps Vacuum pumpsVertical semi-submersible pumpsScrew pumpsVortex pumpsHermetic pumpsDispersant-emulsifier, homogenizerDosing pumpsImpeller pumpsSewer stationsCantilever pumpsLobe pumpsDiaphragm pumpsPneumatic diaphragm submersible pumpsMultistage pumpsCast iron monobloc pumpsMotor pumpsMotor diaphragm pumpsEx ATEX pumpPTO driven pumpDouble inlet pumpsInline pumpsGlandless pumpsAxial pumpsPeristaltic pumpsRotary vane pumpsPlunger pumpsSemi-submersible fecal, drainage pumpSubmersible drainage and fecal pumpsSubmersible slurry pumpsPiston pumpsRoller pumps Self-priming centrifgual pumpSanitary, hygienic pumpsBorehole pumpsSolenoid pump dispenserWater supply and fire extinguishing stationsChemical magnetic pumpsCentrifugal pumpsGear pumpsIndustrial hose peristaltic pumps

- Axial pumps

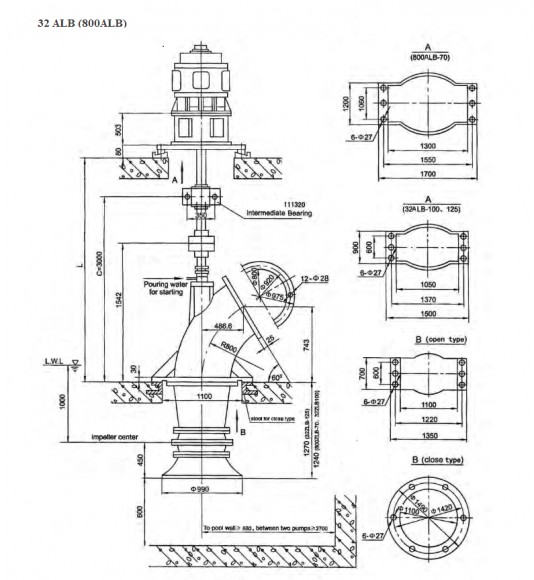

- Axial pump 20ALB-70, 1760 m3/h, 55 kW, 980r/min (without motor)

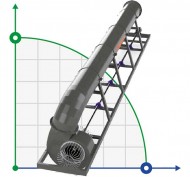

Axial pump 20ALB-70, 1760 m3/h, 55 kW, 980r/min (without motor)

Also buy with this product

1042539

Pre-order only

Overview

Axial pumps are intended mainly for the supply of large volumes of liquids. Their work is due to the transfer of the energy that the liquid receives when the frontal surface of the rotating blades of the impeller is forcefully exposed to it. At the same time, the particles of the supplied liquid have curved trajectories, but after passing through the straightening apparatus, they begin to move from the entrance to the pump to the exit from it, mainly along its axis (hence the name).

There are 2 main types of axial pumps: rigid-bladed with blades fixed motionlessly on the impeller sleeve, called propeller, and rotary-bladed, equipped with a mechanism for changing the angle of inclination of the blades. Pumps of both varieties are usually built single-stage, less often two-stage.

A distinctive feature of axial pumps is the design and operation of the impeller. It consists of a sleeve on which several blades are fixed, representing a conveniently streamlined curved wing with a twisted front edge running into the flow. When the blade profile is moved, caused by the rotation of the impeller, in the liquid, due to a change in the velocity of its flow along the lower and upper surfaces of the profile, the pressure above the profile should increase, and under the profile - decrease. This creates a pump head.

Characteristics

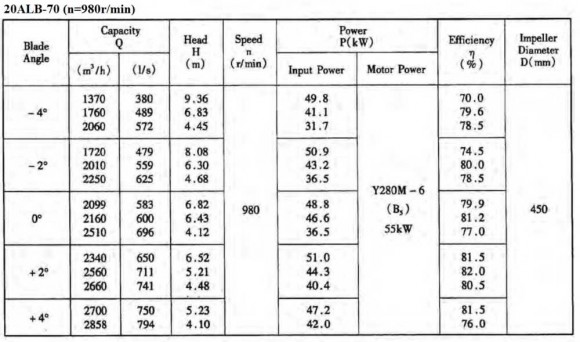

| Producer | BTS Engineering |

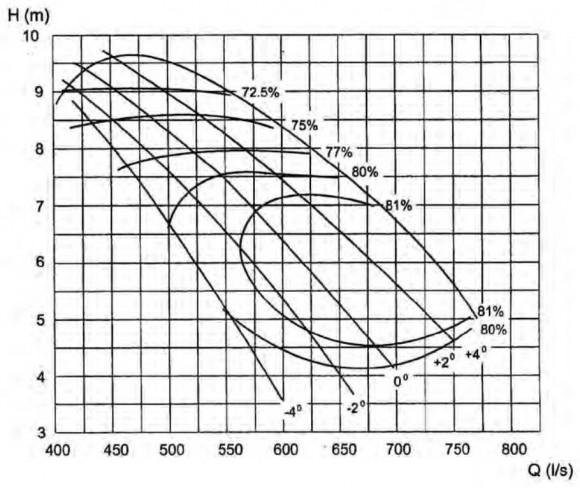

| Pump capacity, m3/h | 1760 |

| Feed height, m | 6.8 |

| Power capacity, kW | 55 |

| Material | cast iron |

| Nom.flow rate, m3/h | 1760 |

| Nom.head, m | 6.8 |

| Serial number of the pump | ALB |

| PumpType | axial |

| Drive Type | electric |

| Warranty, months | 12 |

| Logistics data: |

Categories:Axial pumpsPump for fish and seafoodPumps for lowering the flood water levelPumps for fish farming