Catalog

Else categories

- Home

- Industrial pumps

- Pumps by typeBarrel pumps Vacuum pumpsVertical semi-submersible pumpsScrew pumpsVortex pumpsHermetic pumpsDispersant-emulsifier, homogenizerDosing pumpsImpeller pumpsSewer stationsCantilever pumpsLobe pumpsDiaphragm pumpsPneumatic diaphragm submersible pumpsMultistage pumpsCast iron monobloc pumpsMotor pumpsMotor diaphragm pumpsEx ATEX pumpPTO driven pumpDouble inlet pumpsInline pumpsGlandless pumpsAxial pumpsPeristaltic pumpsRotary vane pumpsPlunger pumpsSemi-submersible fecal, drainage pumpSubmersible drainage and fecal pumpsSubmersible slurry pumpsPiston pumpsRoller pumps Self-priming centrifgual pumpSanitary, hygienic pumpsBorehole pumpsSolenoid pump dispenserWater supply and fire extinguishing stationsChemical magnetic pumpsCentrifugal pumpsGear pumpsIndustrial hose peristaltic pumps

- Barrel pumps

- Drum pumps Ex (explosion-proof electric motor)

- Drum pump BTS-HD-EX2-V+SS304-HP-1000mm

Drum pump BTS-HD-EX2-V+SS304-HP-1000mm

Also buy with this product

1042539

Pre-order only

Documentation

Download instructions, catalog for Drum pump BTS-HD-EX2-V+SS304-HP-1000mm

Overview

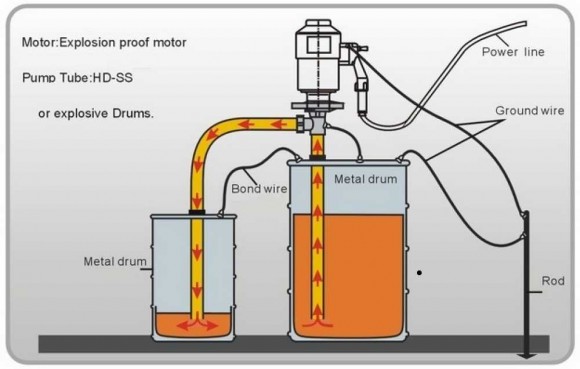

Drum pumps designated for transferring of various liquids from the cans, tanks and IBC containers. Drum pumps are made of different materials, e.g. stainless steel, Aluminum, PVC (poly vinyl chloride), Polypropylene and others.

The delivery of acids, alkalis and reagents in drums and IBC (intermediate bulk containers) became the common practice. Specified tare oftentimes is for turn back and it means that the tare must be tipped out quickly and carefully and the returned to sender. As the containers with down discharge forbidden in many countries because of the liquid restriction danger, the only possibility of pumping the liquid became the using of housing on lid. The best equipment for this work is drum pumps.

Drum pumps for chemically active liquids: sodium hydroxide, acetic acid, nitric acid, hydrofluoric acid and muriatic acid and others.

Drum pumps transfer food supplements, feed products, molasses, deckers, atomizers, liquid products – concentrates and ingredients. In industry: pumping and loading of reagents and liquids from plastic tare, IBCs and drums.

Drum pumps are widely used for transferring of petrochemicals, dissolvents, hardening agents and other components.

Characteristics

| Producer | BTS Engineering |

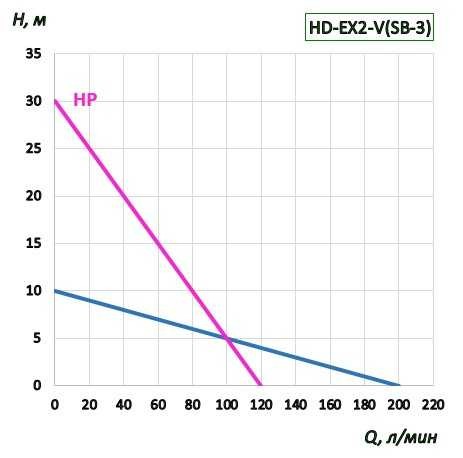

| Pump capacity, m3/h | 6 |

| Feed height, m | 30 |

| Material | AISI 304 stainless steel |

| Input pipe diameter | 42 mm |

| Output pipe diameter | 25 mm |

| Rate of turn, rpm | 12 000 |

| Power supply | 1х220 V, 50 Hz |

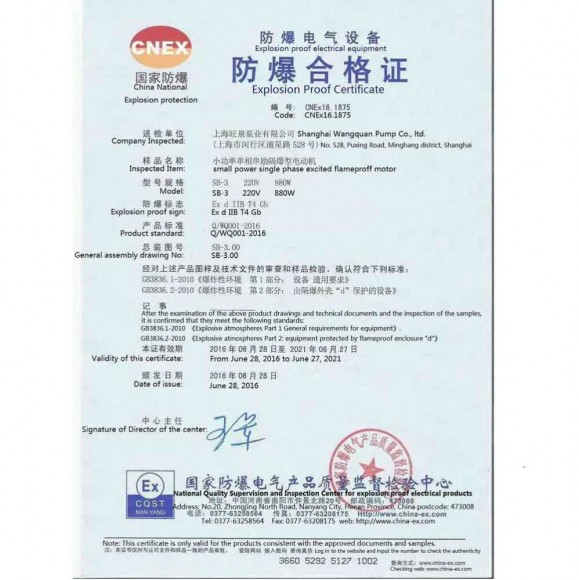

| Explosion protection | Yes |

| Power capacity, Wt | 880 |

| Model | BTS НР |

| Max.temperature, C | 100 |

| Length, mm | 1000 |

| Max.viscosity, cPs | 80 |

| Flow rate, l/min | 100 |

| Max. head, m | 30 |

| Height, mm | 1 000 |

| Material of flow channel | AISI 304 stainless steel |

| Shaft material | AISI 316L |

| Country of Origin | China |

| PumpType | drum |

| Drive Type | electric |

| Type of configuration | with engine |

| Availability of spare parts | Yes |

| Warranty, months | 12 |

| Application | CIP-washing, nitric acid, flavorings, barrel, cubic containers, acid, oils, petroleum products, hardeners, treacle, pigments, food additives, food, hydrofluoric acid, solvents, thickeners, of hydrochloric acid, fuel, acetic acid, enzymes, chemistry, chemically active liquids, alkalis |

| Analogue for | FLUIMAC, DAYTON, Debem, JESSBERGER, Lutz |

| Logistics data: |

Categories:Drum pumps Ex (explosion-proof electric motor)Pumps for hexanePumps for pumping alcohol ЕХ