Catalog

Else categories

- Home

- Industrial pumps

- Pumps by typeBarrel pumps Vacuum pumpsVertical semi-submersible pumpsScrew pumpsVortex pumpsHermetic pumpsDispersant-emulsifier, homogenizerDosing pumpsImpeller pumpsSewer stationsCantilever pumpsLobe pumpsDiaphragm pumpsMultistage pumpsCast iron monobloc pumpsMotor pumpsMotor diaphragm pumpsEx ATEX pumpPTO driven pumpDouble inlet pumpsInline pumpsGlandless pumpsAxial pumpsPeristaltic pumpsRotary vane pumpsPlunger pumpsSemi-submersible fecal, drainage pumpSubmersible drainage and fecal pumpsSubmersible slurry pumpsPiston pumpsRoller pumps Self-priming centrifgual pumpSanitary, hygienic pumpsBorehole pumpsSolenoid pump dispenserWater supply and fire extinguishing stationsChemical magnetic pumpsCentrifugal pumpsGear pumpsIndustrial hose peristaltic pumps

- Cantilever pumps

- Diesel fuel pump Ex plosion-proof BGWB 40-200 (I)A (11.7/44), 4kW, 2880, Ex

Diesel fuel pump Ex plosion-proof BGWB 40-200 (I)A (11.7/44), 4kW, 2880, Ex

Also buy with this product

Documentation

Download instructions, catalog for Diesel fuel pump Ex plosion-proof BGWB 40-200 (I)A (11.7/44), 4kW, 2880, Ex

Overview

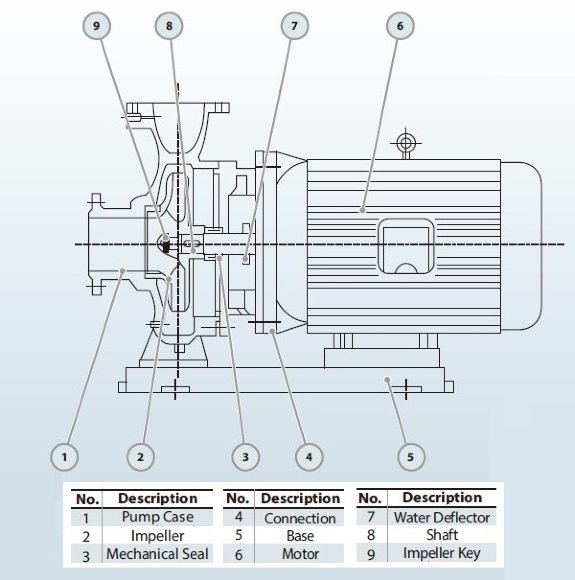

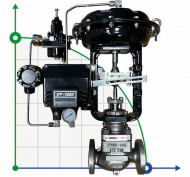

The BGWB series pump is a centrifugal explosion-proof pump for pumping diesel fuel, gasoline, petroleum products, diesel fuel, an analog of KM.

Monoblock centrifugal electric pumps with explosion-proof motor of the KM type, designed for pumping gasoline and other liquid petroleum products at temperatures from -40 to + 50°C, with a density of not more than 1000 kg/m3, a viscosity of 0.55 to 100 mm2/s, with a content of solid suspended particles in the amount of not more than 0.2% and a size of not more than 0.2 mm. The pumps are designed for operation in explosive areas of premises and outdoor installations of classes where explosive mixtures of combustible gases or gasoline vapors with air belonging to categories IIA and IIB, and explosion hazard groups T1, T2, T3, T4 can form.

In pumps for petroleum products or mixtures, the working bodies of the pump part are made of chrome-plated cast iron, the wheel in two versions is cast iron or stainless steel O-rings and a mechanical seal made of resistant rubber, a special single or double mechanical seal is used. Asynchronous three-phase explosion-proof electric motor.

Pump for pumping diesel fuel and gasoline, analog of KM pumps three-phase explosion-proof industrial.

Due to the low weight and small dimensions of the industrial pump, it can be used as a mobile pump or mobile pump.

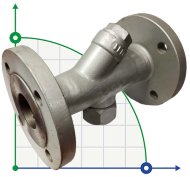

Connection to fuel lines – flanges.

It is not allowed to operate the pump without liquid, "in dry". Before switching on the pump, all pipelines and the pump part must be filled with the pumped liquid.

The pump must be operated in accordance with all labor protection and fire safety regulations.

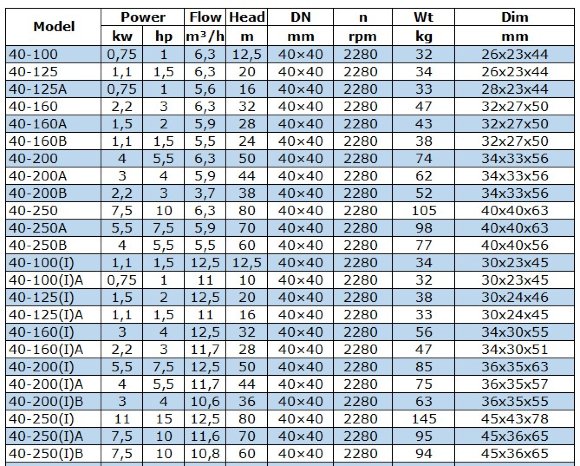

Characteristics

| Producer | BTS Engineering |

| Pump capacity, cu.m/hour | 11.7 |

| Feed height, m | 44 |

| Power capacity, kW | 4 |

| Material | cast iron |

| Input pipe diameter | 40 |

| Output pipe diameter | 40 |

| Rate of turn, rpm | 2 880 |

| Protection | IP55 |

| Power supply | 3х380 V, 50 Hz |

| Explosion protection | Yes |

| Max.temperature, C | 120 |

| Nom.flow rate, m3/h | 11.7 |

| Dimensions, mm | 360x350x570 |

| Nom.head, m | 44 |

| Seal | Mechanical Seal, Carbon-SiC-NBR |

| Material of flow channel | cast iron |

| Serial number of the pump | BGWB |

| Country of Origin | China |

| PumpType | console |

| Drive Type | electric |

| Installation Type | horizontal |

| Type of configuration | with engine |

| Warranty, months | 12 |

| Application | diesel fuel, gasoline pumping, diesel fuel pumping, petroleum products |

| Logistics data: |

Categories:Cantilever pumpsEx ATEX pumpPumps for petroleum products, gasoline, diesel fuel