Catalog

Else categories

- Home

- Industrial pumps

- Pumps by typeBarrel pumps Vacuum pumpsVertical semi-submersible pumpsScrew pumpsVortex pumpsHermetic pumpsDispersant-emulsifier, homogenizerDosing pumpsImpeller pumpsSewer stationsCantilever pumpsLobe pumpsDiaphragm pumpsPneumatic diaphragm submersible pumpsMultistage pumpsCast iron monobloc pumpsMotor pumpsMotor diaphragm pumpsEx ATEX pumpPTO driven pumpDouble inlet pumpsInline pumpsGlandless pumpsAxial pumpsPeristaltic pumpsRotary vane pumpsPlunger pumpsSemi-submersible fecal, drainage pumpSubmersible drainage and fecal pumpsSubmersible slurry pumpsPiston pumpsRoller pumps Self-priming centrifgual pumpSanitary, hygienic pumpsBorehole pumpsSolenoid pump dispenserWater supply and fire extinguishing stationsChemical magnetic pumpsCentrifugal pumpsGear pumpsIndustrial hose peristaltic pumps

- Gear pumps

- Gear pump for viscous products EMSE EDP 1030, DN80, 30 m3/h, 4 bar, 11 kW, 1000 rpm, carbon steel, Ex, PLAN 01 API SEAL

Gear pump for viscous products EMSE EDP 1030, DN80, 30 m3/h, 4 bar, 11 kW, 1000 rpm, carbon steel, Ex, PLAN 01 API SEAL

Also buy with this product

1042539

Pre-order only

Documentation

Download instructions, catalog for Gear pump for viscous products EMSE EDP 1030, DN80, 30 m3/h, 4 bar, 11 kW, 1000 rpm, carbon steel, Ex, PLAN 01 API SEAL

Overview

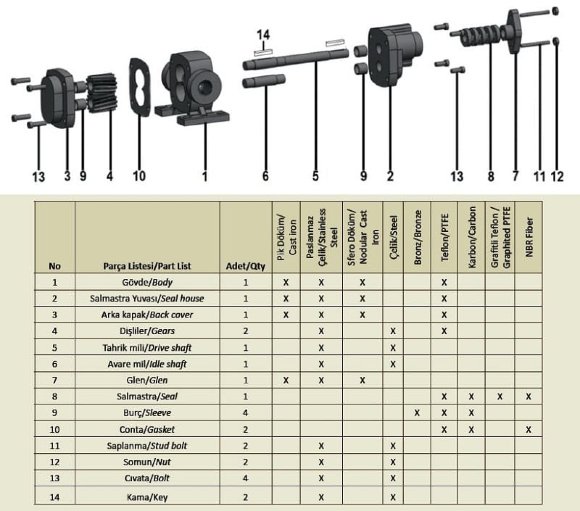

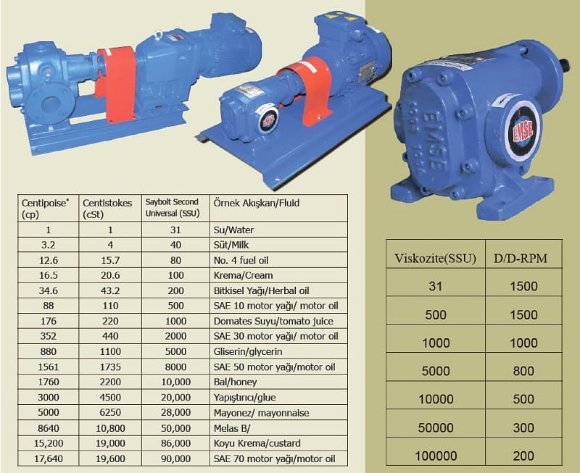

EMSE gear pumps of the EDP series, depending on the material of the gear part (cast iron, stainless steel), can pump viscous liquids such as fuel oil, polyester components, caustic resin, oil, glue, mineral oil, gel, grease, chocolate, soap raw materials, glucose, quaternary esters, glycerin, rubber, wax, honey, molasses, oil and many other liquids.

The principle of operation: as a result of the rotation of the gears in constant engagement, a low and high pressure zone is formed. As a result, the fluid is drawn into the suction nozzle and, moving in the gap between the gear teeth and the housing, enters the discharge zone to the discharge nozzle.

Gear pumps are reversible and can operate in both directions. These pumps can be connected to a drive in a variety of ways. These include: direct connection to an electric motor via a coupling, connection via a gearbox, connection via a V-belt drive, connection to a variable speed drive. (This connection method allows the speed of rotation to be varied and thus the flow to be controlled.)

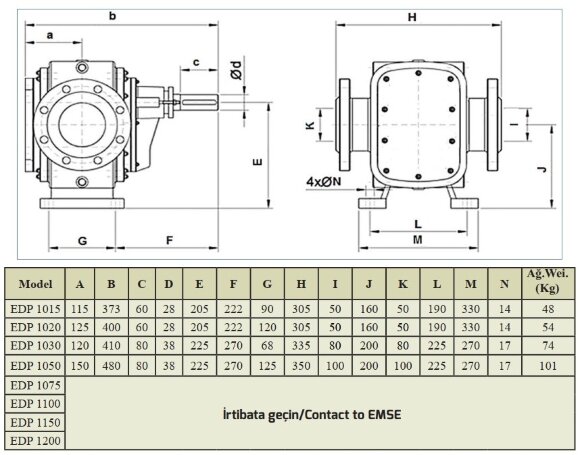

EDP pumps from model 1015 onwards are available with a casing with a heating jacket as standard. This feature allows for a wider range of process applications for pumping products that are prone to crystallisation at lower temperatures.

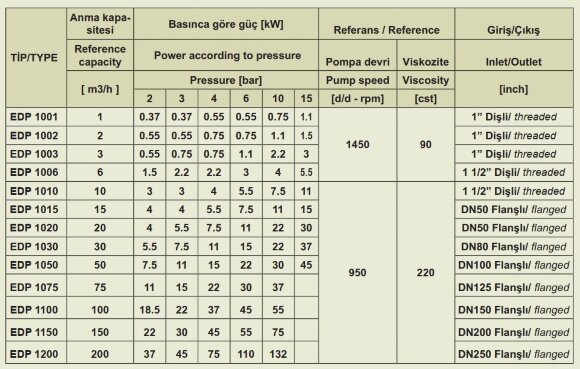

Characteristics

| Gear meshing type | external |

| Producer | EMSE |

| Pump capacity, m3/h | 30 |

| Power capacity, kW | 11 |

| Material | carbon steel |

| Input pipe diameter | DN80 |

| Output pipe diameter | DN80 |

| Rate of turn, rpm | 1 000 |

| Explosion protection | Yes |

| Max.temperature, C | 250 |

| Pressure, bar | 4 |

| Housing material | carbon steel |

| Country of Origin | Turkey |

| PumpType | gear type |

| Drive Type | electric |

| Installation Type | horizontal |

| Type of configuration | with engine |

| Logistics data: |

Products from the same category

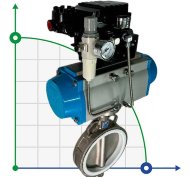

1044219

Pre-order only