Catalog

Else categories

- Home

- Industrial pumps

- Pumps by typeBarrel pumps Vacuum pumpsVertical semi-submersible pumpsScrew pumpsVortex pumpsHermetic pumpsDispersant-emulsifier, homogenizerDosing pumpsImpeller pumpsSewer stationsCantilever pumpsLobe pumpsDiaphragm pumpsPneumatic diaphragm submersible pumpsMultistage pumpsCast iron monobloc pumpsMotor pumpsMotor diaphragm pumpsEx ATEX pumpPTO driven pumpDouble inlet pumpsInline pumpsGlandless pumpsAxial pumpsPeristaltic pumpsRotary vane pumpsPlunger pumpsSemi-submersible fecal, drainage pumpSubmersible drainage and fecal pumpsSubmersible slurry pumpsPiston pumpsRoller pumps Self-priming centrifgual pumpSanitary, hygienic pumpsBorehole pumpsSolenoid pump dispenserWater supply and fire extinguishing stationsChemical magnetic pumpsCentrifugal pumpsGear pumpsIndustrial hose peristaltic pumps

- Gear pumps

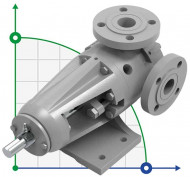

- Kupar KIPK Gear Pump 2 Inch-C, AISI 316, 1.5-7.5 m3/h stainless steel

Kupar KIPK Gear Pump 2 Inch-C, AISI 316, 1.5-7.5 m3/h stainless steel

Also buy with this product

1042539

Pre-order only

Documentation

Download instructions, catalog for Kupar KIPK Gear Pump 2 Inch-C, AISI 316, 1.5-7.5 m3/h stainless steel

Overview

The most important criterion when choosing the type of gear pumps is the viscosity of the product.

The main criteria when choosing a gear pump:

- pump type: the basic principle is that external gear engagement is used for relatively low-viscosity fluids, and internal gear engagement for high-viscosity fluids.

- the size of the nozzles: the size of the nozzles and connecting pipelines are also related to the viscosity of the product. When choosing the type of pump and designing the pipeline system, the diameters of the pipelines should be accurately calculated in order to achieve the optimal flow rate for the liquid of the given viscosity.

In this case, a direct relationship is valid - for liquids with a higher viscosity should be used pipes of a larger diameter.

- pump rotation speed: the maximum speed for gear pumps is 1500 rpm. It decreases as the viscosity increases. High speeds should be chosen for low viscosity, low speeds for high viscosity.

The direct clutch with the electric motor is used at 1000 and 1500 rpm. For 500 rpm. and below - clutching with the electric motor is carried out through a gearbox or V-belt transmission.

-operational tolerances: operating clearances are set during pump manufacturing, some clearances are adjusted during pump assembly, according to viscosity ranges.

To pump a certain type of liquid, you should use a pump with appropriate working clearances, otherwise the pump may work with less pressure or stop completely.

Characteristics

| Flow Rate, L/rev | 0,263 |

| Pressure range, bar | 2-14 |

| Gear meshing type | internal |

| Producer | KUPAR |

| Pump capacity, m3/h | 7.5 |

| Power capacity, kW | 2,2 |

| Material | AISI 316 stainless steel |

| Input pipe diameter | 2" |

| Output pipe diameter | 2" |

| Rate of turn, rpm | 475 |

| Max.flow rate, m3/h | 7.5 |

| Operating temperature | 20°C +200°C |

| Max.viscosity, cPs | 25 000 |

| Dimensions, mm | 450x260x230 |

| Housing material | AISI 316 stainless steel |

| Serial number of the pump | KIPK |

| Country of Origin | Turkey |

| PumpType | gear type |

| Installation Type | horizontal |

| Logistics data: | |

| Weight, kg | 40 |

Categories:Gear pumpsPump for liquid glassPump for syrupSour cream pumpPump for emulsions and suspensionsPump for spice and saltGlycerin pumpsPumps for an ice creamVegetable oil pumpsGear pumps made of stainless steelFood pumps