Catalog

Else categories

- Home

- Industrial pumps

- Pumps by typeBarrel pumps Vacuum pumpsVertical semi-submersible pumpsScrew pumpsVortex pumpsHermetic pumpsDispersant-emulsifier, homogenizerDosing pumpsImpeller pumpsSewer stationsCantilever pumpsLobe pumpsDiaphragm pumpsPneumatic diaphragm submersible pumpsMultistage pumpsCast iron monobloc pumpsMotor pumpsMotor diaphragm pumpsEx ATEX pumpPTO driven pumpDouble inlet pumpsInline pumpsGlandless pumpsAxial pumpsPeristaltic pumpsRotary vane pumpsPlunger pumpsSemi-submersible fecal, drainage pumpSubmersible drainage and fecal pumpsSubmersible slurry pumpsPiston pumpsRoller pumps Self-priming centrifgual pumpSanitary, hygienic pumpsBorehole pumpsSolenoid pump dispenserWater supply and fire extinguishing stationsChemical magnetic pumpsCentrifugal pumpsGear pumpsIndustrial hose peristaltic pumps

- Inline pumps

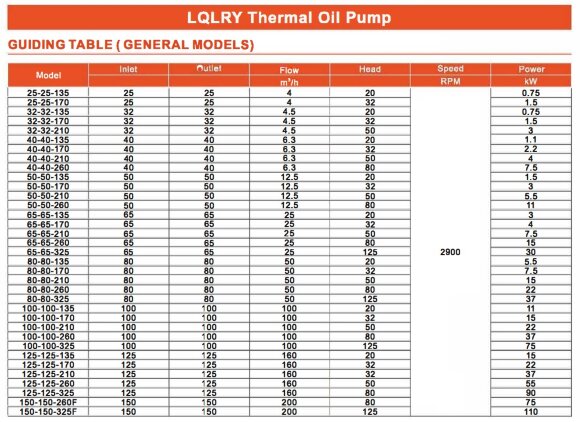

- High temperature oil circulation pump LQLRY100-100-210/2-CEX, 100 m3/h, 50 m, 22 kW, 2900 rpm, Ex

High temperature oil circulation pump LQLRY100-100-210/2-CEX, 100 m3/h, 50 m, 22 kW, 2900 rpm, Ex

Also buy with this product

1042539

Pre-order only

Documentation

Download instructions, catalog for High temperature oil circulation pump LQLRY100-100-210/2-CEX, 100 m3/h, 50 m, 22 kW, 2900 rpm, Ex

Overview

Thermo-oil pumps are designed to pump heat transfer fluids with temperatures up to 350°C in heat exchange systems without the need for external cooling of the pump.

The pumped liquids must have lubricating properties and be free of solid or abrasive particles, as the drive bearing and mechanical seal are not lubricated by the pumped liquid.

Applications of thermal oil pumps: chemical and pharmaceutical industry, mineral oil, food industry, leather and textile industry, woodworking, paint and varnish industry, construction, tar and bitumen, electrical industry

The LQLRY thermal oil pump complies with EN733 (DIN24255).

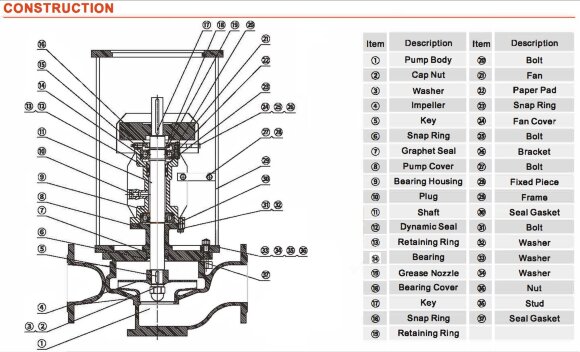

The unique design of the bearing housing with heat dissipation ensures a reduced temperature on the surfaces of the dynamic seal (or mechanical seal) and the bearings.

These pumps are additionally equipped with a safety seal and a throttle valve upstream of the dynamic seal (or mechanical seal). In the event of a seal failure, this prevents the pumped liquid from escaping in dangerous quantities. With a properly connected drain connection, the safety requirements of DIN 4754 are met in full. (The pumps are fitted with a drain connection to ensure that any leakage past the shaft seal is safely discharged through this connection.)

High temperature casings are fitted wherever possible.

Due to the unique heat dissipation design, no special protective cover is required for the coupling.

Characteristics

| Producer | BTS Engineering |

| Pump capacity, m3/h | 100 |

| Feed height, m | 50 |

| Power capacity, kW | 22 |

| Material | carbon steel |

| Input pipe diameter | DN100 |

| Output pipe diameter | DN100 |

| Rate of turn, rpm | 2 900 |

| Power supply | 3х380 V, 50 Hz |

| Explosion protection | Yes |

| Max.temperature, C | 350 |

| Seal | Dynamic Seal |

| Pressure, bar | 16 |

| Impeller material | carbon steel |

| Shaft material | 40Crmo |

| Serial number of the pump | LQLRY |

| Country of Origin | China |

| PumpType | in-line |

| Drive Type | electric |

| Installation Type | vertical |

| Type of configuration | with engine |

| Warranty, months | 12 |

| Application | superheated water, thermal oil |

| Logistics data: | |

| Weight, kg | 280 |

| Gross weight, kg | 328 |

| Length of transport packing, cm | 62 |

| Width of transport packing, cm | 72 |

| Height of transport packing, cm | 149 |

| Transport packing volume, cbm | 0,67 |

Categories:Inline pumpsCentrifugal pumpsThermal oil pumps +350High temperature pumps +400°C