Catalog

Else categories

- Home

- Industrial pumps

- Pumps by typeBarrel pumps Vacuum pumpsVertical semi-submersible pumpsScrew pumpsVortex pumpsHermetic pumpsDispersant-emulsifier, homogenizerDosing pumpsImpeller pumpsSewer stationsCantilever pumpsLobe pumpsDiaphragm pumpsPneumatic diaphragm submersible pumpsMultistage pumpsCast iron monobloc pumpsMotor pumpsMotor diaphragm pumpsEx ATEX pumpPTO driven pumpDouble inlet pumpsInline pumpsGlandless pumpsAxial pumpsPeristaltic pumpsRotary vane pumpsPlunger pumpsSemi-submersible fecal, drainage pumpSubmersible drainage and fecal pumpsSubmersible slurry pumpsPiston pumpsRoller pumps Self-priming centrifgual pumpSanitary, hygienic pumpsBorehole pumpsSolenoid pump dispenserWater supply and fire extinguishing stationsChemical magnetic pumpsCentrifugal pumpsGear pumpsIndustrial hose peristaltic pumps

- Chemical magnetic pumps

- ADM 40 PP/TF/4HP/2800RPM pump with the magnetic coupling

ADM 40 PP/TF/4HP/2800RPM pump with the magnetic coupling

Also buy with this product

1042539

Pre-order only

Documentation

Download instructions, catalog for ADM 40 PP/TF/4HP/2800RPM pump with the magnetic coupling

Overview

The centrifugal pumps with the magnetic coupling of the ADM series are made of thermoplastics (PP and PVDF) and are suitable for corrosive liquids.

Thanks to the innovative magnetic motion system, the ADM PP / PVDF pump model reduces the risk of loss and maintenance costs. The torque of the electric motor is transmitted to the pump by a magnetic coupling without mechanical contact. This ensures maximum safety and efficiency.

The ADM series centrifugal pumps with the magnetic coupling have a special design without mechanical seal, which makes them suitable for pumping corrosive and dangerous liquids due to their high chemical resistance and lack of leaks.

The structure of the pump is very simple, which significantly reduces the cost of its maintenance, with subsequent savings in the cost of repairs and spare parts during the life of the pump. An external magnet placed on the torsion axis transmits motion to the inner axis. That, in turn, connects to the impeller, which rotates and pushes the contents through the pump.

Advantages:

- without mechanical axle seal

- motor and pump are mechanically separated from each other

- absolute tightness

- no need for maintenance

Applications: chemical, petrochemical, pharmaceutical, paper, textile, food processing, sugar factories, dairy plants, electronics, water treatment plants, any hazardous chemical liquids.

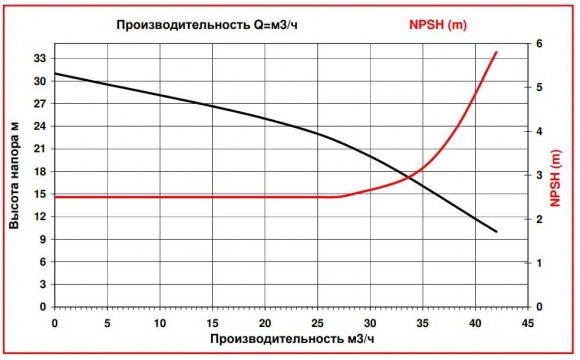

Technical characteristics of the pump:

Material of execution: PP

Max. Capacity: 42 m3 / h

Max. height of head: 31 mCe

Max. temperature: 60°C

Maximum viscosity: 200 cPs

Suction / discharge pipes: DN3 " x DN2 1/2"

Power: 3 kW, 3x380 V, 50 Hz, 3000 rpm.

Characteristics

| Producer | AlphaDynamic |

| Pump capacity, m3/h | 42 |

| Feed height, m | 31 |

| Power capacity, kW | 3 |

| Material | PP |

| Input pipe diameter | 3" |

| Output pipe diameter | 2 1/2" |

| Rate of turn, rpm | 3 000 |

| Power supply | 3х380 V, 50 Hz |

| Max.flow rate, m3/h | 42 |

| Model | ADM 40 |

| Max.temperature, C | 60 |

| Max.viscosity, cPs | 200 |

| Dimensions, mm | 595x250x280 |

| Max. head, m | 31 |

| Serial number of the pump | ADM |

| Country of Origin | Greece |

| PumpType | with magnetic coupling |

| Drive Type | electric |

| Installation Type | horizontal |

| Type of configuration | with engine |

| Availability of spare parts | Yes |

| Warranty, months | 12 |

| Logistics data: | |

| Weight, kg | 42 |

Categories:Chemical magnetic pumpsHermetic pumpsCentrifugal pumpsNitric acid pumpAcid-resistant pumps for aggressive liquidsPumps for aggressive liquids, acid pumpElectroplating pumps