Catalog

Else categories

- Home

- Industrial pumps

- Pumps by typeBarrel pumps Vacuum pumpsVertical semi-submersible pumpsScrew pumpsVortex pumpsHermetic pumpsDispersant-emulsifier, homogenizerDosing pumpsImpeller pumpsSewer stationsCantilever pumpsLobe pumpsDiaphragm pumpsPneumatic diaphragm submersible pumpsMultistage pumpsCast iron monobloc pumpsMotor pumpsMotor diaphragm pumpsEx ATEX pumpPTO driven pumpDouble inlet pumpsInline pumpsGlandless pumpsAxial pumpsPeristaltic pumpsRotary vane pumpsPlunger pumpsSemi-submersible fecal, drainage pumpSubmersible drainage and fecal pumpsSubmersible slurry pumpsPiston pumpsRoller pumps Self-priming centrifgual pumpSanitary, hygienic pumpsBorehole pumpsSolenoid pump dispenserWater supply and fire extinguishing stationsChemical magnetic pumpsCentrifugal pumpsGear pumpsIndustrial hose peristaltic pumps

- Sanitary, hygienic pumps

- Pump of cheese grain, tomato paste A9-KNA, 20m3/h, 4kW, 380V

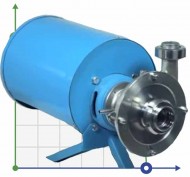

Pump of cheese grain, tomato paste A9-KNA, 20m3/h, 4kW, 380V

Also buy with this product

1042539

Pre-order only

Overview

The centrifugal food pump of the A9-KNA brand is a one-stage vane electric pump of monoblock type with horizontal installation. The main purpose of this pump is to pump cheese or grated (crushed) tomato mass (juice). Due to the complete set of the pump A9-KNA the 2-bladed impeller carries out uniform pumping of a product without breaking initial structure. In addition to tomato paste and cheese grains, this pump can be used to pump other chemically similar foods with a viscosity of up to 20 cSt (santistoks) = 20 mm ² / s and a temperature of up to 80 ° C. Productivity of this pump reaches 20,0 cubic meters / h at a pressure in 10,0 meters of a water column. The design of the pump is quite simple and consists of a motor (AIR100L4 - 4.0 kW / 1500 rpm), housing, working chamber and legs. In turn, the pump chamber includes suction and discharge pipes with connecting threads of dimensions DN80 and DN50 (according to DIN 11851), respectively. Also in a set to connecting carvings there are conic unions and cap nuts. In the pump chamber there is a 2-bladed impeller which fastens by means of a nut on a shaft-tip (at your request the A9-KNA pump can be equipped with an impeller with 4 blades). Also to avoid leakage of the product during pumping, this pump unit is equipped with an end seal type G2, which provides high tightness of the working chamber by means of a special spring support. The tightness of the pump is also ensured by means of a clamp (special fastening between the chamber and the pump housing), which also provides simplicity and ease of maintenance of the A9-KNA pump. It should be noted that all materials of the flowing part of the pump A9-KNA are made of stainless steel AISI 304 (08Х18Н10) approved for use in the chemical and food industries.

Characteristics

| Producer | MTS-Poltava |

| Pump capacity, m3/h | 20 |

| Feed height, m | 10 |

| Power capacity, kW | 4 |

| Material | AISI 304 stainless steel |

| Input pipe diameter | 80 mm |

| Output pipe diameter | 50 mm |

| Rate of turn, rpm | 1 500 |

| Power supply | 3х380 V, 50 Hz |

| Max.flow rate, m3/h | 20 |

| Max.temperature, C | 80 |

| Dimensions, mm | 595х320х400 |

| Nom.head, m | 10 |

| Serial number of the pump | A9-KNA |

| Country of Origin | Ukraine |

| PumpType | sanitary, hygienic |

| Drive Type | electric |

| Logistics data: | |

| Weight, kg | 62 |

Categories:Sanitary, hygienic pumpsPump for cheese grainWine pumpsMilk pumpsCentrifugal pumps made of stainless steelPumps for pumping milkFood pumps