Catalog

Else categories

- Home

- Industrial pumps

- Pumps by typeBarrel pumps Vacuum pumpsVertical semi-submersible pumpsScrew pumpsVortex pumpsHermetic pumpsDispersant-emulsifier, homogenizerDosing pumpsImpeller pumpsSewer stationsCantilever pumpsLobe pumpsDiaphragm pumpsPneumatic diaphragm submersible pumpsMultistage pumpsCast iron monobloc pumpsMotor pumpsMotor diaphragm pumpsEx ATEX pumpPTO driven pumpDouble inlet pumpsInline pumpsGlandless pumpsAxial pumpsPeristaltic pumpsRotary vane pumpsPlunger pumpsSemi-submersible fecal, drainage pumpSubmersible drainage and fecal pumpsSubmersible slurry pumpsPiston pumpsRoller pumps Self-priming centrifgual pumpSanitary, hygienic pumpsBorehole pumpsSolenoid pump dispenserWater supply and fire extinguishing stationsChemical magnetic pumpsCentrifugal pumpsGear pumpsIndustrial hose peristaltic pumps

- Submersible slurry pumps

- Submersible screw pump B0BQ-E01+BNBA4-GSEQ1AF+NW1A2OA—10

Submersible screw pump B0BQ-E01+BNBA4-GSEQ1AF+NW1A2OA—10

Also buy with this product

1042539

Pre-order only

Overview

Reliable submersible pump for abrasive or fibrous materials. Pumps with a submersible motor are reliable and easy to maintain. Meet the highest standards of quality and efficiency. Pumps are installed directly in the well, save space and lead to low costs.

Description: compact built-in unit; no open rotating shafts or couplings; quiet operation: hydraulics without clogging; reliable design for demanding applications; effective cooling reduces the heat load on the engine and minimizes the surface temperature; simple installation and recovery; a wide variety of monitoring and security options; vertical installation; cast iron body GG 25; impeller: high-strength cast iron with spherical graphite GGG 60; cable: rubber insulation, polyurethane sheath with flexible copper cores; shaft sealing: with a unit of two independent pairs of mechanical seals made of silicon carbide/silicon carbide and a dry inspection chamber between the seal unit and the stator; motor thermal protection: Klixon thermal constants, max. 2.5 A, 250 V (one in each winding).

The flow part consists of a single-channel, centrifugal-screw, non-clogging impeller of the Schraubentrifugalrad type, a stationary corresponding part with an unloading groove (suction cone/armor disk). The design provides for the replacement of the suction cone/armor disc without replacing the auger, which reduces the costs associated with a complete replacement of the auger. The pump is equipped with screw-centrifugal hydraulics and is capable of pumping general effluents and process liquids containing a large amount of solid and fibrous substances.

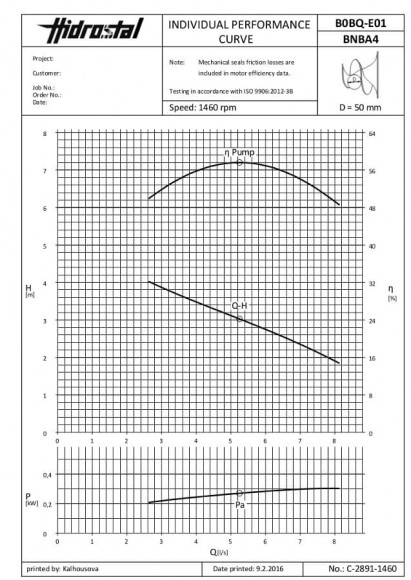

Technical characteristics: 4-pole, 3-phase asynchronous with a short-circuited rotor, a dry stator compartment and a rewinding stator; power 1.1kW; rotation frequency 1460 rpm; power supply 3x380 V, 50 Hz; nominal current 4.1 A; degree of protection IP68; direct start; insulation class F.

Applications: feces, mixed oil/water, sewage pumping sludge, sewer reconstruction, raw sewage, contaminated surface water, industrial sewage.

Features: helical centrifugal impeller with increased clogging resistance; can be used horizontally or vertically; high throughput of the rotating wheel.

Characteristics

| Producer | Hidrostal |

| Pump capacity, m3/h | 3.42 |

| Power capacity, kW | 1,1 |

| Material | cast iron |

| Input pipe diameter | DN65 |

| Output pipe diameter | DN65 |

| Rate of turn, rpm | 1 460 |

| Protection | IP68 |

| Power supply | 3х380 V, 50 Hz |

| Max.flow rate, m3/h | 3.42 |

| Max.temperature, C | 40 |

| Dimensions, mm | 285x510 |

| Seal | Mechanical Seal |

| Housing material | cast iron GG 25 |

| Impeller material | чавун GGG 60 |

| Country of Origin | Germany |

| Drive Type | electric |

| Installation Type | vertical |

| Logistics data: | |

| Weight, kg | 52 |