Catalog

Else categories

- Home

- Industrial pumps

- Pumps by typeBarrel pumps Vacuum pumpsVertical semi-submersible pumpsScrew pumpsVortex pumpsHermetic pumpsDispersant-emulsifier, homogenizerDosing pumpsImpeller pumpsSewer stationsCantilever pumpsLobe pumpsDiaphragm pumpsPneumatic diaphragm submersible pumpsMultistage pumpsCast iron monobloc pumpsMotor pumpsMotor diaphragm pumpsEx ATEX pumpPTO driven pumpDouble inlet pumpsInline pumpsGlandless pumpsAxial pumpsPeristaltic pumpsRotary vane pumpsPlunger pumpsSemi-submersible fecal, drainage pumpSubmersible drainage and fecal pumpsSubmersible slurry pumpsPiston pumpsRoller pumps Self-priming centrifgual pumpSanitary, hygienic pumpsBorehole pumpsSolenoid pump dispenserWater supply and fire extinguishing stationsChemical magnetic pumpsCentrifugal pumpsGear pumpsIndustrial hose peristaltic pumps

- Vertical semi-submersible pumps

- ADV 180/PVDF/1000/15HP/2800/BSP vertical centrifugal pump

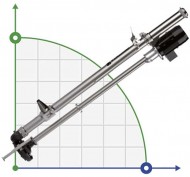

ADV 180/PVDF/1000/15HP/2800/BSP vertical centrifugal pump

Also buy with this product

1042539

Pre-order only

Documentation

Download instructions, catalog for ADV 180/PVDF/1000/15HP/2800/BSP vertical centrifugal pump

Overview

ADV series vertical centrifugal pumps made of thermoplastics (PP and PVDF) and are suitable for pumping hazardous and corrosive liquids with small solid suspension. ADV series is available with a height of 250 - 2000mm.

pump Description:

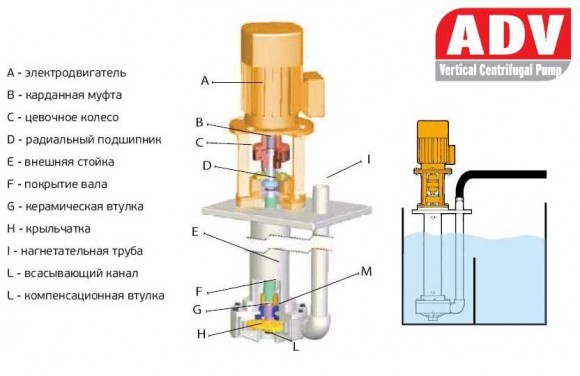

An open pump impeller allows constant even very dirty liquid having a viscosity of 500 cps (at 20 ° C) and small solid suspensions.

ADV vertical centrifugal pumps consist of a pressure hull, and rack fixed to the connection plate, which carries the pinwheel which is in turn the fastening element for the motor. The motor is secured to the pump shaft through a flexible coupling. Open impeller fixed to the other end of the shaft, which is supported by a radial sleeve.

The special design of the pump makes it possible to dismantle the engine without the need to disconnect the pump itself from the network.

Setting:

Axis vertical centrifugal pumps ADV installation must be located exclusively vertical manner and the pump must be immersed in a container. Pumps should be set so as to prevent dry running, and the possible formation of vortices of air suction. These pumps must work exclusively in the flooded state; dry running or air bubbles damage the inner sleeve.

Pump specifications:

Material performance: PVDF

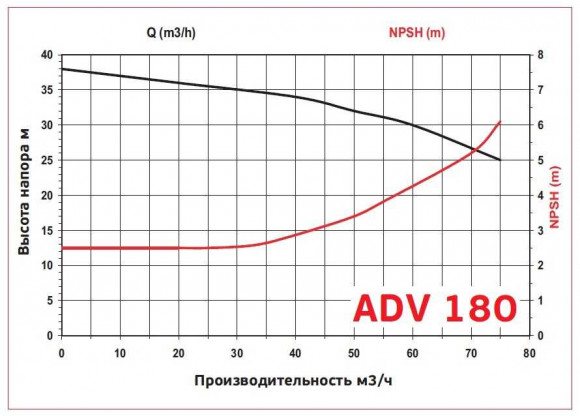

Max. Capacity: 75 m3 / h

Max. head height: 35 m.vod.st

Max.temperatura: 90 ° C

The maximum viscosity of 500 cps

Max. diameter solids: 11 mm.

Intake / delivery connections: DN65 x DN50

Power: 11 kW, 3x380 V, 50 Hz, 3000 rev / min.

Characteristics

| Producer | AlphaDynamic |

| Pump capacity, m3/h | 75 |

| Feed height, m | 35 |

| Power capacity, kW | 11 |

| Material | PP |

| Input pipe diameter | 65 mm |

| Output pipe diameter | 50 mm |

| Rate of turn, rpm | 3 000 |

| Power supply | 3х380 V, 50 Hz |

| Max.flow rate, m3/h | 75 |

| Model | ADV 180 |

| Max.temperature, C | 90 |

| Max.viscosity, cPs | 500 |

| Max.diameter of solid inclusions, mm | 11 |

| Dimensions, mm | 170x380x1777 |

| Max. head, m | 35 |

| Length of immersed part | 1 000 |

| Material of flow channel | PP |

| Serial number of the pump | ADV |

| Country of Origin | Greece |

| PumpType | semi-submersible |

| Drive Type | electric |

| Installation Type | vertical |

| Availability of spare parts | Yes |

| Warranty, months | 12 |

| Logistics data: | |

| Weight, kg | 109 |