Catalog

Else categories

- Home

- Internal devices of columns and apparatuses

- Ceramic tower packing

- Ceramic Structured Packing

- Ceramic structured packing 550Y

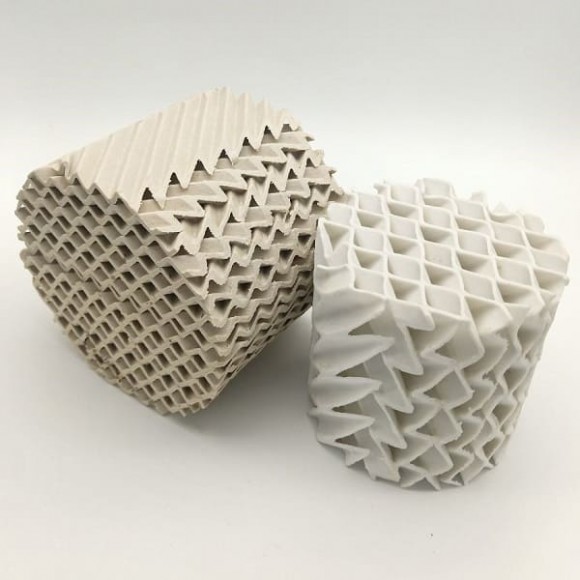

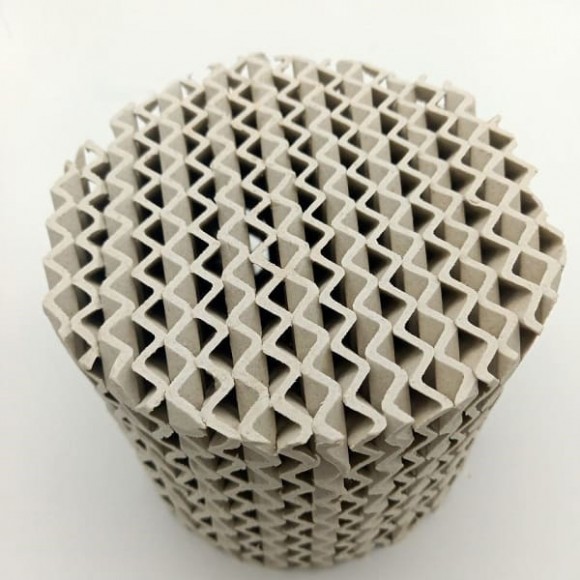

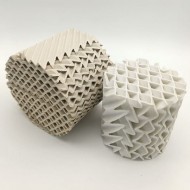

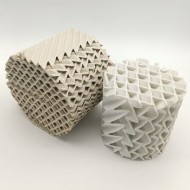

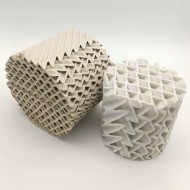

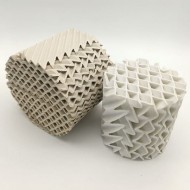

Ceramic structured packing 550Y

Overview

Ceramic structured packing 550Y

Keywords: ceramic structured packing, ceramic corrugated packing, ceramic lightweight packing, ceramic packing

Application ● Rectification of organic halide. ● rectification and absorption of some aggressive mixtures, which are certainly regulated by the pressure drop and the theoretical plate number. ● It is used in columns that contain a large amount of natural media that are used to absorb nitric acid and concentrated sulfuric acid, as well as for air purification in chemical plants. ● Operation in vacuum conditions at a lower absolute pressure of 100pa. ● Used in heat exchanger and cleaning, or as a catalyst carrier.

A ceramic structured packing consists of many units of the same geometric design. Corrugated sheets, placed in parallel, create cylindrical blocks called a column packing. This is a form of high-quality packing with separation efficiency several times higher than that of a bulk packing. They have the quality of a low pressure drop, increased operational elasticity, minimal reinforcing effect and maximum liquid treatment compared to a bulk packing.

Advantages

● High productivity The new column design can reduce the diameter, while the reconstruction of the old columns can significantly reduce the throughput.

● High separation efficiency. Since it has a much larger specific surface area in comparison with an irregular packing.

● Low pressure drop, which leads to a significant reduction in energy consumption.

● Greater flexibility and economies of scale are not obvious.

● Suitable for all column diameters.

● High corrosion resistance for alkalis and acids, especially to H2S, naphthenic acid and Cl -.

Application:

● Rectification of organic halide.

● Absorption of several aggressive mixtures, which are determined by the pressure drop and the theoretical plate number.

● It is used in some columns that contain a large amount of natural media, which are used to absorb nitric acid and concentrated sulfuric acid, as well as to purify the air in chemical plants.

● Operation in vacuum conditions at a lower absolute pressure of 100pa.

● Used in heat exchanger and purification, or as a catalyst carrier.

Chemical composition:

SiO2 ≥72%

Fe2O3≤0.5%

CaO ≤1.0%

Al2O3 ≥23%

MgO ≤1.0%

Other- 2%

Physical properties:

Specific weight (g/cm3) - 2.5

Water absorption (wt. %) ≤ 0.5

Acid resistance (wt. %) ≥99.5%

Incineration losses (wt. %) ≤ 5.0

Maximum operating temperature, °C - 800

Crushing strength (MPa) - ≥130%

Mohs hardness - ≥7

Specific surface area (m2 / m3) - 550

Bulk density, kg/m3 - 620

Void ratio, a - 74

Angle - 450

Pressure drop (mmHg/m) - 5.5

Theoretical number of plates, m-1 -5-6

Hydraulic diameter, mm - 6

Liquid load (m3/m2h) - 0.18-100

Max. coefficient, m/s (kg/m3)-1 - 1.4

Characteristics

| Producer | BTS Engineering |

| Material | Ceramics |

| Max.temperature, C | 800 |

| Nozzle type | Cтруктурована насадка (Structured Packing) |

| Pour density, kg/m3 | 620 |

| Specific surface area, m2/m3 | 550 |

| Void factor, % | 74 |

| Country of Origin | China |

| Analogue for | Ultimo Engineers, НКС DOLSIN, AMACS, MTE, Pall Ring Company, MACH Engineering LLC, Munters, Christy Catalytics, Koch-Glitsch |

| Logistics data: |