Catalog

Else categories

- Home

- Internal devices of columns and apparatuses

- Ceramic tower packing

- Ceramic Lessing rings

- Ceramic Lessing Rings 150 mm

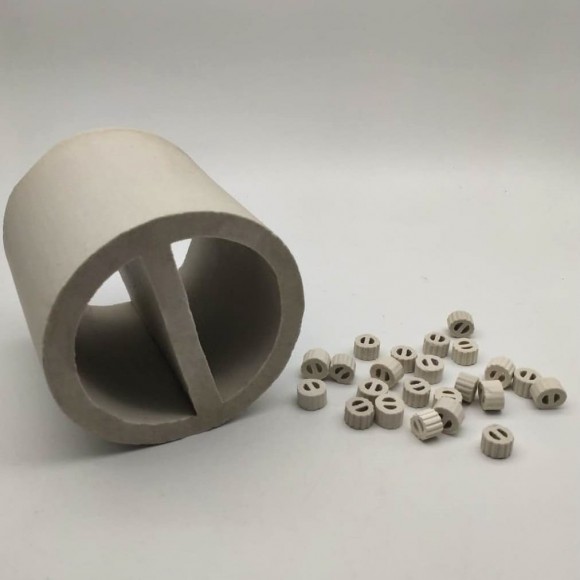

Ceramic Lessing Rings 150 mm

Documentation

Download instructions, catalog for Ceramic Lessing Rings 150 mm

Overview

Ceramic Lessing Rings 150 mm

Keywords: ceramic Lessing Rings, ceramic mini Lessing Ring

The ceramic Lessing ring is a packing made mainly of a rashig ring with partitions in gray to increase the surface and increase the transfer efficiency. It has a high density and excellent acid resistance, and also withstands corrosion by various inorganic acids, organic acids and organic solvents, except hydrofluoric acid.

Ceramic Lessing ring has excellent acid resistance and heat resistance, it can withstand high temperature, acid (except HF), alkali, salt and various organic solvents. It is widely used in the drying column, absorption column, cooling tower, log cabin and regeneration column, in the chemical industry, metallurgy, gas and environmental industries.

The ceramic Lessing ring can also be an important heat carrier used in a heat transfer system, a regenerative oxidizer (RTO) system.

Size, mm - 150

OD*ID*H*T , mm - 150*120*150*15

Weight, kg/m3 - 980

Quantity, pcs/m3 - 296

Area, m2/m3 - 60

Dry packing coefficient - 101

Characteristics

| Producer | BTS Engineering |

| Material | Ceramics |

| Thickness mm | 15 |

| Diameter, mm | 150 |

| Nozzle type | Керамические кольца Лессинга (Ceramic lessing ring) |

| Pour density, kg/m3 | 980 |

| Specific surface area, m2/m3 | 60 |

| Dimensions, mm | 150х120х150х15 |

| Quantity m.cubic | 296 |

| Country of Origin | China |

| Analogue for | AMACS, НКС DOLSIN, Ultimo Engineers, MTE, Pall Ring Company, MACH Engineering LLC, Munters, Christy Catalytics, Koch-Glitsch |

| Logistics data: |