Catalog

Else categories

- Home

- Internal devices of columns and apparatuses

- Plastic tower packingPlastic Packing NetBallLamella clarifiers tube settler plate separatorPlastic packing Q-packPlastic Pall ringsHeat-insulating balls for Sous Vide Plastic packing Tri PackSpiral packing Tellerette RingPlastic conjugate rings Filter Media MBBRPlastic Heilex ringsHollow floatation ballsABS filter nozzlePTFE Pall ringsPlastic hollow balls Polypropylene media Biopack 180 mm Bacterial FilterElastic solid packingPlastic Nu-Pack packingPlastic Lan Pack packingCooling tower infillsPlastic Structured PackingLiquid Surface Covering BallPolyhedral Hollow BallsPlastic Raschig ringsFloating Bio ballsPTFE Raschig ringsHDPE shade ballsInner Arc (VSP) RingsSnow Flower RingsPlastic Cascade Rings

- Filter Media MBBR

- Reactor with a moving layer of biofilm MBBR11-25x10 mm

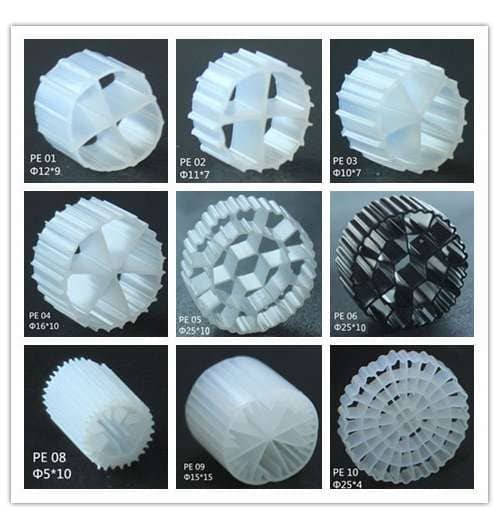

Reactor with a moving layer of biofilm MBBR11-25x10 mm

Documentation

Download instructions, catalog for Reactor with a moving layer of biofilm MBBR11-25x10 mm

Overview

Biofilm carrier MBBR is a new carrier of biological suspension, which modified polymetric material with the addition of a bio-enzyme, adapted for all types of microganism, for rapid growth and reproduction, in order to dissolve organic matter in water.

MBBR biofilm transfer process features high specific surface area, easy biofilm propagation, high denitrification, good hydrophilicity, high biological activity, and so on, It is widely used in MBBR biofilter for wastewater treatment, aquaculture farms, Koi filter media, etc.

Peculiarities of the product:

1. Self-cleaning through turbulence

2. Due to the turbulent motion of the biofilter in suspension, the filter material is self-cleaning and does not require maintenance. This allows the filter to achieve optimum efficiency without disrupting periodic maintenance, avoiding unnecessary loss of bacteria inside the filter. This ensures a stable low ammonia and nitrite content in the water.

3. The high surface area of these products results in a small physical area required for the biofiltration plant.

Thanks to the intensive mixing of a medium like Kaldnes, aerated medium is self-cleaning and maintenance-free. This allows the filter to achieve optimum efficiency. Periodic maintenance is not required, which prevents unnecessary loss of bacteria and subsequent surges of ammonia and nitrite in the system.

Required Carrier Volume - With good turbulence and aeration, a 50 liter filter is needed to deliver from 0.25 kg to 0.75 kg 40% protein per day.

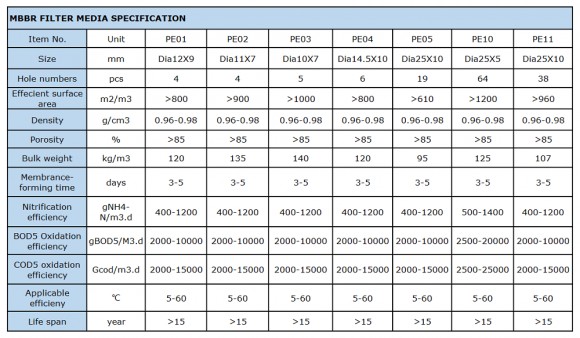

Size, mm - 25х10

The number of holes, pcs -38

Effective surface area, m2 /m3- > 980

Density, g/cm3 - 0.96-0.104

Porosity, % - > 85

Bulk weight, kg/m3 - 107

Formation time of membrane, days -3-5

Nitrification efficiency, gNH4 N/m3.d - 400-1206

Oxidation efficiency BOD5, gBOD5/M3.d - 2000-10006

Oxidation efficiency COD5, Gcod/m3.d- 2000-15006

Temperature, °С-5-60

Durability, years - >15

Characteristics

| Producer | BTS Engineering |

| Material | PP |

| Diameter, mm | 25 |

| Nozzle type | фильтрующий материал (MBR Filter Media) |

| Specific Gravity, g/cm3 | 0.96-0.104 |

| Pour density, kg/m3 | 107 |

| Specific surface area, m2/m3 | >960 |

| Number of holes | 38 |

| Dimensions, mm | 25х10 |

| Country of Origin | China |

| Analogue for | Ultimo Engineers, НКС DOLSIN, AMACS, MTE, Pall Ring Company, MACH Engineering LLC, Munters, Christy Catalytics, Koch-Glitsch |

| Logistics data: |