Catalog

Else categories

- Home

- Internal devices of columns and apparatuses

- Plastic tower packingPlastic Packing NetBallLamella clarifiers tube settler plate separatorPlastic packing Q-packPlastic Pall ringsHeat-insulating balls for Sous Vide Plastic packing Tri PackSpiral packing Tellerette RingPlastic conjugate rings Filter Media MBBRPlastic Heilex ringsHollow floatation ballsABS filter nozzlePTFE Pall ringsPlastic hollow balls Polypropylene media Biopack 180 mm Bacterial FilterElastic solid packingPlastic Nu-Pack packingPlastic Lan Pack packingCooling tower infillsPlastic Structured PackingLiquid Surface Covering BallPolyhedral Hollow BallsPlastic Raschig ringsFloating Bio ballsPTFE Raschig ringsHDPE shade ballsInner Arc (VSP) RingsSnow Flower RingsPlastic Cascade Rings

- Plastic Pall rings

- Pall Ring, d16 mm.

Pall Ring, d16 mm.

Documentation

Download instructions, catalog for Pall Ring, d16 mm.

Overview

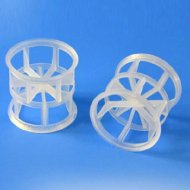

Pall rings are used extensively in both new and retrofit installations. Unlike Raschig rings, the walls of

our pall rings are open. The high percentage of free space maintains superior, uniform liquid

distribution. The ring's open space also provides gas and liquid full access to the ring's interior. The

interior of each ring has diametrical ribs, which provide structural strength as well as additional surface

area for gas-liquid contact.

Features: Pall Ring has a low pressure drop, large void space and high efficiency.

Applications: It is applicable to all kinds of separation, absorption equipment, atmospheric and vacuum

distillation unit, synthetic ammonia decarbonization and desulfurization systems, ethylbenzene

separation, isooctane, toluene separation, etc.

Ceramic Pall rings d16 mm – appointed for infilling of active volumes and apparatus to increase the intensity of heat and mass transfer process in equipment of chemical, petrochemical, oil refining industries and other fields of manufactory, water supply and canalization system, ammonia and mineral fertilizers production.

• Bulk density – 72 kg/m3

Ceramic Pall rings are irregular packing. Acid resistant ceramic packing are appointed for infilling of the column packing and other heat and transfer apparatus, that works under the temperature to 120 Celsius degrees for acidic media.

In comparison with Raschig rings, Pall rings have better absorbing capacity and reduced pressure drop, have better effectiveness of separation and the degree of wetting due to the perforated structure. Open structure of the packing ease the uniform loading pf packing and reduce and this reduces the losses.

Characteristics

| Producer | BTS Engineering |

| Material | PP |

| Diameter, mm | 16 |

| Operating temperature | -35-60 |

| Nozzle type | Pall Ring |

| Pour density, kg/m3 | 72 |

| Specific surface area, m2/m3 | 188 |

| Dimensions, mm | 16x16x1 |

| Void factor, % | 91,1 |

| Quantity m.cubic | 180 000 |

| Application | absorber, dehydration, calciner, desorber, distillation, rectification, water saturation, packed columns, gas cleaning |

| Analogue for | НКС DOLSIN, AMACS, Ultimo Engineers, MTE, Pall Ring Company, MACH Engineering LLC, Munters, Christy Catalytics, Koch-Glitsch |

| Logistics data: |