Catalog

Else categories

- Home

- Engineering services and equipmentVacuum evaporation plant Decanter centrifuges, separatorsCrushers for grinding cereal crops in the process of feed, flour, ethanol productionControl and measuring instruments, sensors, flow meters for production automationDesign, construction of a distillery, distillationSpiral shell and tube heat exchangerIndustrial dryersSolid fuel boilersEnzymes, alcohol yeast, antiseptics for the production of alcoholEnergy auditSteam industrial boilers

- Design, construction of a distillery, distillation

- Engineering services for the construction of a bioethanol plant

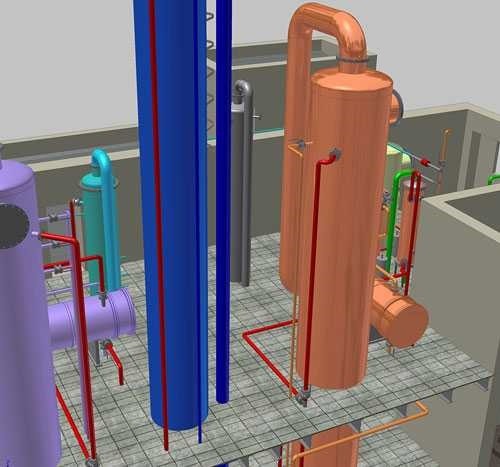

Engineering services for the construction of a bioethanol plant

Overview

Alcohol, bioethanol, construction of distilleries, bioethanol plants, alternative fuels production plants, ethanol production plants, design of distilleries, design of bioethanol production plants.

Our company offers a full range of works on the design and commissioning of plants for the production of alternative fuels, in particular bioethanol.

We have experience in designing plants with a capacity of 1,000 to 40,000 dal per day.

Corn, wheat, molasses and other types of starch-containing raw materials can be used as raw materials for the production of bioethanol.

BTS-ENGINEERING carries out reconstruction and design of plants of various sizes and specialties not only in Ukraine, but also in the CIS countries, the European Union and Africa.

BTS-ENGINEERING offers its clients comprehensive supervision and implementation of the entire turnkey project: from the design stage to the stage of commercial commissioning and subsequent after-sales service.

BTS-ENGINEERING offers turnkey construction services for the following plants:

Alcohol factories

Biofuel plants

BTS-ENGINEERING performs:

design and integrated design of the entire facility;

manufacture and supply of the entire range of necessary equipment;

process automation;

installation, supervision, commissioning and training of personnel.

This approach ensures the implementation of the project in a shorter time, a quick solution to emerging problems and issues, the ability to manufacture equipment strictly to the specific requirements of the customer, as well as other important advantages.

Based on advanced scientific research, the desire for innovation and deep knowledge in the alcohol industry, BTS-ENGINEERING specialists create unique personal solutions in the field of construction of distilleries that contribute to the success of our clients ' business.

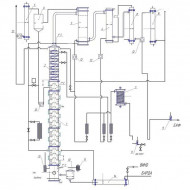

Characteristics

| Producer | BTS Engineering |

| Type | service |

| Consumption of hot steam, kg/liter (6 bar) | 2,5 – 4,0 |

| Electricity consumption, kW/liter | 0,5 |

| Artesian water, m3/liter | 0,002 |

| Consumption of circulating water, m3/liter (at the exit of the cooling tower 20˚C) | 0,2 |

| Consumption of fossil fuels, nm3/liter (on the example of natural gas) | 0,2 – 0,32 |

| Raw | grain crops, molasses, stream |

| Productivity, liter/day | 5000–100000 |

| Post-alcohol processing bards | Yes |

| The presence of ACS TP | Yes |

| Logistics data: |