Catalog

Else categories

- Home

- Engineering services and equipmentVacuum evaporation plant Decanter centrifuges, separatorsCrushers for grinding cereal crops in the process of feed, flour, ethanol productionControl and measuring instruments, sensors, flow meters for production automationDesign, construction of a distillery, distillationSpiral shell and tube heat exchangerIndustrial dryersSolid fuel boilersEnzymes, alcohol yeast, antiseptics for the production of alcoholEnergy auditSteam industrial boilers

- Design, construction of a distillery, distillation

- Plant for the production of carbon dioxide CO2 from bioethanol fermentation gases for 1000 kg/h

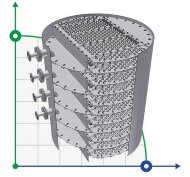

Plant for the production of carbon dioxide CO2 from bioethanol fermentation gases for 1000 kg/h

Documentation

Download instructions, catalog for Plant for the production of carbon dioxide CO2 from bioethanol fermentation gases for 1000 kg/h

Overview

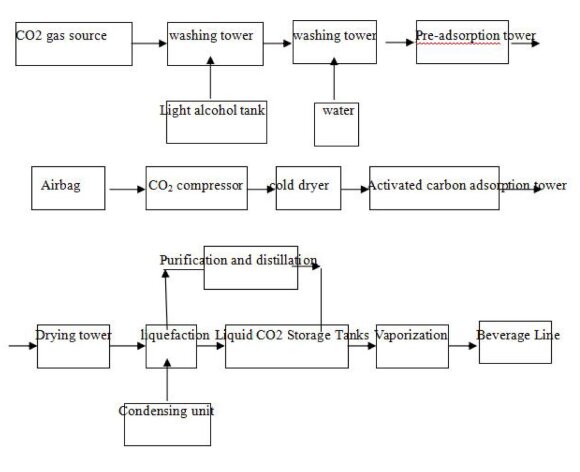

The carbon dioxide produced during fermentation first enters the dilute alcohol recovery system, which not only removes impurities such as alcohols and lipids contained in the CO2 gas, but also regenerates the alcohol. When the alcohol concentration in the circulating water tank reaches 3%, the dilute alcohol can be regenerated. The CO2 gas is then fed into a scrubber, where the alcohol, suspended particles in the gas, and impurities dissolved in the water are further washed out. After being washed with water twice, the carbon dioxide enters a two-stage parallel pre-adsorption column, which is used in turn. The pre-adsorption column is filled with high-efficiency activated carbon to further adsorb the organic molecules contained in the CO2 gas. At this stage, the relatively pure CO2 is compressed to 2.0MPa by a two-stage oil-free carbon dioxide compressor. To ensure the stable operation of the CO2 compressor, an air cushion is installed between the pre-adsorption column and the carbon dioxide compressor. The compressed gas is purified in the cold dryer, adsorption and drying columns, and the purified carbon dioxide is condensed into a liquid at a temperature of -20℃ in the carbon dioxide condenser; the cold source for the condenser is provided by the condensing unit. The liquid carbon dioxide is pumped into the gas purification column and reboiler through a pump and finally into the storage tank. When users sell carbon dioxide, they can fill it into a tanker truck with a filling pump or pump it into a cylinder with a CO2 filling pump.

Characteristics

| Productivity of the finished product, t/h | 1 |

| Producer | BTS Engineering |

| Pressure | 2 MPa |

| Logistics data: |