Catalog

Else categories

- Home

- Engineering services and equipmentVacuum evaporation plant Decanter centrifuges, separatorsCrushers for grinding cereal crops in the process of feed, flour, ethanol productionControl and measuring instruments, sensors, flow meters for production automationDesign, construction of a distillery, distillationSpiral shell and tube heat exchangerIndustrial dryersSolid fuel boilersEnzymes, alcohol yeast, antiseptics for the production of alcoholEnergy auditSteam industrial boilers

- Solid fuel boilers

- Retra-4M Combi boiler, 50kW with flare burner

Retra-4M Combi boiler, 50kW with flare burner

Overview

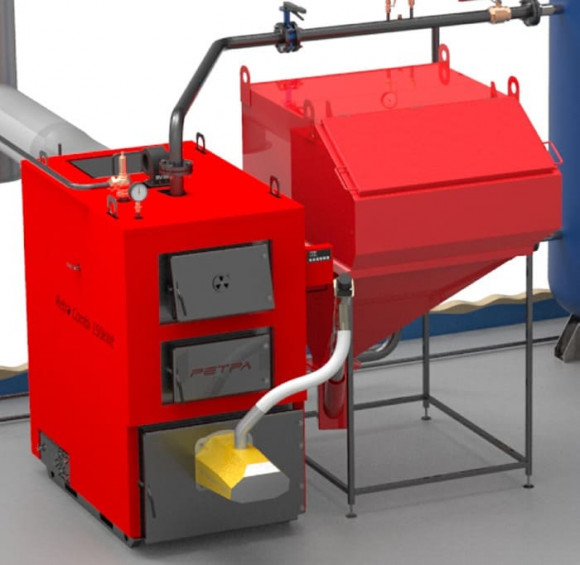

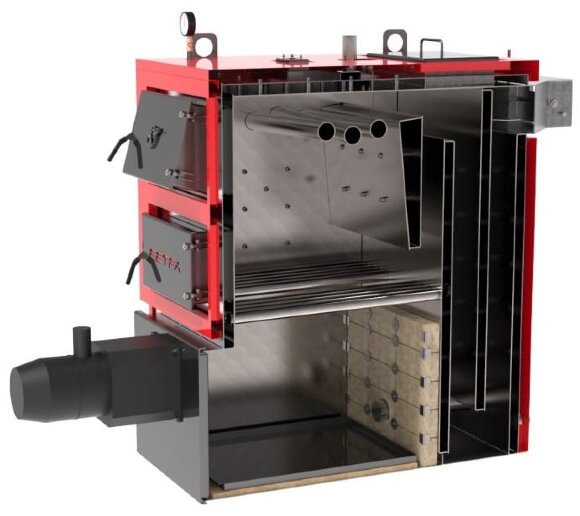

A flare burner is installed in the lower hatch of the boiler, into which fuel is mechanically supplied from the hopper. Fuel combustion takes place in the lower chamber. This automatic loading mode is designed for burning pellets (including agro-pellets, in a lined burner). The pellet burner torch is directed at the rear wall of the boiler furnace with lining. The process of automatic ignition, burning and cleaning of the burner is controlled by a multifunctional control unit. Mechanized fuel supply, Hopper and automation are supplied complete with a flare burner.

Boilers are designed to work in central water heating systems with forced (closed pressure heating system) or natural (open heating system) circulation of heat carrier for heat and hot water supply of residential buildings, dachas, industrial and warehouse premises, retail facilities, social and administrative buildings.

The Boilers are designed to operate in systems with an operating pressure of no more than 0.2 MPA (on request - 0.6 MPA) and a water temperature at the boiler outlet of no more than +95 °C.

Characteristics

| Furnace volume, L | 210 |

| Connection dimensions to the heating system | 2" |

| Upper combustion chamber size, mm (LxWxH | 690х500х630 |

| Connecting size of the safety valve | 3/4" |

| Overall dimensions of the boiler, mm (LxWxH) | 1660х760х1600 |

| Inner wall thickness of the heat exchanger, mm | 5 |

| Hopper capacity, M3 | 0,6 |

| Loading hatch neck size, mm (WxH) | 340х310 |

| Working pressure of the heat carrier, MPA, min / max | 0,1/0,25 |

| Water shirt volume, L | 175 |

| Boiler outlet water temperature, Max, °C | 95 |

| Vacuum behind the boiler, Pa, Max | 40 |

| Fuel type | pellets, agropellets |

| Water temperature at the boiler inlet, not less than, °C | 55 |

| Power consumption, W (220 V, 50 Hz), Max | 800 |

| Production period, days | ≥ 90 |

| Complete set | boiler RETRA-4M PLUS: torch burner OXI EVO (EVO-C), automation and flexible auger, bunker torch BF (pellets, agropellets) |

| Temperature of combustion products, Max, °C | 110-160 |

| Chimney pipe diameter, mm/height, m, not less | 200/7 |

| Heat exchanger area, m2 | 4,65 |

| Chimney outlet, mm | Ø200 |

| Boiler weight (without water), kg | 775 |

| Overall dimensions of the boiler with Hopper Assembly, mm (LxWxH) | 1660х1500х1670 |

| Producer | РЕТРА |

| Power capacity, kW | 50 |

| Serial number of the boiler | 4М Combi |

| Heating area, m2 (at a height of up to 3.5 m) | 500 |

| Country of Origin | Ukraine |

| Logistics data: |