- Home

- Industrial pumps

- Pumps by manufacturerACME PompeAQUABGS GeneralBTS EngineeringCalpedaDABDEBEMEMEC - dosing pumps, integrated disinfection systems, controllers, sensorsETATRON - metering pumpsETATRON - metering pumpsEUROAQUA - pumpsFLUIMAC - pumps for chemical liquidsGRUNDFOS - pumping equipmentGÜCÜM - vacuum pumping equipmentHYDRO-VACUUM - water ring vacuum pumps LIVERANI - screw, vortex, impeller, piston, gear pumps for pumping viscous liquidsM PUMPS - chemical pumps with magnetic driveNETTUNO - pumping systems for irrigation and wateringPEDROLLO - pumping equipmentROVATTI POMPE - pumps driven by a power take-off shaftROVER POMPE - pumps for pumping food liquids, juice, milk, emulsions, oil, wine, beer, wort, mashSAER - pumping equipmentSPERONI - pumping equipmentTECNICAPOMPE - pumping equipmentVENERONI - industrial pumps for watering, irrigation, lagoon mixersWILO – pumping equipment for water supply, wastewater disposal, circulation and pressure boostingYUY - sanitary pumps for viscous food products

- BTS EngineeringDrainage pumps WQDrainage pump WQK with cutting deviceCDLF Series Multistage PumpsCDLF Series Multistage Pump (Explosion Proof)Series Centrifugal Monoblock Pumps SM, BZPump with magnetic couplingMP-D, MP-HXPump with magnetic coupling MP-HXDWO open impeller pumpsJLM hot water pumpsIn-line pumps BTIHG, BGLH, BGWH stainless steel dry rotor pumpsPumps with dry rotor made of IRG cast ironStainless Steel GTP Centrifugal PumpsJL Heating Circulation Pumps

- CDLF Series Multistage Pump (Explosion Proof)

CDLF Series Multistage Pump (Explosion Proof)

Multistage vertical stainless steel pumps of the CDLF series in explosion-proof design Ex.

Designed for use in categorized rooms where there is a danger of explosion or fire and installation of equipment with motors in general industrial design is prohibited.

Explosion-proof equipment is always marked. Marking example: 1ExdellCT4

Description of marking:

1 - explosion protection level: explosion-proof equipment, in

which explosion protection is ensured both during normal operation and under recognized probable

damage, other than damage to explosion protection.

Ex is a sign indicating compliance

equipment to the requirements of GOST 12.2.020.

d - type of protection "d" - flameproof enclosure according to

GOST 22782.6.

e - type of explosion protection "e" according to GOST 22782.7.

IС - subgroup sign

electrical equipment corresponding to the category of explosive mixtures for which the equipment is

explosion-proof.

The flow part of the pumps of this series is made of steel grades AISI 304, AISI 316L (acid-resistant stainless steel).

The use of these steel grades allows the use of such pumps for pumping liquids containing acids and alkalis, washing solutions, hot and cold water, luther, phlegm, shoulder straps, alcohol, solvent, epurates, sivukha, as well as many other liquids.

The working cavity of the pump is sealed due to the use of a special cartridge, chemically resistant seals. The pump is driven through a coupling connecting the shaft and the electric motor. Using the coupling simplifies assembly and disassembly of the pump for maintenance. Vertical pump design prevents the motor from flooding when the mechanical seal is leaking, and the linear arrangement of the suction and pressure connection simplifies the installation and connection process.

- Explosion-proof pumps are most in demand in such industries as:

- alcohol and bioethanol production;

- chemical industry;

- oil and gas industry;

- fire extinguishing systems.

Multistage pumps

Applications

- Water supply: water filtration and its supply through water supply networks, pressure increase in plumbing and in multi-storey buildings.

- In industry: process water, flushing system, flushing system under pressure, fire extinguishing system.

- Industrial water supply: cooling and air conditioning system, water supply to boiler, condensation system, production plants, work with acids and alkalis.

- Water treatment: ultrafiltration system, reverse osmosis system, distillation system, separation, use in pools.

- Irrigation: agricultural land irrigation, spray irrigation, drip irrigation irrigation, etc.

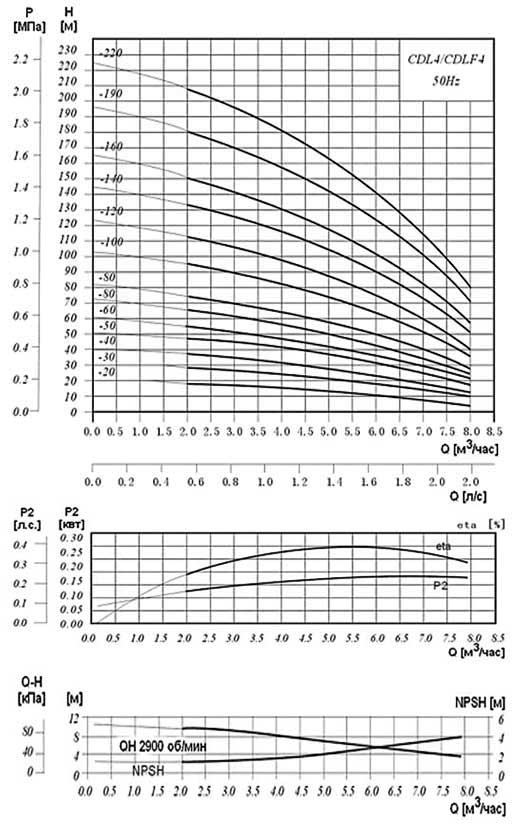

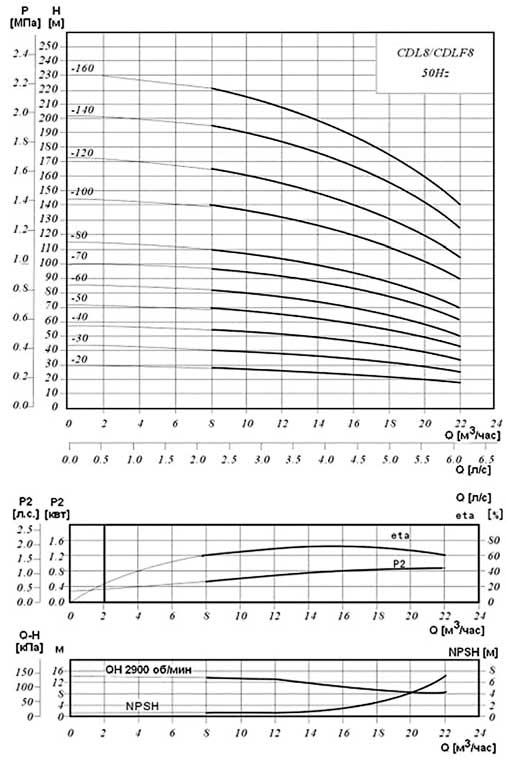

Capacity diagrams for CDLF pumps

Materials

| No. p/p |

Name | Material | AISI/ASTM | Scheme |

| 1 | Electric motor | - | Standard/Ex |  |

| 2 | Housing | Cast iron | ASTM25B | |

| 3 | Mechanical seal | Stainless steel | AISI304/316L | |

| 4 | Water outlet impeller | Stainless steel | AISI304/316L | |

| 5 | The impeller pumps | Stainless steel | AISI304/316L | |

| 6 | Support impeller | Stainless steel | AISI304/316L | |

| 7 | Pressurized fluid supply device | Stainless steel | AISI304/316L | |

| 8 | Suction and discharge connection of the pump | Stainless steel | AISI304/316L | |

| 9 | Support frame | Cast iron | ASTM25B | |

| 10 | Sleeve on the shaft | Durable alloy | YG8 | |

| 11 | Working wheel | Stainless steel | AISI304/316L | |

| 12 | Shaft | Stainless steel | AISI316 | |

| 13 | Disconnecting Impeller Coupling | Stainless steel | AISI304/316L | |

| 14 | Pump casing | Stainless steel | AISI304/316L | |

| 15 | Clutch | Carbon steel | - | |

| 16 | Seals | FPM/VITON | - |

CDLF Pump Specifications

| Model | 50Hz CDLF 2 | 50Hz CDLF four | 50Hz CDLF 8 | 50 Hz CDLF 16 |

| Nominal capacity (m³/hr) | 2 | 4 | 8 | 16 |

| Capacity range (m³/hr) | 1-3.5 | 1.5-8 | 6-12 | 8-22 |

| Rotation speed (rpm) | 2900 | 2900 | 2900 | 2900 |

| Engine power (kW) | 0.37-3 | 0.37-4 | 0.75-7.5 | 2.5-15 |

| Head (m) | 15-195 | 16-176 | 12-196 | 22-189 |

| Temperature range (°С) | -15 °С...+ 120 °С | -15 °С...+ 120 °С | -15 °С...+ 120 °С | -15 °С...+ 120 °С |

| Maximum efficiency (%) | 46 | 59 | 64 | 71 |

| Maximum pressure (bar) | 23 | 22 | 22 | 22 |

| Outside temperature | up to + 40 °С | up to + 40 °С | up to + 40 °С | up to + 40 °С |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 8 |

| Feed height, m | 95 |

| Power capacity, kW | 2,2 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 12 |

| Feed height, m | 71 |

| Power capacity, kW | 3 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 22 |

| Feed height, m | 68 |

| Power capacity, kW | 5,5 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 22 |

| Feed height, m | 82 |

| Power capacity, kW | 5,5 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 22 |

| Feed height, m | 54 |

| Power capacity, kW | 4 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 3.5 |

| Feed height, m | 71 |

| Power capacity, kW | 1,1 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 8 |

| Feed height, m | 29 |

| Power capacity, kW | 0,55 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 8 |

| Feed height, m | 57 |

| Power capacity, kW | 1,1 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 8 |

| Feed height, m | 67 |

| Power capacity, kW | 1,5 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 12 |

| Feed height, m | 51 |

| Power capacity, kW | 2,2 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 12 |

| Feed height, m | 61 |

| Power capacity, kW | 2,2 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 3.5 |

| Feed height, m | 45 |

| Power capacity, kW | 0,75 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 3.5 |

| Feed height, m | 89 |

| Power capacity, kW | 1,1 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 3.5 |

| Feed height, m | 97 |

| Power capacity, kW | 1,1 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 3.5 |

| Feed height, m | 53 |

| Power capacity, kW | 0,75 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 8 |

| Feed height, m | 38 |

| Power capacity, kW | 0,75 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 8 |

| Feed height, m | 48 |

| Power capacity, kW | 1,1 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 8 |

| Feed height, m | 86 |

| Power capacity, kW | 2,2 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 12 |

| Feed height, m | 31 |

| Power capacity, kW | 1 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 12 |

| Feed height, m | 41 |

| Power capacity, kW | 1,5 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 12 |

| Feed height, m | 81 |

| Power capacity, kW | 3 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 22 |

| Feed height, m | 41 |

| Power capacity, kW | 3 |

| Material | AISI 316 stainless steel |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 3.5 |

| Feed height, m | 36 |

| Power capacity, kW | 0,55 |

| Material | AISI 316 stainless steel |