- Home

- Industrial pumps

- Pumps by manufacturer

- BTS EngineeringDrainage pumps WQDrainage pump WQK with cutting deviceCDLF Series Multistage PumpsCDLF Series Multistage Pump (Explosion Proof)Series Centrifugal Monoblock Pumps SM, BZPump with magnetic couplingMP-D, MP-HXPump with magnetic coupling MP-HXDWO open impeller pumpsJLM hot water pumpsIn-line pumps BTIHG, BGLH, BGWH stainless steel dry rotor pumpsPumps with dry rotor made of IRG cast ironStainless Steel GTP Centrifugal PumpsJL Heating Circulation Pumps

- Drainage pumps WQ

Drainage pumps WQ

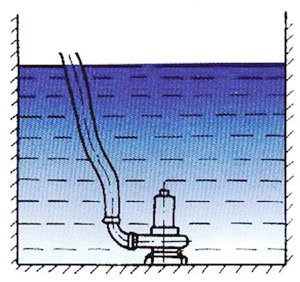

Drainage pumps are used to pump clean or contaminated water from drainage wells, pits, pools and reservoirs. These pumps can be installed for permanent stationary operation or carried from place to place.

These pumps are of10 equipped with a float switch that starts and stops them in depending on the water level (in addition, modern models of leading pump manufacturers are supplied with protection against overheating and dry running). The portable WQ pumps are also designed for pumping water when underflooding, for use in engineering systems of agricultural and industrial enterprises and etc.

Description

Pumping process water free of solid particles and fibers.

Drainage pumps WQ - pumps are designed to pump drainage and groundwater from systems located in private residential buildings or backyards, in agricultural and small industrial enterprises, etc.

- Consumption: from 10 to 300 m³/hour.

- Head: from 7 to 35 m.

- Power: from 0.75 to 22 kW.

Characteristics

- The pumps are compact, do not create a lot of noise, do not consume a lot of energy, are available for main10ance and repair;

- The ability to provide control over the water level, electric current, overload and overheating of the engine;

- Depending on the level of runoff water, the level float switch can automatically turn on or off pump;

- The pump head is regulated until the maximum performance is reached, which does not harm the engine;

- There are two ways to install: installation with fixed connection and Mobile installation.

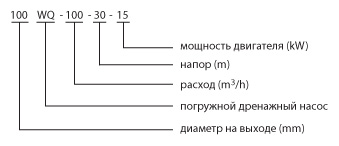

WQ50-10-4

200WQ300-15-22

Application

Drainage pumps are used in any wastewater treatment system that is required in municipal services, chemical plants, mines and quarries, cement production, etc.

- Pumping drainage and surface water;

- Groundwater pumping;

- Pumping process water free of solid particles and fibers.

Working conditions

Normal and long-term operation of the pump is ensured under the following conditions:

- The average temperature should not exceed + 40 °C;

- Average density of liquid that is pumped 1000 ... 1200 kg /m3;

- Frequency 50 Hz, voltage 380 V, permissible deviation of supply voltage within ± 5% of nominal.

Main settings

Performance charts

Drainage pumps WQ

| Model | Consumption (m3/hour) |

Head (m) |

Power (kw) |

Speed (rpm) |

Diameter (mm) |

Current (IN) |

Frequency (Hz) |

The weight (kg) |

| 50WQ10-10-0.75 | 10 | 10 | 0.75 | 2900 | 50 | 380 | 50 | 21 |

| 50WQ15-7-0.1 | 15 | 7 | 0.1 | 50 | 26 | |||

| 50WQ20-15-1.5 | 20 | 15 | 1.5 | 50 | 55 | |||

| 65WQ25-10-1.5 | 25 | 10 | 1.5 | 65 | 58 | |||

| 50WQ15-25-2.2 | 15 | 25 | 2.2 | 50 | 56 | |||

| 65WQ25-15-2.2 | 25 | 15 | 2.2 | 65 | 60 | |||

| 65WQ37-13-3 | 37 | 13 | 3 | 65 | 70 | |||

| 85WQ43-13-3 | 43 | 13 | 3 | 80 | 85 | |||

| 65WQ25-30-4 | 25 | 30 | 4 | 65 | 85 | |||

| 80WQ40-15-4 | 40 | 15 | 4 | 80 | 90 | |||

| 100WQ110-10-5.5 | 110 | 10 | 5.5 | 1450 | 100 | 155 | ||

| 100WQ100-15-7.5 | 100 | 15 | 7.5 | 100 | 170 | |||

| 100WQ100-25-11 | 100 | 25 | 11 | 100 | 65 | |||

| 200WQ300-7-11 | 300 | 7 | 11 | 200 | 73 | |||

| 100WQ100-30-15 | 100 | 30 | 15 | 100 | 300 | |||

| 150WQ180-15-15 | 180 | 15 | 15 | 150 | 280 | |||

| 200WQ250-15-15 | 250 | 15 | 15 | 200 | 400 | |||

| 100WQ100-35-18.5 | 100 | 35 | 18.5 | 100 | 380 | |||

| 150WQ180-20-18.5 | 180 | 20 | 18.5 | 150 | 400 | |||

| 200WQ250-15-18.5 | 250 | 15 | 18.5 | 200 | 500 | |||

| 150WQ180-25-22 | 180 | 25 | 22 | 150 | 430 | |||

| 200WQ300-15-22 | 300 | 15 | 22 | 200 | 550 |

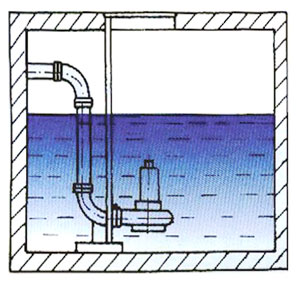

Installation of the drainage pump WQ

Installation with fixed connection

Mobile installation

| Producer | BTS Engineering |

| Pump capacity, m3/h | 20 |

| Feed height, m | 15 |

| Power capacity, kW | 1,5 |

| Material | cast iron |

| Producer | BTS Engineering |

| Power capacity, kW | 11 |

| Material | cast iron |

| Output pipe diameter | DN50 |

| Rate of turn, rpm | 2 900 |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 30 |

| Feed height, m | 60 |

| Power capacity, kW | 15 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 25 |

| Feed height, m | 30 |

| Power capacity, kW | 5,5 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 300 |

| Power capacity, kW | 22 |

| Material | cast iron |

| Output pipe diameter | DN200 |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 30 |

| Feed height, m | 25 |

| Power capacity, kW | 4 |

| Output pipe diameter | DN80 |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 80 |

| Feed height, m | 30 |

| Power capacity, kW | 15 |

| Output pipe diameter | DN100 |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 100 |

| Feed height, m | 25 |

| Power capacity, kW | 11 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 15 |

| Feed height, m | 15 |

| Power capacity, kW | 2,2 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 180 |

| Feed height, m | 20 |

| Power capacity, kW | 18,5 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 250 |

| Feed height, m | 15 |

| Power capacity, kW | 22 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 40 |

| Feed height, m | 15 |

| Power capacity, kW | 4 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 25 |

| Feed height, m | 10 |

| Power capacity, kW | 2,2 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 25 |

| Feed height, m | 7 |

| Power capacity, kW | 1,5 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 35 |

| Feed height, m | 10 |

| Power capacity, kW | 3 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 70 |

| Feed height, m | 10 |

| Power capacity, kW | 5,5 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 180 |

| Feed height, m | 25 |

| Power capacity, kW | 22 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 250 |

| Power capacity, kW | 15 |

| Material | cast iron |

| Output pipe diameter | DN200 |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 50 |

| Power capacity, kW | 4 |

| Material | cast iron |

| Output pipe diameter | DN100 |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 600 |

| Feed height, m | 12 |

| Power capacity, kW | 37 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 2200 |

| Feed height, m | 5 |

| Power capacity, kW | 55 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 1300 |

| Feed height, m | 31 |

| Power capacity, kW | 90 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 25 |

| Feed height, m | 18 |

| Power capacity, kW | 3 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 40 |

| Feed height, m | 28 |

| Power capacity, kW | 7,5 |

| Material | cast iron |