- Home

- Industrial pumps

- Pumps by manufacturer

- BTS EngineeringDrainage pumps WQDrainage pump WQK with cutting deviceCDLF Series Multistage PumpsCDLF Series Multistage Pump (Explosion Proof)Series Centrifugal Monoblock Pumps SM, BZPump with magnetic couplingMP-D, MP-HXPump with magnetic coupling MP-HXDWO open impeller pumpsJLM hot water pumpsIn-line pumps BTIHG, BGLH, BGWH stainless steel dry rotor pumpsPumps with dry rotor made of IRG cast ironStainless Steel GTP Centrifugal PumpsJL Heating Circulation Pumps

- Drainage pump WQK with cutting device

Drainage pump WQK with cutting device

Drainage pumps WQK series with grinderAre centrifugal pumps equipped with system for grinding coarse particles and fibers, installed at the suction. The pumps are not affected clogging and congestion.

The advantages of the pumps are reliability, high performance, low energy consumption, and the cutting mechanism provides the ability to pump media containing paper and other long-fiber particles.

The grinder pump is ideal for use in systems for pumping fluids from remote areas. zones, detached buildings, utilities, etc.

This type of pump is not well suited for pumping liquids with a high suspended sand content.

Characteristic

- Drainage pumps equipped with cutting mechanism,can cut waste such as cloth, paper, etc .;

- Closed impeller with double impeller;

- The rotor shaft has a high wear resistance and corrosion;

- Double mechanical seal increases operational reliability pump;

- The pumps are compact, easy to operate and service.

Drainage pump WQK anti-clogging design(cutting mechanism) , widely used in industry, agricultural irrigation, mining, construction, utilities, etc. They are ideal for pumping dirty water, waste water from long-fiber particles, fecal waters.

Working conditions

Normal and long-term operation of the pump is ensured under the following conditions:

- The average temperature should not exceed + 40 °С;

- The average density of the liquid, which is pumped over 1000 ... 1200 kg/m3;

- Frequency 50 Hz, voltage 380 V;

- Permissible deviation of supply voltage within ± 10% of nominal.

Main settings

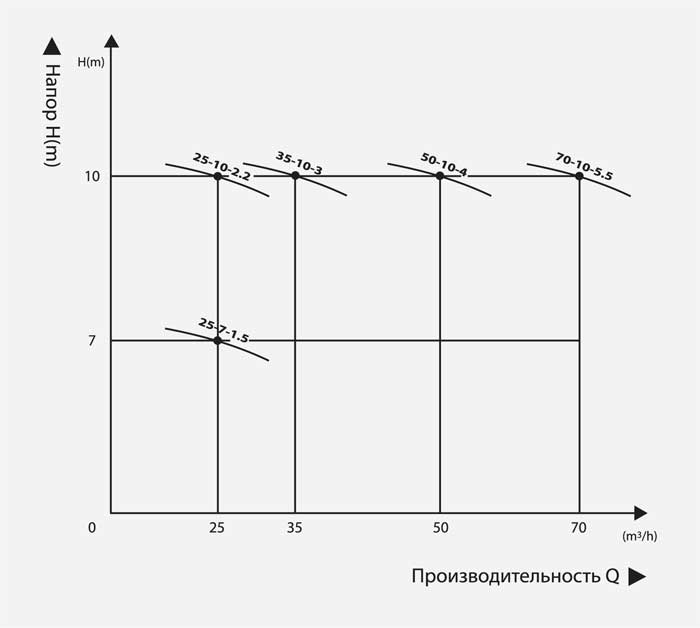

Performance diagram

| Model | Voltage (V /Hz) |

Diameter (mm) |

Consumption (m3/hour) |

Head (m) |

Power (kw) |

Speed (rpm) |

| WQK 25-7-1.5 | 380/50 | 50 | 25 | 7 | 1.5 | 2860 |

| WQK 25-10-2.2 | 380/50 | 50 | 25 | 10 | 2.2 | 2860 |

| WQK 35-10-3 | 380/50 | 70 | 35 | 10 | 3 | 2860 |

| WQK 50-10-4 | 380/50 | 100 | 50 | 10 | 4 | 2860 |

| WQK 70-10-5.5 | 380/50 | 166 | 70 | 10 | 5.5 | 2860 |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 30 |

| Feed height, m | 25 |

| Power capacity, kW | 4 |

| Output pipe diameter | DN80 |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 80 |

| Feed height, m | 30 |

| Power capacity, kW | 15 |

| Output pipe diameter | DN100 |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 25 |

| Feed height, m | 10 |

| Power capacity, kW | 2,2 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 25 |

| Feed height, m | 7 |

| Power capacity, kW | 1,5 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 35 |

| Feed height, m | 10 |

| Power capacity, kW | 3 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 70 |

| Feed height, m | 10 |

| Power capacity, kW | 5,5 |

| Material | cast iron |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 50 |

| Power capacity, kW | 4 |

| Material | cast iron |

| Output pipe diameter | DN100 |