- Home

- Industrial pumps

- Pumps by manufacturer

- WILOWilo-Drain TSW stainless steel submersible pumpWilo-Drain TMW submersible pump for drainage water drainagePB booster pumpMVI vertical high pressure pumps HELIX FIRST, MVIHorizontal high pressure pumps MEDANA, MHIWell pumps Wilo-Sub TWI 5, TWI 5-SE, TWI 5-SE PNPWILO CronoNorm NL cantilever pumpsWilo-DrainLift KH, TMP Pressure plants for wastewater disposalPumping station Wilo-Jet HWJ with a hydraulic accuHigh pressure glandless pumps MVISSubmersible pumps Wilo-Drain MTS for wastewater diSelf-priming centrifugal pumps Wilo-Jet WJFire extinguishing system Wilo-SiFire ENSpecial IPH pumps for superheated water and thermal oilWilo-FLA-2 pressure boosting systemSewage pumps Wilo EMU FAWILO TOP-S Glandless Circulation PumpsCirculation pumps for heating systems and underflo

- Pumping station Wilo-Jet HWJ with a hydraulic accu

Pumping station Wilo-Jet HWJ with a hydraulic accu

Application

Self-priming stations Wilo-Jet HWJ used for automatic water supply at home and cottages from a shallow reservoir if the water is at a depth of no more than 8 m.

Wilo-Jet HWJ automatic pumping stations are units with a pump, designed to supply water and maintain the required pressure in the system.

The pumping station includes a self-priming pump capable of supplying water from the depth, as well as a relay pressure and pressure tank.

- Water supply systems.

- Watering.

- Irrigation and irrigation.

- Water supply from wells and deeply located reservoirs.

Designation

Example: HWJ 301 60L 1 ~

H Pump system with diaphragm pressure vessel

WJ Wilo-Jet pumps

3 Nominal flow rate Q in m3/h at optimum efficiency

01 Number of pump stages

60L Tank size

1 ~Single phase current, 1 ~ 220 V, 50 Hz

Specifications

- Stainless steel construction: durable and corrosion resistant.

- Self-priming up to 8 m.

- Maximum flow rate max. 4.5 m3/hour.

- Built-in motor protection.

- Mains connection 1 ~ 220 V.

- Liquid temperature max. from +5 °C to +35 °C.

- Working pressure max. 6 bar.

Wilo-Jet HWJ range

| Pump |

Power [kW] |

Consumption [m3/hour] |

Pressure [m] |

The weight [kg] |

| HWJ 201 1 ~ |

0.8 | 1.7 | 30 | 16.9 |

| HWJ 301 1 ~ |

1.1 | 2.0 | 34 | 20.4 |

| HWJ 401 1 ~ |

1.3 | 3.0 | 30 | 29.8 |

| HWJ 301 60L 1 ~ |

1.1 | 2.0 | 34 | 25.2 |

| HWJ 401 60L 1 ~ |

1.3 | 3.0 | 30 | 34.4 |

1 ~ single-phase pump - 220 V

Device and principle of operation

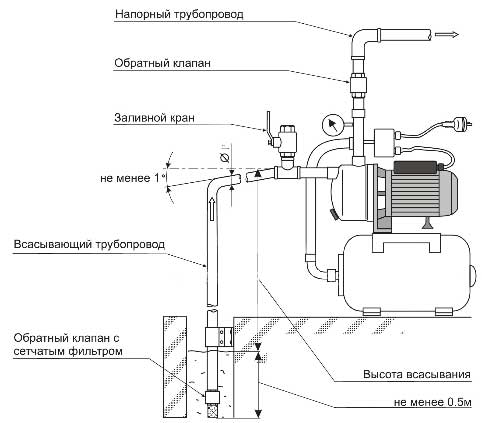

Automatic pumping station (fig.) consists of a surface centrifugal self-priming electric pump, accumulator, pressure switch, pressure gauge and connecting fittings. The electric pump consists of the pumping part and the electric motor, which are mounted on the adapter flange.

- The pumping part is a cast iron or stainless steel casing, an impeller made of brass and built-in ejector.

- Electric motor - asynchronous, closed type with external ventilation. Installed on the electric motor terminal box, which contains the capacitor and terminal blocks for connecting the electric motor to power cable.

- The hydraulic accumulator is designed to store water under pressure. Consists of a reservoir with a replaceable membrane made of food-grade rubber and has a pneumatic valve for air injection.

- The pressure switch serves to automatically turn on and off the pump, depending on the water pressure in system.

- The pressure gauge is designed for visual control of the pressure in the system.

Installation and commissioning of pumping stations

Before installing the electric pump (automatic pumping station), it is necessary to choose the correct installation location. It is recommended to install the electric pump either indoors or outdoors on a horizontal platform, in well ventilated and protected from bad weather.

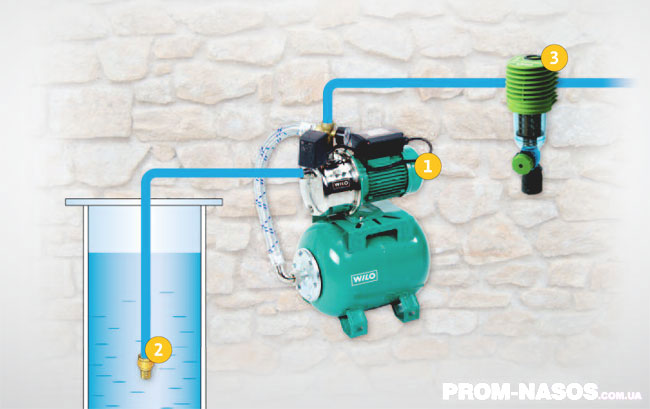

Automatic water supply to the house from a well using a pumping station Wilo-Jet HWJ

- Pump station HWJ with pump WJ.

- Suction hose kit.

- Backwash filter.