- Home

- Industrial pumps

- Pumps by typeBarrel pumps Vacuum pumpsVertical semi-submersible pumpsScrew pumpsVortex pumpsHermetic pumpsDispersant-emulsifier, homogenizerDosing pumpsImpeller pumpsSewer stationsCantilever pumpsLobe pumpsDiaphragm pumpsPneumatic diaphragm submersible pumpsMultistage pumpsCast iron monobloc pumpsMotor pumpsMotor diaphragm pumpsEx ATEX pumpPTO driven pumpDouble inlet pumpsInline pumpsGlandless pumpsAxial pumpsPeristaltic pumpsRotary vane pumpsPlunger pumpsSemi-submersible fecal, drainage pumpSubmersible drainage and fecal pumpsSubmersible slurry pumpsPiston pumpsRoller pumps Self-priming centrifgual pumpSanitary, hygienic pumpsBorehole pumpsSolenoid pump dispenserWater supply and fire extinguishing stationsChemical magnetic pumpsCentrifugal pumpsGear pumpsIndustrial hose peristaltic pumps

- Barrel pumps

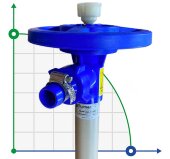

- Drum pumps Ex (explosion-proof electric motor)

Drum pumps Ex (explosion-proof electric motor)

Engine Properties:

- Motor model meaning: Explosion-proof motor.

- Voltage: 220 V.

- Speed: 12000 rpm.

- Frequency: 50-60 Hz.

- Power: 880 W

Drum pumps are designed for pumping various types of liquids from cans, barrels and euro cubes. Drum pumps are made from a variety of materials such as stainless steel, aluminum, PVC, polypropylene, etc.

The supply of acids, alkalis and reagents in drums and IBCs has become common practice. The specified container is most often reversible, which means that it must be quickly and carefully emptied and returned to the sender. As containers with a bottom drain became banned in many countries due to the risk of spillage, the only way to pump liquid was to use a hole in the lid. The most suitable equipment for this work was barrel pumps.

Drum pumps for chemically active liquids caustic sodium, acetic, nitric, hydrofluoric acids, hydrochloric acid, nitric acid and others.

Drum pumps handle food additives, foodstuffs, molasses, thickeners, flavors, enzymes, liquid concentrates and ingredients. In industry: pumping and unloading reagents and liquids from plastic containers, euro cubes and barrels.

Drum pumps also pump petroleum products, solvents, hardeners and other components.

| Producer | BTS Engineering |

| Material | AL |

| Output pipe diameter | 25 mm |

| Max.temperature, C | 1 000 |

| Height, mm | 1 000 |

| Producer | BTS Engineering |

| Material | AL |

| Output pipe diameter | 25 mm |

| Max.temperature, C | 1 000 |

| Height, mm | 1 200 |

| Producer | BTS Engineering |

| Material | AISI 316L |

| Output pipe diameter | 25 mm |

| Max.temperature, C | 100 |

| Height, mm | 1 200 |

| Producer | BTS Engineering |

| Material | AISI 316L |

| Output pipe diameter | 25 mm |

| Max.temperature, C | 100 |

| Height, mm | 1 200 |

| Producer | FLUIMAC |

| Material | PP |

| Max.temperature, C | 50 |

| Height, mm | 1 200 |

| Length, mm | 1 200 |

| Producer | BTS Engineering |

| Material | AISI 316L |

| Output pipe diameter | 25 mm |

| Max.temperature, C | 100 |

| Height, mm | 1 000 |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 12 |

| Material | AL |

| Input pipe diameter | 41 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 12 |

| Material | AISI 304 stainless steel |

| Input pipe diameter | 42 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 12 |

| Material | AISI 316L |

| Input pipe diameter | 42 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 12 |

| Material | PP |

| Input pipe diameter | 41 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 12 |

| Material | PVDF |

| Input pipe diameter | 41 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 12 |

| Material | PTFE |

| Input pipe diameter | 50 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 30 |

| Material | AL |

| Input pipe diameter | 41 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 30 |

| Material | AISI 304 stainless steel |

| Input pipe diameter | 42 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 30 |

| Material | AISI 316L |

| Input pipe diameter | 42 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 30 |

| Material | PP |

| Input pipe diameter | 41 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 30 |

| Material | PVDF |

| Input pipe diameter | 41 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 30 |

| Material | PTFE |

| Input pipe diameter | 50 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 12 |

| Material | AL |

| Input pipe diameter | 41 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 12 |

| Material | AISI 304 stainless steel |

| Input pipe diameter | 42 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 12 |

| Material | AISI 316L |

| Input pipe diameter | 42 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 12 |

| Material | PP |

| Input pipe diameter | 41 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 12 |

| Material | PVDF |

| Input pipe diameter | 41 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 12 |

| Material | PTFE |

| Input pipe diameter | 50 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 30 |

| Material | AL |

| Input pipe diameter | 41 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 30 |

| Material | AISI 304 stainless steel |

| Input pipe diameter | 42 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 30 |

| Material | AISI 316L |

| Input pipe diameter | 42 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 30 |

| Material | PP |

| Input pipe diameter | 41 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 30 |

| Material | PVDF |

| Input pipe diameter | 41 mm |

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Feed height, m | 30 |

| Material | PTFE |

| Input pipe diameter | 50 mm |