- Home

- Industrial pumps

- Pumps by industry, purposeThe barrier pump of the refinery of pollutantsHigh temperature pumps +400°CCryogenic pumps for liquids -196°CEx pump for biogas plantsATEX gas intake well filtrate pumping pumpBiogas Intake and Utilization Filtrate PumpWater pumps of producing wellsPumps for unloading and loading railway tanksPumps for lowering the flood water levelBilge pump Ex ATEX certificatePumps for agriculture and irrigationPumps for the food industryHydroponics (Fertilizer Dosing Systems)Pumps for woodworkingChemical pumpsPumps for housing and communal servicesEvaporator pumpsSteam boiler pumps, feed pumpsIndustrial pumps

- Cryogenic pumps for liquids -196°C

Cryogenic pumps for liquids -196°C

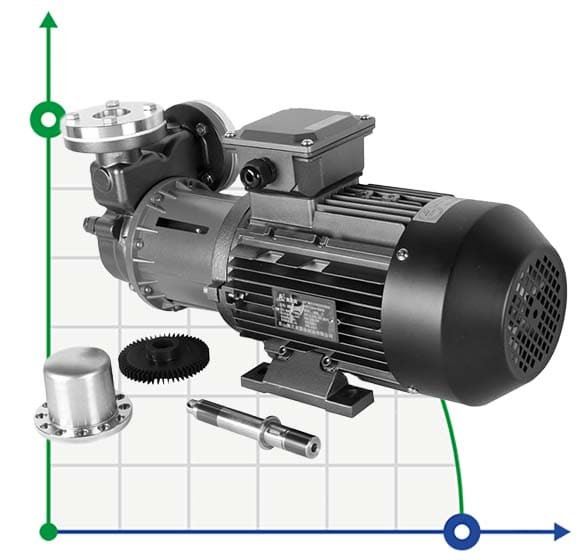

Cryogenic liquid pumps are pumps used to pump cryogenic liquids. This can be liquid oxygen, liquefied natural gas, argon, or other similar liquids. The devices are characterized by maximum tightness and reliability due to the use of leading modern technologies in the design, as well as solid high-quality materials.

Such pumps are usually used in industrial production, where it is necessary to transport cryogenic liquids. Also, cryogenic pumps are often found in the manufacture of various pharmaceutical products.

Types of cryogenic pumps for liquids

Depending on the functionality and design, there are:

Centrifugal cryogenic pumps

They are used to transport liquids from built-in tanks to mobile tanks or barrels. Such pumps can be installed both on non-moving platforms and on vehicles that are used for transporting cryogenic liquids.

Reciprocating cryogenic pumps

Pumps that are used to pump liquids into specially designated tanks. Such pumps are installed in open areas near liquid tanks. Reciprocating cryogenic pumps are adaptive and can additionally be equipped with a variety of sensors for monitoring temperature, cooling and pressure drops in the system.

Submersible cryogenic pumps

A type of pump that is placed directly in a cryogenic liquid. Completely sealed and made of reliable materials. They are characterized by high power and can be used for a long time without stopping or in situations of constant start / stop of the device.

They are most often used to pump liquefied gases or load or unload tanks and any other containers for storing cryogenic liquids. There are single-section, two-section and four-section cryogenic pumps.

Advantages and features of cryogenic liquid pumps

You need to buy a cryogenic pump for liquids for many reasons. It has many advantages and is used during the need for pumping liquids of this type.

- Such a pump is practically maintenance - free, and the pump engine can be started and stopped at any time, since there is no risk of overheating such an engine.

- At the same time, pumps of this type are characterized by high efficiency, high-quality materials at the heart of the structure, as well as relatively low weight.

- Also, such pumps work with a lower noise level when compared with other analogues.

However, before buying, we still recommend that you contact the specialists of our online store. We will be happy to advise you on all your questions, as well as help you choose the pump that is suitable for your situation.

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 2.52 |

| Feed height, m | 28 |

| Power capacity, kW | 0,37 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 2.52 |

| Feed height, m | 28 |

| Power capacity, kW | 0,37 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 1.8 |

| Feed height, m | 15 |

| Power capacity, kW | 0,25 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 1.8 |

| Feed height, m | 15 |

| Power capacity, kW | 0,25 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 3.36 |

| Feed height, m | 38 |

| Power capacity, kW | 0,75 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 8.4 |

| Feed height, m | 85 |

| Power capacity, kW | 2,2 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 8 |

| Feed height, m | 14 |

| Power capacity, kW | 0,75 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 8 |

| Feed height, m | 18 |

| Power capacity, kW | 1,1 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 12.5 |

| Feed height, m | 21 |

| Power capacity, kW | 1,5 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 20 |

| Feed height, m | 20 |

| Power capacity, kW | 2,2 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 25 |

| Feed height, m | 24 |

| Power capacity, kW | 3 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 28 |

| Feed height, m | 30 |

| Power capacity, kW | 4 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 30 |

| Feed height, m | 35 |

| Power capacity, kW | 5,5 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 25 |

| Feed height, m | 48 |

| Power capacity, kW | 7,5 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 40 |

| Feed height, m | 50 |

| Power capacity, kW | 11 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 50 |

| Feed height, m | 51 |

| Power capacity, kW | 15 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 80 |

| Feed height, m | 47 |

| Power capacity, kW | 18,5 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 80 |

| Feed height, m | 54 |

| Power capacity, kW | 22 |

| Temperature (min), °C | -30 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 130 |

| Feed height, m | 52 |

| Power capacity, kW | 30 |

| Temperature (min), °C | -196 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 2.1 |

| Feed height, m | 50 |

| Power capacity, kW | 0,37 |

| Temperature (min), °C | -196 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 2.7 |

| Feed height, m | 80 |

| Power capacity, kW | 0,5 |

| Temperature (min), °C | -196 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 3 |

| Feed height, m | 60 |

| Power capacity, kW | 0,75 |

| Temperature (min), °C | -196 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 3.9 |

| Feed height, m | 80 |

| Power capacity, kW | 1,1 |

| Temperature (min), °C | -196 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 5.4 |

| Feed height, m | 90 |

| Power capacity, kW | 1,5 |

| Temperature (min), °C | -196 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 7.2 |

| Feed height, m | 100 |

| Power capacity, kW | 2,2 |

| Temperature (min), °C | -196 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 9.6 |

| Feed height, m | 120 |

| Power capacity, kW | 3 |

| Temperature (min), °C | -196 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 11.7 |

| Feed height, m | 65 |

| Power capacity, kW | 4 |

| Temperature (min), °C | -196 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 13.5 |

| Feed height, m | 80 |

| Power capacity, kW | 5,5 |

| Temperature (min), °C | -196 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 19.8 |

| Feed height, m | 70 |

| Power capacity, kW | 7,5 |

| Temperature (min), °C | -196 |

| Producer | ALUNAK |

| Pump capacity, cu.m/hour | 24 |

| Feed height, m | 80 |

| Power capacity, kW | 11 |