- Home

- Industrial pumps

- Pumps by industry, purposeThe barrier pump of the refinery of pollutantsHigh temperature pumps +400°CCryogenic pumps for liquids -196°CEx pump for biogas plantsATEX gas intake well filtrate pumping pumpBiogas Intake and Utilization Filtrate PumpWater pumps of producing wellsPumps for unloading and loading railway tanksPumps for lowering the flood water levelBilge pump Ex ATEX certificatePumps for agriculture and irrigationPumps for the food industryHydroponics (Fertilizer Dosing Systems)Pumps for woodworkingChemical pumpsPumps for housing and communal servicesEvaporator pumpsSteam boiler pumps, feed pumpsIndustrial pumps

- Industrial pumpsVacuum pumps type HBR, HBR and AVZScrew pumps for polluted water type 1B, ANSScrew pumps type A1 3B (oil, fuel oil)Vortex pumps type VK and VKSHorizontal pumps type DMetering pumps type NDCondensate pumps type KsCantilever monoblock pumps type KMCantilever pumps type K and KSBOil gear type НМШ, Ш (bronze)Monoblock PumpsOil and gasoline pumpsSand pumps type PR, PK, PB, P, GrATPE feed pumpsFeed pumps TsVK, AN, PDV, PDG (steam)Food pumpsPneumatic PumpsHand pumps - type R and BKFWaste-mass pumps type 2SM with reduced energy consWaste mass type SMFecal pumps type SD, SDVChemical monoblock type XMCentrifugal vortex pumps type AN, PN, PDV and CVKSectional centrifugal pumps, type CNS, CNSg, CNSgmGear pumps type НМШ, ШHose and tube pumpsPump station SILVER 100 /24CPumping units TsNBKFood pumps ZCDZENNF food pumpsFrequency inverter Hyundai N700Rotary gear pumps NRP ShCirculation pumps GHN, GHNM three-speedScrew pumps NRP Shn

- Rotary gear pumps NRP Sh

Rotary gear pumps NRP Sh

Purpose

Rotary gear pumps NRP Sh designed for pumping media with dynamic viscosity up to 8 Pa · s, density up to 1800 kg/m3 and temperature up to 100 °С, by special order with temperature up to 150 °C. The rotary vane pump is ideal for pumping viscous and highly viscous products in applications food, cosmetic and pharmaceutical industries.

The pumps handle low to very high viscosity media and are the ideal choice for gentle pumping delicate various media such as: dairy products, yeast, fats, melas, sugar syrup, fruit juices, chocolate, blood products, enzymes, toothpaste, cosmetic creams, animal feed, solvents, suspensions, chemicals, etc.

Application

- In the confectionery industry for pumping chocolate, paste, cream, molasses.

- In the dairy industry for pumping sour cream, yoghurt, cream, cottage cheese, curd grains.

- In the processing industry for pumping stews, lecho, caviar, minced meat, sauces.

- In the cosmetic industry for pumping creams, soaps, shampoos, concentrates, etc.

- In other industries.

Specifications

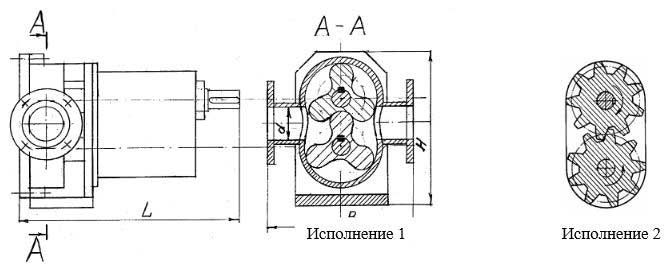

Pump rotors are sealed by mechanical seals. The rotary pump consists of two rotors rotating inside the case without touching each other. As the rotors rotate, the space between the pump casing and rotors are gradually filled with product, which moves in a certain volume to the discharge hole. The pumped product generates a continuous flow due to the verified tolerances between the rotors and housing, ensuring an efficient pumping process.

| Pump type | Feed, m3/h | Head, m | Installed capacity el. dv., kW |

Overall dimensions, mm | Weight, kg | |||

| L | H | B | D | |||||

| NRP Sh 0.2/80 typ 2 | 0.2 | 80 | 0.55 | 255 | 210 | 150 | 30 | 25 |

| NRP SH 4/80 typ 2 | 4 | 80 | 3 | 265 | 210 | 130 | 40 | 50 |

| NRP SH 6/50 typ 2 | 6 | 50 | 2.2 | 550 | 210 | 215 | 50 | 40 |

| NRP SH 10/40 typ 1 | 10 | 40 | 3-4 | 450 | 600 | 340 | 50 | 100 |

| NRP Sh 20/40 typ 1 | 20 | 40 | 7.5 | 450 | 600 | 340 | 50 | 100 |

Dimensions (edit)